Heating characteristics of domestic air fryers – technical challenges affecting cooking instruction validation

30 July 2025 | Greg Hooper, Microwave and Thermal Process Specialist

Air fryers are excellent devices that are increasingly popular with consumers. This seems to be owed in part to their ability to deliver comparable quality and ‘crispness’ to other frying methods but by using much less oil / fat. Furthermore, their efficient cooking mechanism can reduce cook times compared to oven cooking, as well as provide consumers with the opportunity to reduce their energy consumption from cooking. Air fryers are available in a range of sizes and types, all of which work by circulating hot air around their cooking compartments at speed, which can give strong air currents and fast pre-heating. / fat. Furthermore, their efficient cooking mechanism can reduce cook times compared to oven cooking, as well as provide consumers with the opportunity to reduce their energy consumption from cooking. Air fryers are available in a range of sizes and types, all of which work by circulating hot air around their cooking compartments at speed, which can give strong air currents and fast pre-heating.

Campden BRI has received a high level of requests and interest from retailers, their suppliers and independent food product manufacturers for an air fryer cooking instruction service and wanting to know more about the performance of air fryers. For safely cooking food, the generally accepted thermal process is equivalent to two minutes at 70°C because this has been proven to reduce Listeria monocytogenes numbers one million-fold and adequately reduce or eliminate levels of E.coli and Salmonella. For foods not considered ‘ready-to-eat’, we must ensure that cooking instructions facilitate the consumer achieving this thermal process equivalent so that the food is safe to eat. BRCGS Global Standard Food Safety Issue 9 – Clause 5.2.4 is ‘Cooking (heating) instruction validation’, which mandates that on-pack cooking instructions must be fully verified and validated to ensure the instructions will deliver the required minimum thermal process using the worst case of all variables.

Despite their popularity and success, air fryers may now present a challenge to the industry with respect to on-pack cooking instructions. Our Process Innovation team have tested a range of basket, halogen and paddle air fryer models of varying cavity sizes and wattages, and found considerable differences in their ability to safely cook products using one instruction, with different cook times required for the same product when using the same settings. The results indicate that the variability in pre-heat time, temperature dial accuracy and cooking time could be barriers to generating, verifying and especially validating air fryer product cooking instructions.

This is not to say that air fryers do not work or that they do not cook food safely, but rather that the performance currently seems too variable across the wide range of available air fryers to be able to issue back of pack product cooking instructions that would work for every model.

Methodology

The following testing was applied to 10 disparate, domestic air fryers ranging from 800W to 1800W and including different models, types (basket, halogen, paddle) and cavity sizes. Air and product temperature trials were conducted using four calibrated, thin wire, type K thermocouples to measure and record probe tip temperatures every 10 seconds. From these readings, time / temperature graphs of the heating process were produced. / temperature graphs of the heating process were produced.

Five replicate trials were performed in each of the 10 air fryers for each of the five products (one model food product and four real food products).

For all product cooking trials (model food cook time determination and real food cook time determination), the air fryers were pre-heated for sufficient time to achieve a ‘steady state’ temperature (up to 20 minutes).

Dial setting accuracy

- The actual air temperatures achieved when dials were set to 160°C, 180°C and 200°C were determined.

- The thermocouples were located in the centre region of the air fryer, mid height in the basket.

- The (empty) air fryer was set to the indicated dial temperature and the air temperature monitored from an initial ambient temperature for at least 30 minutes.

- The average air temperature was calculated from readings taken over a 20 minute time period, once the air fryer had reached a steady state. The difference between the dial temperature setting and actual temperature was recorded.

- The pre-heat time (time to achieve a steady state air temperature) was determined.

Air temperature calibration at 180°C

- The difference in the dial setting required to achieve an actual calibrated air temperature of 180°C was assessed.

- The thermocouples were located in the centre region of the air fryer, mid height in the basket.

- The (empty) air fryer temperature settings were adjusted to achieve an actual air temperature of 180°C.

- The average air temperature was calculated from readings taken over a 20 minute time period, once the air fryer had reached a steady state of 180°C +/- 5°C. The difference between the actual 180°C and dial temperature setting was recorded.

Model food cook time determination

- A PTFE (Polytetrafluoroethylene), cylindrical ‘model sausage’ (approximately 167 grams) was heated to 70°C in the air fryer, using

both dial and calibrated air temperatures of 180°C, to determine the longest cook time required to achieve a product temperature of

70°C in each air fryer.

