New product development: safety first

By Linda Everis - 13 May 2015

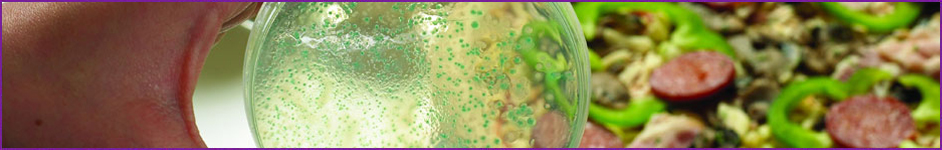

Over recent years, there has been much development of new food and drink products which are lower in salt, sugar and fat and thus offer a healthier

option to standard formulation products. Increased consumption of sugar has been linked to obesity, and increased salt consumption has been linked

to cardiovascular disease. However, by removing ingredients such as salt and sugars, there is the potential to affect the microbiological stability

of these reformulated products. This is because these ingredients have antimicrobial properties. Products may also be developed to be clean label

and therefore have no added preservatives.

Salt and sugar contribute to the safety and stability of products by reducing water activity. Water activity is an important controlling factor in

the prevention of microbial growth as it reduces the amount of water available for microorganisms to use. Preservatives are also used to prevent the

growth of organisms; for example, sorbate is often used to prevent yeast growth and hence spoilage of products. Studies carried out at Campden BRI

have shown that reducing sugar levels and removing preservatives decrease the stability of dilutable drink products and a barbecue sauce.

Reducing salt level can also impact on the microbiological stability of foods, as it is a power antimicrobial. One of the controlling factors given

in the ACMSF recommendations on the safety and shelf life of vacuum packed and modified atmosphere packaged chilled foods is salt level. A salt

level of 3.5% or more throughout the product can prevent C.botulinum growth. If the salt level is lower than this and one of the other

controlling factors (pH 5 or less, aw 0.97 or lower or a heat treatment of 90°C for 10 minutes) is not is place then the shelf life should be

limited to 10 days or less with respect to C.botulinum unless it can be proven by predictive modelling or challenge testing that C.botulinum

is not able to grow.

It is really important when re-formulating products or developing new products to consider the impact of the change on microbiological safety and

quality. In the first instance predictive microbiological models can be used to asses the growth of pathogens and/or spoilage organisms; then, if

deemed necessary, this can be followed up with inoculated challenge test studies using the relevant organisms. If you would like more information or

advice on use of models or would like to discuss challenge testing then please get in touch.

Linda Everis

+44(0)1386 842063

linda.everis@campdenbri.co.uk

About Linda Everis

Linda has a wealth of knowledge, experience and expertise from her time in Microbiological Analytical Services and Microbiology Safety and Spoilage. She joined Campden BRI in 1995 as a Senior Technician in the Microbiological Analytical Services group having graduated from the University of Wales Aberystwyth with a BSc in Biology.

Alongside the expert support that Linda provides to our members and clients, Linda conducts project work and research, and has been author and co-author of articles and papers for a variety of microbiological publications and Campden BRI reports.

Linda also lectures on shelf-life, challenge testing and predictive microbiology for our many training courses and seminars.