Foreign body identification

To discuss your needs

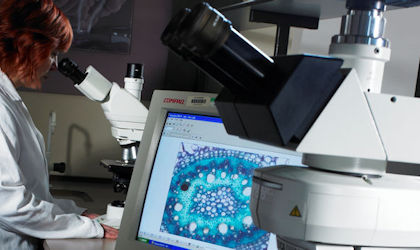

A foreign body is an unwanted physical object present in a food or drink product. Here at Campden BRI we have a dedicated Microscopy team who are able to identify many different types of foreign bodies, using our extensive expertise, techniques and suite of state-of-the-art equipment listed below.

Techniques and equipment

Light microscopy – stereo and compound microscopes

Stereo Microscope – Used to assist with visualising minute detail and gain a detailed view of the foreign body.

Compound Microscope – Commonly used to identify organic matter and surface deposits removed from a foreign body which may indicate contact with a product.

X–ray microanalysis

A non–destructive technique which allows the elemental composition of a sample to be identified. Elemental composition is a key feature in identifying a wide range of samples. In addition to determining the elemental composition of a sample, the Carl Zeiss Evo 60 Scanning Electron Microscope, alongside the x-ray analyser can be used to map the distribution of elements over an area of a sample.

Fourier Transform InfraRed spectroscopy (FT–IR)

A technique which produces a spectrum of infrared absorption of a sample when an infrared beam is projected onto it. This spectrum is then compared against a vast library of reference data.

Phosphatase test

Heat processing of many animal/insect samples can denature enzymes within the tissues of the sample. A phosphatase test is a chemical test which aims to identify whether the phosphatase enzyme, is active or if has been denatured due to heat processing.

Blood test

A chemical test can be used to determine the presence of peroxidase-like activity, which is exhibited by the haemoglobin of all red blood cells. This test will give a presumptive result for the presence of blood.

You may also be interested in

Key services

Packaging down the microscope

Microscopy use a range of techniques to examine packaging materials including plastic and metal.

Structure and physical properties

Methods for objective characterisation of food structure and physical properties.

Foreign body identification scheme

Run independently from our own foreign body laboratory, the FOBS scheme enables other laboratories to check their competence in the identification of foreign bodies.

Cereals and milling services

Cereals and milling testing services information, pricing and submission.

Meat, poultry and seafood analysis

Analysis supporting meat, poultry and seafood suppliers, manufacturers and retailers.

Food analysis and testing

Explore our analysis and testing related courses including; calculating meat content and wine analysis

Are you getting the most from your Membership?

Watch our membership FAQ videos and find out more about Member Service Account spending, Member Interest Groups, help and advice

Where we refer to UKAS Accreditation

The Campden BRI group companies listed below are both accredited in accordance with the recognised International Standard ISO17025:2017 by the United Kingdom Accreditation Service (UKAS). The accreditation demonstrates technical competence for a defined scope of methods, specific to each site, as detailed in the schedules of accreditation bearing the testing laboratory number. The schedules may be revised from time to time and reissued by UKAS. The most recent issue of the schedules are available from the UKAS website www.ukas.com

Campden BRI (Chipping Campden) Limited is a UKAS accredited testing laboratory No. 1079 Campden BRI (Nutfield) is a UKAS accredited testing laboratory No. 1207