- ‘Model Sausage’ centre temperature was measured, as opposed to air temperature within the air fryer.

- Five replicate trials were performed for each dial and calibrated temperature in each air fryer.

- The model food was heated from an initial chilled temperature (5°C) to 70°C using a calibrated air fryer temperature of 180°C.

- The model food was heated from an initial chilled temperature (5°C) to 70°C using a dial air fryer temperature of 180°C.

Real food cook time determination

- Standardised chilled and frozen products of different characteristics were heated in the air fryer to achieve a minimum thermal process

equivalent to 70°C for two minutes and a final minimum temperature of 70°C, to determine the longest cook time required to

achieve this minimum thermal process in each air fryer.

- The following products were used: frozen beef burger, chilled beef burger, portion frozen hash browns, chilled spring roll.

- Product centre temperature was measured in four locations. Five replicate trials were performed for product in each air fryer and the longest cook time determined.

- For the chilled and frozen beef burger trials a calibrated air temperature of 180°C was used. One burger (approximately 114 grams) was cooked at a time.

- For the frozen hash brown trials a dial set temperature of 200°C was used. Six hash browns (approximately 235 grams, combined) were cooked at a time.

- For the chilled spring roll trials a calibrated air temperature of 180°C was used. One spring roll (approximately 65 grams) was cooked at a time.

Results and discussion

The results revealed a high degree of variation in pre-heat time, dial temperature accuracy, the time taken to achieve a safe cook and the final temperature of the food, across the ten different air fryers included in the study. The results are summarised in table 1 below.

Pre-heating performance

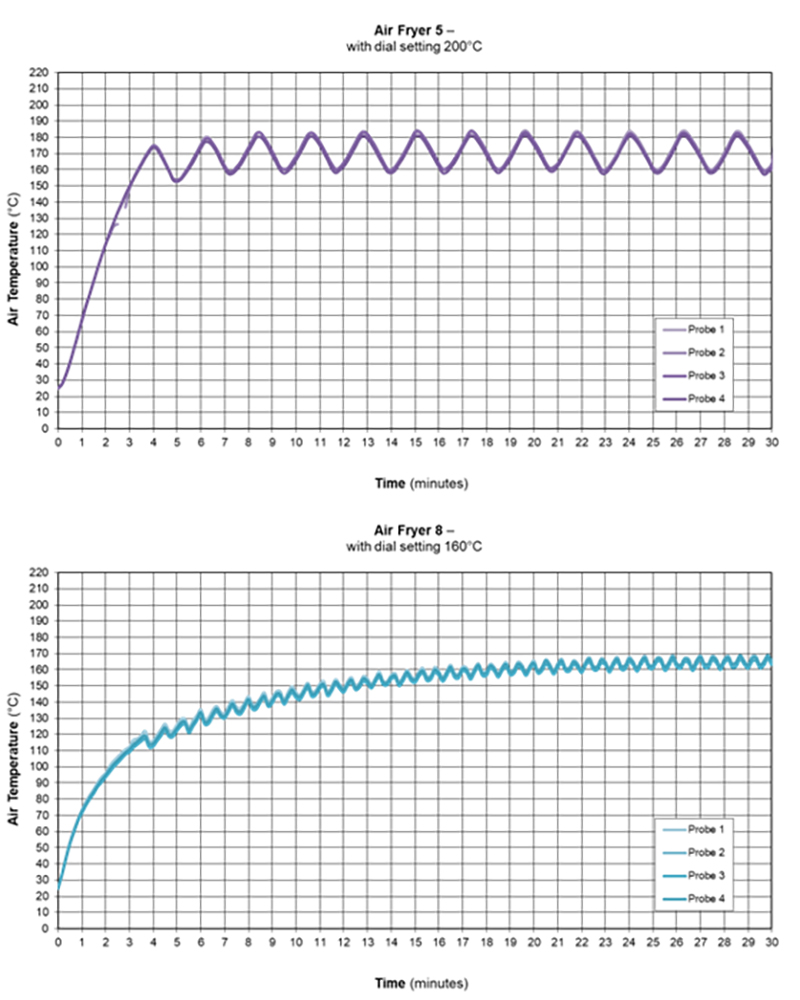

For all dial settings tested (160°C, 180°C and 200°C), the pre-heat time was determined to range from approximately 5 minutes to 20 minutes, with Air fryer 8 taking the longest time (see figure 1). Based on these results a ‘standard’ pre-heat time of 20 minutes was considered appropriate.

