Chorleywood Bread Process – how it’s changed industry

By Gary Tucker - 25 October 2019

If there is an iconic baking process that has come out of the British tradition, it would be the Chorleywood Bread Process (CBP) developed in 1961 by scientists here at Campden BRI (then known as the British Baking Industries Research Association (BBIRA)). CBP revolutionized the UK bread baking industry. It offered a loaf that is cheaper and softer.

For nearly six decades, CBP has now been adopted in many parts of the world from Australia to South Africa, Turkey and even France where some stick loaves are made the Chorleywood way, although not for the classic French baguette. What makes the Chorleywood way such a success across borders? What are the key elements of CBP that it has had such a positive impact on the bread-making sector?

All bread-making processes mainly rely on a small number of basic steps, and consecutively these are: Mixing, Proving/Fermenting, Baking and Cooling/Packing.

Traditional bread making is a slow process requiring several steps with manual intervention. It involves lengthy fermentation times in which the dough structure develops over many hours. The economic problem with this is that the time and effort required does not lend itself to being used in high throughput bakeries. Our need for bread as a staple part of our diet is such that loaves must be produced at rates of several thousand each hour in several large bakeries. It would be a struggle to feed the growing population without fast and efficient bread-making processes such as the CBP.

The CBP differs from traditional bread making primarily in one aspect of the process – the mixer operates at a much higher rate of shear. The mixer imparts energy to the dough at a fast rate so that the dough develops its desirable properties in a few minutes. The quantity of energy delivered to the dough determines the endpoint of mixing and not the time of mixing. This process will be described later in the section on mixing. Another critical point is that when the dough exits the high shear mixer, it is at its optimal condition. This is not the case with traditional mixing in which the dough needs to rest after mixing so the yeast and natural enzymic reactions can make the changes over several hours.

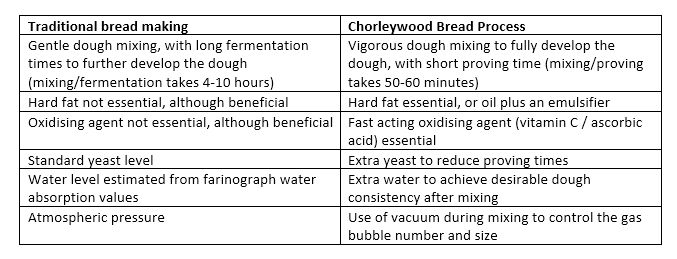

Mixing under high shear was the main change introduced with the CBP. Even the same base ingredients are used in all bread-making processes – flour, water, yeast and salt. There are, however, two different ingredients introduced with the CBP; the use of a fast-acting oxidizing agent (Vitamin C/ascorbic acid) and a small proportion of hard fat or emulsifier. These are required because of the challenge presented from the rapid changes occurring in the dough.

Dough Mixing Step – The Major Innovation

Mixing of dough is the stage in which several chemical, microbiological, and physical processes start.

These include blending and hydration of flour components, yeast metabolism and enzymatic reactions,

entrainment of small gas bubbles in the dough and development of the gluten matrix. For the no-time dough,

as typically produced in modern plant bakeries using the CBP, the mixing element is responsible for

delivering dough with an appropriate structure and rheology for further processing. Additional water is

required during CBP mixing because the dough does not require a long time after mixing when it softens up.

Optimization and control of the mixing endpoint is an important operation for making high-quality bread. A CBP dough should be at its optimum condition at the end of mixing. All subsequent processing stages that involve mechanical dough handling have the potential to damage the delicate network of gas cells. Mixing to a fixed time is used to determine the endpoint with most spiral and bar mixers; as found in craft and medium-sized bakeries. Whereas higher-intensity mixers, such as those used for the CBP, mix to a fixed energy input per kg of dough. This was found to give a more consistent endpoint than mixing to time.

There are established mixing energies for ‘standard UK bread flours’ of around 11 Wh/kg dough, based on work at the British Baking Industries Research Association at Chorleywood (now Campden BRI). The typical mixing time in a high shear mixer is around three minutes, but it can range from two to four minutes depending on flour strength, compared with 10-15 minutes for many other types of dough mixer. Stronger flours with higher quality protein require more energy to develop the gluten, possibly 12-13 Wh/kg or even higher. This tends to cause the dough temperature to rise as a result of increased frictional heat. An ideal dough temperature for a CBP process is around 30°C. Where high energy levels are used to develop dough, the mixing bowl can be fitted with a cooling jacket to reduce the dough temperature. Warm dough is likely to be soft and sticky on the surface, making it difficult to process and causing it to prove too fast.

Before the CBP, bread dough mixing occurred under atmospheric conditions in which there was easy access for air to get entrained into the dough. Many experiments were carried out at the BBIRA to explore the benefits of using different levels of vacuum during mixing and holding the vacuum for different times. It was discovered that a partial vacuum created a high number of smaller air bubbles in the bread, and this has resulted in the fine structure in sliced sandwich bread. The network of numerous small bubbles also contains thinner walls between the bubbles, and this, in turn, makes the bread softer. Almost all, if not all, of the major plant bakeries, use a partial vacuum during the later stages of mixing.

The use of pressure at the start of mixing was not part of the original CBP but came in over 20 years later. Pressure serves to introduce more air into the mixer so that the oxidizing agent, ascorbic acid, can operate more effectively. Without air, ascorbic acid is a reducing agent and will not develop the gluten network effectively. It is the oxygen in the air that triggers the oxidation of ascorbic acid, and this, in turn, oxidizes the gluten. Pressure-vacuum mixing was the subject of a Baker-Perkins patent in 1995.

Large Bakers as Early Adopters

Interestingly, when the CBP was first introduced in the 1960s, it was expected to create more interest

with the small bakers. Large bakeries were not expected to invest in changing their continuous dough

mixers and experience months of disruption. CBP, however, was adopted by all of the major bakeries but few

of the small ones, and this is the case up to this day.

Table 1: Key differences between traditional bulk fermentation and CBP.

CBP’s Major Benefits

Bread made using the CBP has many advantages over the traditional methods. No wonder it has won acceptance in more than 30 countries. Modern lifestyles and longer shelf-life, which means savings in consumer’s wallets have contributed to its success.

First, the fast and efficient processing with CBP lends itself to improved consistency in shape, size, and crumb structure of baked loaves. Also, a higher level of automation can be implemented, which further improves consistency and reduces costs. Soft, springy, white bread loaves are what consumers want.

CBP allows larger-scale production of bread than was previously possible, reducing the cost of bread production and benefiting consumers in keeping the price low. The total time to make a bread loaf tends to be under four hours from flour to sliced bread.

Third, bakeries do not need the space for containers for bulk fermenting dough. Less wastage also results during summer and winter when temperature control of the dough is challenging.

Fourth, CBP enables a higher proportion of UK wheat to be used in the flour grist, providing a massive economic benefit to the UK wheat growers, millers and bakers. Some 80 percent of the wheat used for bread is now UK-grown, which compares with 30 percent before the CBP. This reduces costs and significantly reduces the “food miles” associated with the bread that’s sold.

Fifth, sliced bread has a finer (and whiter) crumb structure and is softer because of the thinner walls between gas cells. It will stay softer for longer.

Finally, the extra water required to achieve the desired dough consistency in the mixer increases the yield slightly, saving cost.

We’re continually examining innovative technologies. How can fat, sugar and calories be reduced in bakery products? What are the novel technologies that can reduce waste during processing?

This article was first published in the September 2019 edition of The World of Food Ingredients.

Contact: Support Team

+44(0)1386 842291

support@campdenbri.co.uk