From February 2015 newsletter

From February 2015 newsletter

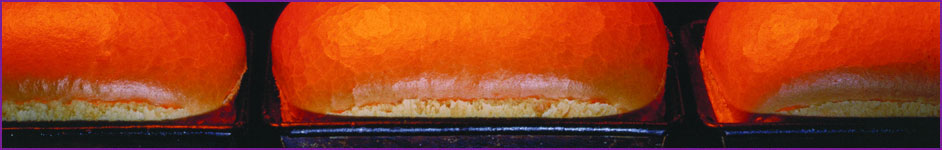

Improving oven efficiency during bread baking

Typical commercial ovens could reduce gas use by nearly 5%, which equates to over £14,000 per year. This is the key finding from recent research which has looked to measure and improve oven gas balance during bread baking, in order to reduce heat loss and energy usage. Specific focus was on the inlet burner air and outlet flue gases of a 3–zone pilot oven in order to calculate savings for a typical commercial travelling oven.

Energy intensive

Baking is the most energy intensive process in the production of baked goods, being responsible for 35–45% of total site energy costs. The amount and type of food in the oven can significantly affect gas flows and energy usage.

One of the unknown gas flows during baking is the volumetric rate of gas released from products, which must be known before gas flows can be balanced. The volume of gas produced by bread varied significantly by oven zone – and was 6–fold greater in zone 3 than zone 1 – while gas from combustion was consistent. Reducing the amount of exhaust air to match the burner air, by using sensors, a ratio controller and a variable speed fan, improved oven balance, and gave an energy saving of 42% in the pilot oven.

Contact: Support Team

+44(0)1386 842291

support@campdenbri.co.uk