Figure 1: Air fryer 5 took approximately 8 minutes to reach an air temperature steady state, whereas air fryer 8 took approximately 20 minutes

| Air fryer | °C difference from actual temperature to dial setting 160°C | °C difference from actual temperature to dial setting 180°C | °C difference from actual temperature to dial setting 200°C | Necessary °C adjustment to dial setting to achieve an actual temperature of 180°C | Minutes taken to achieve 70°C | Minutes taken to achieve 70°C for two minutes and 70°C | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Model Sausage. Actual temperature 180°C | Frozen Burger. Actual temperature 180°C | Frozen Burger. Actual temperature 180°C | Chilled Burger. Actual temperature 180°C | Frozen Hash Browns. Dial temperature 200°C | Chilled Spring Rolls. Actual temperature 180°C | |||||

| Air fryer 1 Basket 7.6L 1700W | -4 | -3 | -4 | +5 | 11 | 10 | 21 | 14 | 13 | 12 |

| Air fryer 2 Halogen 9L 1200W 1400W | -7 | -6 | -6 | +14 | 10 | 10 | 25 | 17 | 12 | 8 |

| Air fryer 3 Basket 3L 1400W | -13 | -15 | -18 | +37 | 10 | 11 | 25 | 17 | 14 | 8 |

| Air fryer 4 Basket 4.1L 1400W | -1 | +1 | -4 | +7 | 10 | 10 | 20 | 13 | 10 | 8 |

| Air fryer 5 Toaster Oven 11L 1800W | -16 | -18 | -30 | +16 | 10 | 10 | 20 | 13 | 12 | 9 |

| Air fryer 6 Paddle 1.7Kg 1500W | -17 | -20 | -38 | +57 | 11 | 12 | 17 | 13 | 13 | 9 |

| Air fryer 7 Basket 4.2L 1400W | +4 | -1 | -3 | +4 | 10 | 9 | 17 | 13 | 11 | 8 |

| Air fryer 8 Halogen 10.6L 1300W | -1 | +2 | -8 | +5 | 10 | 9 | 23 | 16 | 12 | 9 |

| Air fryer 9 Basket 2L 800W | Unkown | Unkown | Unkown | Unkown | 12 | 12 | 24 | 17 | 17 | 10 |

| Air fryer 10 Basket 4L 1400W | +8 | -1 | -9 | +7 | 10 | 9 | 18 | 14 | 11 | 8 |

Note: Air fryer 9 operates at a fixed temperature setting, which is not defined or adjustable.

Variation in dial temperature performance

Dial settings of 160°C, 180°C and 200°C

- With a dial setting of 160°C the actual air temperature ranged from 17°C too low (Air fryer 6) to 8°C too high (Air fryer 10).

- With a dial setting of 180°C the actual air temperature ranged from 20°C too low (Air fryer 6) to 2°C too high (Air fryer 8).

