Factory audits and sampling

To discuss your needs

Running a food processing or food service operation is a complex matter. Simple faults that might give rise to food safety problems can easily go un-noticed, so it is always useful to have an outside pair of eyes to assess the situation. Much of Campden BRI's research and work related to hygienic design and practice is factory based. We can help food manufacturers and retailers understand where the greatest risks of product contamination are likely to occur and thus determine best hazard control practices. Our expertise in such matters also allows us to advise on best hygienic practices and to be able to compare and contrast operations.

Allied to this is advice and practical assistance with the development of environmental monitoring programmes with capabilities and facilities to detect, analyse and measure environmental contaminants arising from microbiological (including specific pathogens), chemical and physical sources. Following sampling, advice can be given on sampling validation, sample transport, results interpretation, action plans for troubleshooting and environmental clean-up and enhanced sampling to allow return to routine practices. We can also help kit manufacturers validate new environmental sampling techniques.

Key services

COVID-19 (SARS-CoV-2)

Environmental testing and prevention to help the food industry control SARS-CoV-2.

Disinfectant testing

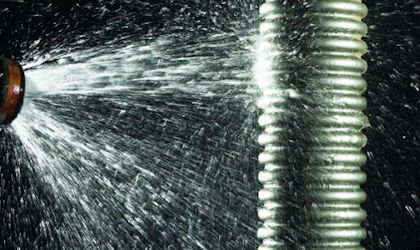

Ensuring that factories are cleaned and disinfected effectively in a timely manner.

Factory audits and sampling

Help in understanding where risks of product contamination are likely to occur.

Hygiene training courses

Explore our hygiene related courses including; Allergen control and Food processing hygiene management

Are you getting the most from your Membership?

Watch our membership FAQ videos and find out more about Member Service Account spending, Member Interest Groups, help and advice

Where we refer to UKAS Accreditation

The Campden BRI group companies listed below are both accredited in accordance with the recognised International Standard ISO17025:2017 by the United Kingdom Accreditation Service (UKAS). The accreditation demonstrates technical competence for a defined scope of methods, specific to each site, as detailed in the schedules of accreditation bearing the testing laboratory number. The schedules may be revised from time to time and reissued by UKAS. The most recent issue of the schedules are available from the UKAS website www.ukas.com

Campden BRI (Chipping Campden) Limited is a UKAS accredited testing laboratory No. 1079 Campden BRI (Nutfield) is a UKAS accredited testing laboratory No. 1207