Detection and control of foodborne viruses

To discuss your needs

Foodborne viruses are a safety challenge for a range of foods including ready–to–eat products, fresh produce, bivalve shellfish and pork products. While viruses cannot grow in or on foods, they can be carried on or in foods. Three viruses are of primary concern to food safety: norovirus (NoV), hepatitis A (HAV) and hepatitis E (HEV).

We offer a range of services to detect and control viruses in foods:

- Detection of norovirus GI / GII hepatitis A and hepatitis E. Tailored guidance on foodborne viruses, the threat they pose to specific products and options for their control – including trials to validate specific approaches

- Bespoke training and briefing sessions on viruses as a hazard, their control and how to handle contamination incidents

How do viruses get into food?

The foodstuffs mainly at risk from contamination with NoV and HAV are those which are lightly processed, eaten raw or ready-to-eat foods – for example, salad vegetables, soft berry fruits and shellfish. HEV may be found in undercooked or minimally processed pork meat products. Contamination of food with foodborne viruses can potentially occur anywhere along the supply chain.

How can foodborne viruses be detected?

Viruses do not multiply in or on foods, can often be present in very low numbers and cannot readily be cultured. Despite being challenging to detect, genomic material from viruses can be found. However, viruses remain detectable after the virus is rendered non-infective, which makes it difficult to determine whether the virus is active or inactive (i.e. a threat to safety or not).

How can viruses be controlled?

The best means of control is prevention – stopping pathogens (including viruses) from entering the food supply chain in the first place. Once viruses enter the food supply chain, further control measures may have to be taken to ensure the safety of the food. Therefore, gaining an understanding of the survival and persistence of foodborne viruses on foods and in the environment, as well as the assessment and validation of antimicrobial treatments against viruses is an important area for the food industry. Information on work we have done in this area can be found here.

Key services

COVID-19 (SARS-CoV-2)

Environmental testing and prevention to help the food industry control SARS-CoV-2.

Microbiological analysis and testing

Covering pathogens, spoilage organisms, and indicator organisms

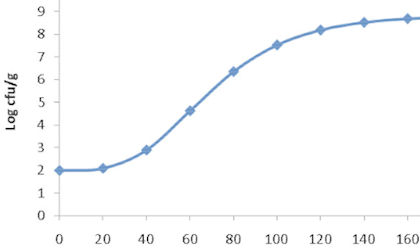

Microbiological shelf-life

Product safety, retaining sensory, microbiological and chemical characteristics.

Microbiological methods evaluation

Evaluating microbiological methods, validation and interpretation.

Heat resistance

Determine whether the process you are using will be sufficient to achieve your aims.

Detection and control of foodborne viruses

Foodborne viruses are a safety challenge for a range of foods.

Microbiology training courses

Explore our microbiology related courses including; Understanding microbiology for non microbiologists and Setting shelf life: how to do it better

Are you getting the most from your Membership?

Watch our membership FAQ videos and find out more about Member Service Account spending, Member Interest Groups, help and advice

Where we refer to UKAS Accreditation

The Campden BRI group companies listed below are accredited in accordance with the recognised International Standard ISO/IEC 17025:2017 by the United Kingdom Accreditation Service (UKAS). The accreditation demonstrates technical competence for a defined scope of methods, specific to each site, as detailed in the schedules of accreditation bearing the testing laboratory number. The schedules may be revised from time to time and reissued by UKAS. The most recent issue of the schedules are available from the UKAS website www.ukas.com. Campden BRI (Chipping Campden) Limited is a UKAS accredited testing laboratory No. 1079