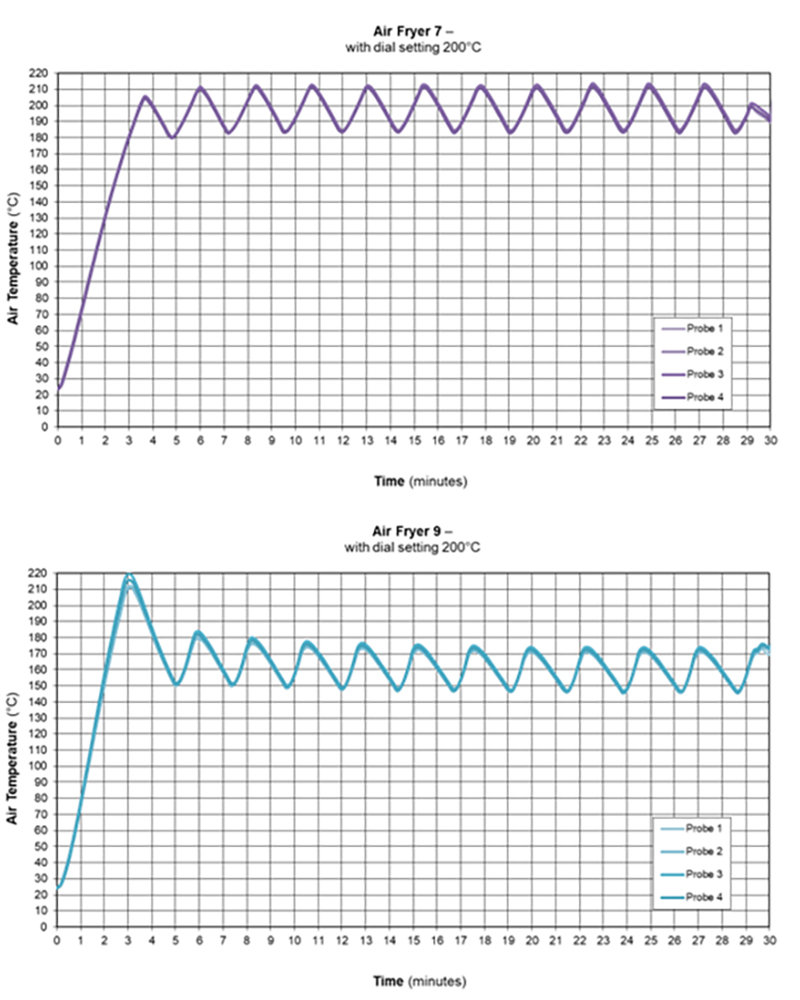

- With a dial setting of 200°C the actual air temperature ranged from 38°C / 39°C too low (Air fryers 6 and 9, respectively) to 3°C too low (Air fryer 7). See figure 2.

Figure 2: With a dial setting of 200°C, the actual air temperature was 3°C too low in Air fryer 7 and 39°C too low in Air fryer 9

To achieve an actual air temperature of 180°C

- To achieve an actual air temperature of 180°C (+/- 5°C), the dial settings ranged from 183°C to 220°C.

- All air fryers achieved a lower air temperature than that stated on the dial setting, ranging from 4°C too low and 57°C too low.

- Air fryer 6 was set to a dial temperature of 220°C, however this only achieved an average air temperature of 163°C, that is to say 57°C lower than the dial setting.

Variation in the time taken to achieve a safe cook on the same product

Model food cook time

Model Sausage - (actual calibrated air fryer air temperature of 180°C, where possible) – 10 to 12 minutes across the ten air fryers to achieve 70°C, with Air fryer 9 taking the longest time.

Model Sausage - (dial set to 180°C) – 9 to 12 minutes across the ten air fryers to achieve 70°C.

