Food cooking or reheating instructions

To discuss your needs

Ensure that your back-of-pack cooking instructions deliver safe and good quality products by using our customer cooking verification and related services.

“I use Campden BRI for cooking instruction validation as they provide a full temperature profile for the cooking process which will allow us to review what happens during the cooking times and see the temperature profile for compliance to 70°C for 2 mins. Campden BRI will also cook the product on if the 70°C for 2 mins has not been achieved which will then indicate required cooking instructions”

– Fiona Houston, Food Technologist / Company Director at FNH Solutions

Many products, often classed as ready-to-cook or ready-to-heat, are totally reliant the on consumer cooking to make them safe for consumption. It is therefore vital that back-of-pack cooking instructions are generated using a method that accounts for variation in appliance performance and heating method.

Getting this wrong could result in consumers routinely undercooking products at home and putting themselves at risk! The BRCGS outline an expectation for fully validated instructions, as well as this being a requirement in most retailers’ codes of practices.

There’s a whole lot more on offer alongside cooking instruction verification – including our new 'cooking energy and cost rating’ service. Get in touch to book instruction trials or explore other instruction services.

Cooking instruction verification and generation services

Our procedures for cooking instruction verification have been developed over 30 years to ensure accurate results which account for appliance variations. This core service was established from knowledge gained in research projects developed by Greg Hooper, and Greg’s knowledge and expertise still forms the backbone of our cooking instruction service offering.

For further details on what would be included within a typical instruction verification/generation trial, see our cooking instruction verification and generation services.

More cooking instruction services

Our technical experts have unrivalled experience and knowledge and there’s a whole lot more on offer alongside cooking instruction verification. Our services include:

- Defrosting generation/verification.

- Fibreoptic thermometry to measure time and temperature profiles within a microwave.

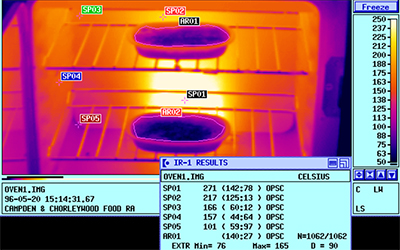

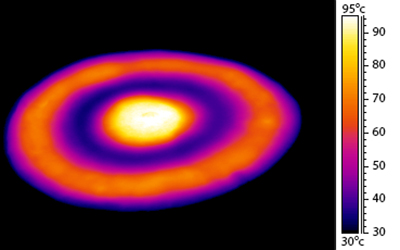

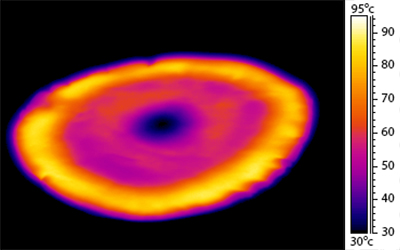

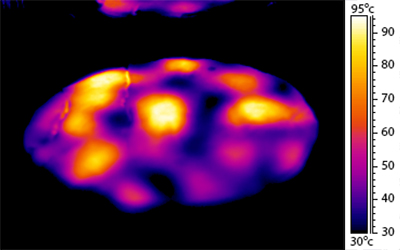

- Thermal imaging to access heating patterns and measure maximum product/packaging temperatures.

- Abuse Testing – put your products to the test and see what issues you are challenged with? How do your products stand up to the variability of appliances?

- Thermal Safety – is there a high risk of thermal injury to the consumer? Can packaging withstand the required heating time? What happens if a product is heated beyond its recommended cook time?

- Practical safety of heating products for sensory only purposes.

- Cook loss data.

- Trouble shooting and problem solving – the cooking instruction used by consumers is the last step before products are eaten and getting it right is critical. Success or failure of a product depends on this step and even slight tweaks of the instruction can have a huge different on the cooked quality of a product.

Air fryers

The variation in cooking performance between different brands and designs of these popular cooking appliances makes cooking instruction verification a challenge. See our dedicated page for details of air fryer services, research and blogs.

Cooking energy and cost rating

We now offer an exciting new service where energy usage and cost are measured in conjunction with the instruction verification/generation trial. We expect that a move to better inform consumers of the cost of cooking (through back-of-pack or website, for example) will be of considerable benefit to consumers, which will in turn benefit the manufacturers and retailers who provide this information.

Equipment and techniques

We use a range of calibrated equipment to encompass all reasonable worst-case scenarios, including domestic thermal ovens (gas electric and fan-assisted), air fryers, over 50 different microwaves etc. and different temperature measurement techniques to ensure accurate product temperature data during and after cooking.

Key contacts

About Greg Hooper

Greg has worked here at Campden BRI since 1990, after studying Applied Science (Physics and Chemistry). As part of his extensive knowledge and experience in thermal processing and microwave cooking, he was instrumental in setting up the microwave heating category rating system used in the UK, and has travelled internationally assisting and advising on the safe development of microwave products and rating systems.

About David Whittaker

David is a thermal and non-thermal processing specialist and has expertise across many food and beverage sectors.

David also delivers many thermal processing training courses and has a real passion for communication in this area, having spoken at several conferences and seminars on the topic, as well as contributing to Campden BRI guidelines.

About Lucinda Sturla

Luci graduated from the Royal Agricultural University with a degree in International Food and Agribusiness management in 2016. Before joining Campden BRI Luci, a trained chef, travelled the UK and abroad catering for private events and functions modifying menus and methods to adapt to clients’ individual tastes, dietary requirements, and nutritional goals.

Luci joined Campden BRI in 2020 and now looks after the Cooking Instruction Services team, generating, modifying, and verifying cooking instructions for all retailers using appliances such as Ovens, Microwaves, Hobs, Grills, Air-fryers, Deep-fat fryers, Steamers, and Toasters. The benefit of Luci’s background allows her to understand the culinary requirements in achieving both safely cooked products whilst ensuring organoleptic quality.

You may also be interested in

- Cooking energy and cost rating service | White paper

- Air fryer cooking instructions | Blog

- Air fryer cooking challenges | Blog

- Heating characteristics of domestic air fryers – technical challenges affecting cooking instruction validation | White paper

- BRC Issue 8: Cooking instruction validation | White paper

Key services

Heat process validation

Many factors affect the amount of heat delivered, the product it contains, and the degree of mixing during the process.

Food product development

Developing new food and drink products is a complex process, we can help across the full range of food types.

Food cooking or reheating instructions

Knowledge and expertise for microwave and conventionally heated products.

New technologies services and information

Exploring new and emerging process technologies for industry use.

Product development training courses

Explore our product development related courses including; New product development and HACCP in new product development

Are you getting the most from your Membership?

Watch our membership FAQ videos and find out more about Member Service Account spending, Member Interest Groups, help and advice

Where we refer to UKAS Accreditation

The Campden BRI group companies listed below are accredited in accordance with the recognised International Standard ISO/IEC 17025:2017 by the United Kingdom Accreditation Service (UKAS). The accreditation demonstrates technical competence for a defined scope of methods, specific to each site, as detailed in the schedules of accreditation bearing the testing laboratory number. The schedules may be revised from time to time and reissued by UKAS. The most recent issue of the schedules are available from the UKAS website www.ukas.com. Campden BRI (Chipping Campden) Limited is a UKAS accredited testing laboratory No. 1079