Shelf-life - testing and studies

To discuss your needs

Get the optimal shelf-life performance from your products

Short shelf-life performance can critically impact on the value of your product, both to you and your customers.

Campden BRI is a leading provider of testing and analysis services to the global food industry. We take a holistic approach to shelf-life testing that provides insight into all aspects of the food. We can assess how your product performs over time and identify the changes to ingredients, packaging or to other contributory factors that will help lengthen shelf-life across a variety of product types, to deliver results you can trust.

Using state-of-the-art facilities and the latest methods and technology, you can be sure of a high-quality service that will reduce the risk of product recalls and identify the causes of reduced shelf-life, helping you to improve your products, processes and ultimately your profitability.

When do you need to perform shelf-life studies

- Change in distribution conditions

- New product formulations

- To verify a new production or storage condition

- Change of packaging material

What you can expect from a partnership with us

As your testing partner, we are passionate about solving your challenges. Some of our services are detailed below but this is not an exhaustive list. Talk to us about any shelf-life issues you may have and we can identify appropriate action. Taking a case-by-case approach our experts can carry out the following analysis and testing:

- Organoleptic parameters: appearance, colour, odour, flavour

- Consumer acceptability

- Texture using a texture analyser

- Physical and chemical parameters: pH value, viscosity, density, monitoring of ingredient formulation

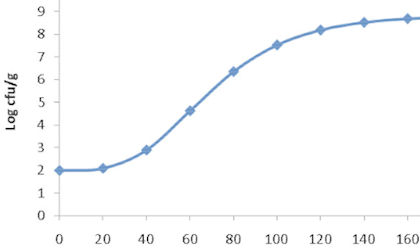

- Microbiological parameters: microbial types and levels, compliance with specifications and predictions

- Lipid oxidation

- Nutrient stability

- Active ingredients and claim substantiation

In addition, shelf-life studies include:

- Studies of “temperature abuse” or “cold chain breakage” (e.g. during transportation, storage, at point of sale or at end-consumer before consumption)

- Simulations with predictive models calculating the potential growth rate of microorganisms

- Accelerated shelf-life to predict the real shelf- life, by using special storage conditions (light, temperature, humidity, etc.) to ease the acceleration of chemical reactions that would take longer in normal conditions

- Challenge studies with various spoilage or pathogen organisms such as Listeria monocytogenes or yeasts

- Packaging performance and interaction evaluation

For more information on our shelf-life studies service and how we can help, please contact us.

Key services

COVID-19 (SARS-CoV-2)

Environmental testing and prevention to help the food industry control SARS-CoV-2.

Microbiological analysis and testing

Covering pathogens, spoilage organisms, and indicator organisms

Microbiological shelf-life

Product safety, retaining sensory, microbiological and chemical characteristics.

Microbiological methods evaluation

Evaluating microbiological methods, validation and interpretation.

Heat resistance

Determine whether the process you are using will be sufficient to achieve your aims.

Detection and control of foodborne viruses

Foodborne viruses are a safety challenge for a range of foods.

Shelf-life training courses

Explore our shelf-life related courses including; Setting shelf life: how to do it better and Designing microbiologically safe foods

Are you getting the most from your Membership?

Watch our membership FAQ videos and find out more about Member Service Account spending, Member Interest Groups, help and advice

Where we refer to UKAS Accreditation

The Campden BRI group companies listed below are accredited in accordance with the recognised International Standard ISO/IEC 17025:2017 by the United Kingdom Accreditation Service (UKAS). The accreditation demonstrates technical competence for a defined scope of methods, specific to each site, as detailed in the schedules of accreditation bearing the testing laboratory number. The schedules may be revised from time to time and reissued by UKAS. The most recent issue of the schedules are available from the UKAS website www.ukas.com. Campden BRI (Chipping Campden) Limited is a UKAS accredited testing laboratory No. 1079