Real food cook time

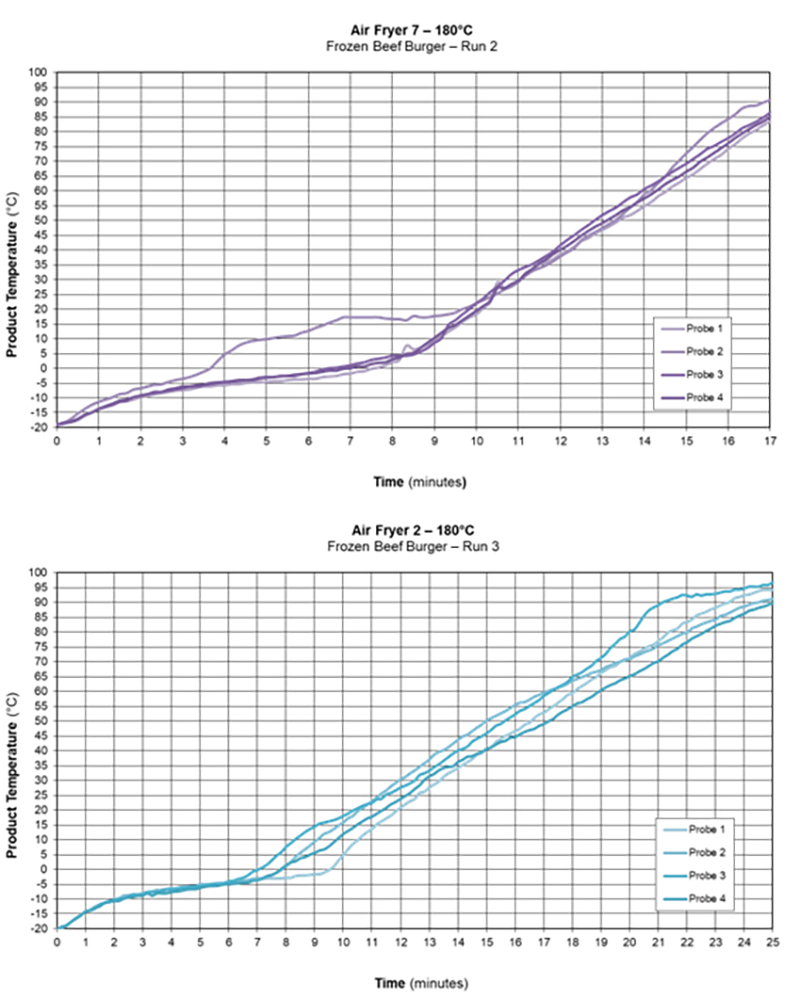

Frozen Burger (actual calibrated air fryer air temperature of 180°C, where possible) – 17 to 25 minutes across the ten air fryers to achieve a minimum temperature of 70°C and an equivalent process of 70°C for two minutes, with Air fryers 2 and 3 taking the longest times. See figure 3.

Figure 3: Air fryer 7 took approximately 17 minutes to deliver a cook equivalent to 70°C for two minutes to the frozen burger, whereas Air fryer 2 took approximately 25 minutes

For the frozen burger trials, out of the ten air fryers used, the longest time taken to reach a thermal process of 70°C for two minutes and a final minimum temperature of 70°C was by Air fryer 2 and Air fryer 3, both taking 25 minutes. Faster heating air fryers (Air fryers 6 and 7) took only 17 minutes to achieve this thermal process. If the shortest cook time of 17 minutes was used in the slower heating air fryers (Air fryers 2 and 3) it would have given final minimum temperatures of 45°C and 36°C.

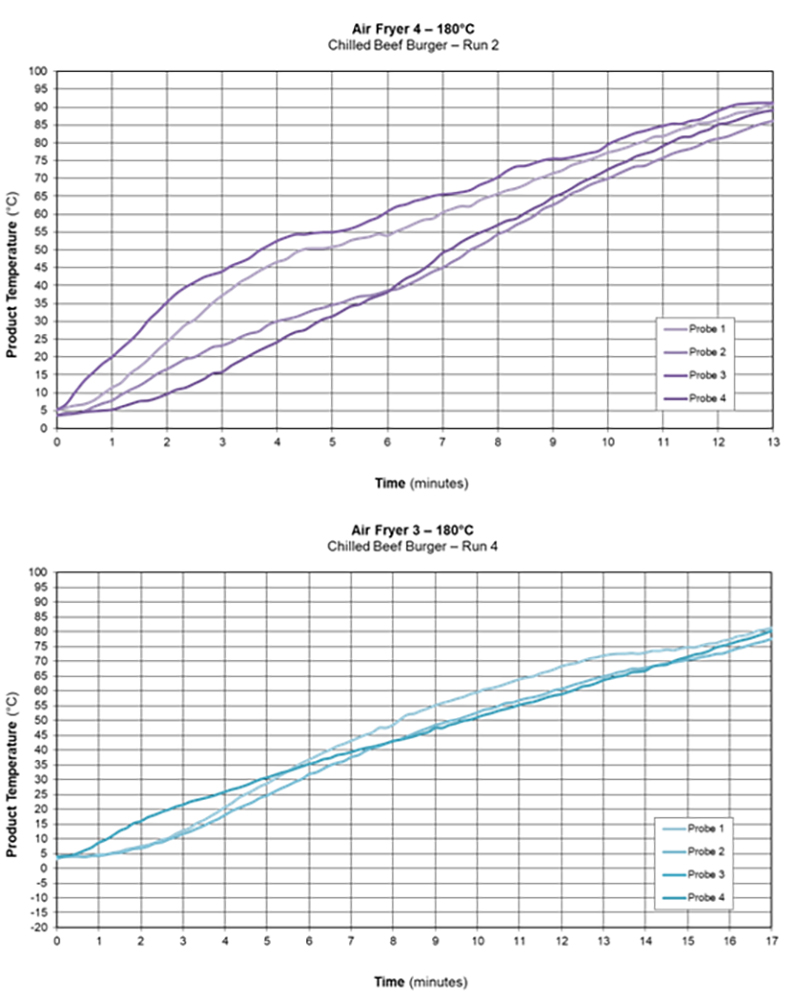

Chilled Burger (actual calibrated air fryer air temperature of 180°C, where possible) – 13 to 17 minutes across the ten air fryers to achieve a minimum temperature of 70°C and an equivalent process of 70°C for two minutes, with Air fryers 2, 3 and 9 taking the longest times. See figure 4.

Figure 4: Air fryer 4 took approximately 13 minutes to deliver a cook equivalent to 70°C for two minutes to the chilled burger, whereas Air fryer 3 took approximately 17 minutes

For the chilled burger trials, the longest time taken to reach a thermal process of 70°C for two minutes and a final minimum temperature of 70°C was by Air fryers 2, 3 and 9, all taking 17 minutes. Faster heating air fryers (Air fryers 4, 5, 6 and 7) took only 13 minutes to achieve this. If the shortest cook time of 13 minutes was used in the slower heating air fryers it would have given final minimum temperatures of 62°C, 59°C and 36°C.

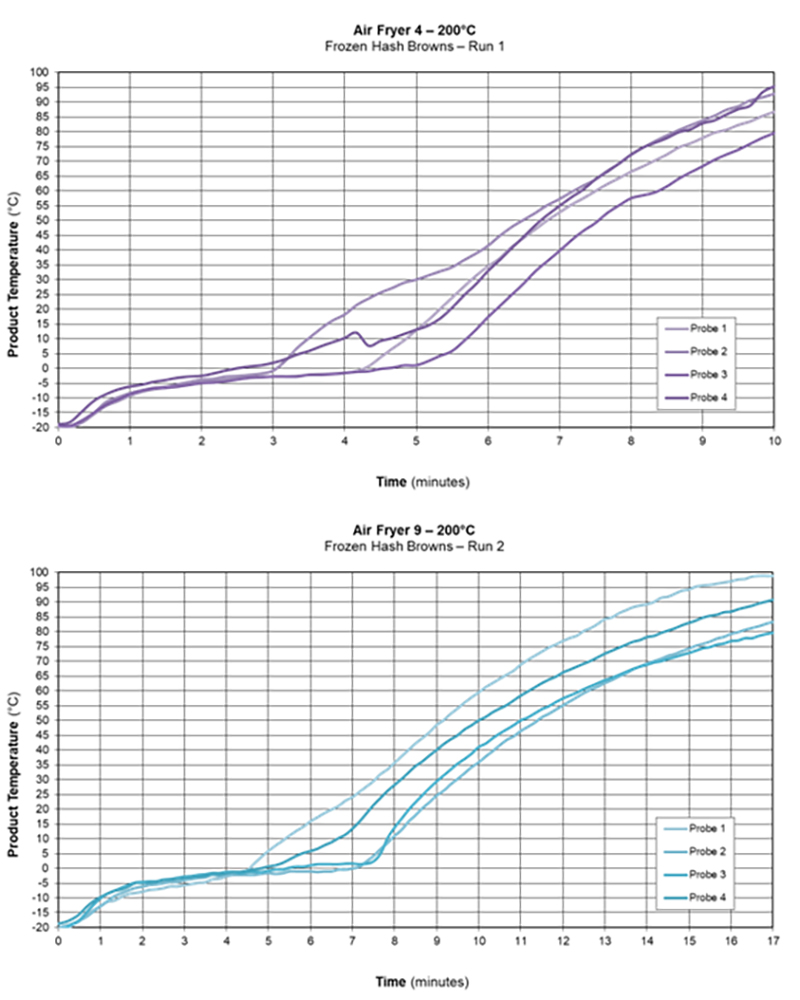

Frozen Hash Browns (dial set to 200°C) – 10 to 17 minutes across the ten air fryers to achieve a minimum temperature of 70°C and an equivalent process of 70°C for two minutes, with Air fryer 9 taking the longest time. See figure 5.

Figure 5: Air fryer 4 took approximately 10 minutes to deliver a cook equivalent to 70°C for two minutes to the frozen hash brown, whereas Air fryer 9 took approximately 17 minutes

For the frozen hash brown trials, the longest times taken to achieve the required thermal process and final minimum temperature were by Air fryers 3 and 9, taking 17 and 14 minutes respectively. A faster heating air fryer (Air fryer 4) took only 10 minutes to achieve this. If the shortest cook time of 10 minutes was used in the slower heating fryers, it would have given final minimum temperatures of 31°C and 37°C.

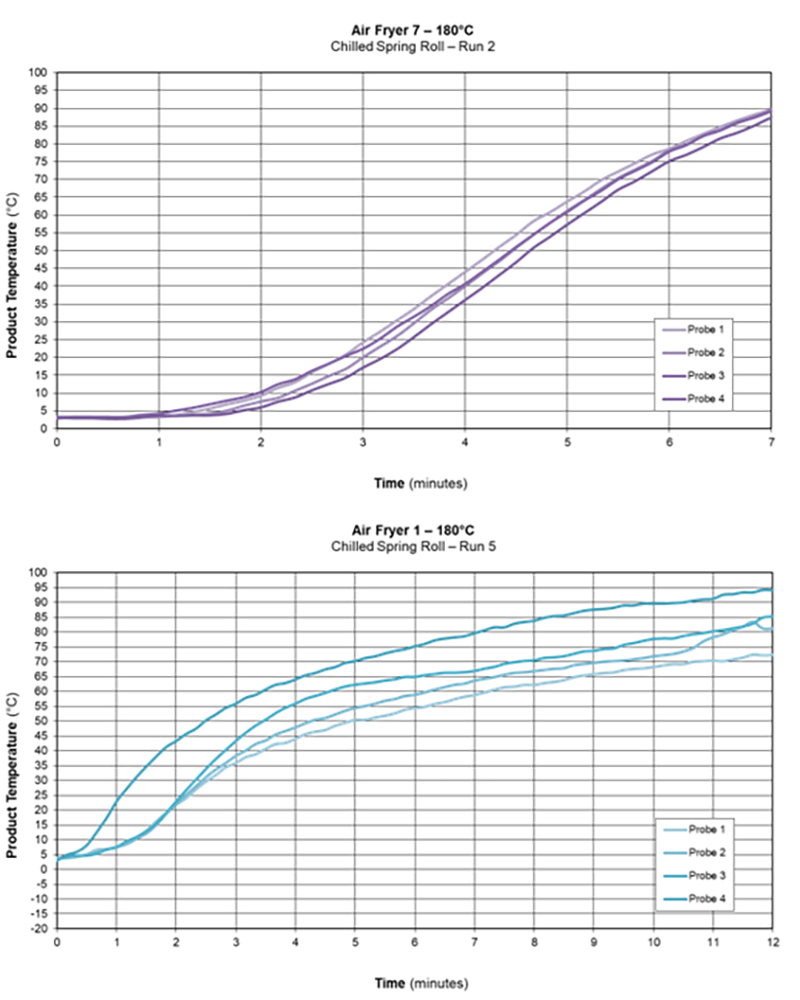

Chilled Spring Roll (actual calibrated air fryer air temperature of 180°C, where possible) – 7 to 12 minutes across the ten air fryers to achieve a minimum temperature of 70°C and an equivalent process of 70°C for two minutes, with Air fryer 1 taking the longest time. See figure 6.

Figure 6: Air fryer 7 took approximately 7 minutes to deliver a cook equivalent to 70°C for two minutes to the chilled spring roll, whereas Air fryer 1 took approximately 12 minutes

For the chilled spring roll trials, the longest time taken to achieve the required thermal process and final minimum temperature was by Air fryer 1, taking 12 minutes. A faster heating air fryer (Air fryer 7) took only 7 minutes to achieve this. If the shortest cook time of 7 minutes was used in the slower heating fryer, it would have given a final minimum temperature of 58°C.

For all of the food products, the required final minimum temperature of 70°C was not achieved when the shortest cook time (the cook time taken for faster heating air fryers to achieve the required thermal process and final minimum temperature) was applied to slower heating air fryers. Therefore, in the time taken for some air fryers to completely cook a product, other air fryers may not come close to the product reaching 70°C.

For all product cooking trials (model food cook time determination and real food cook time determination), the air fryers were pre-heated for a (minimum) time determined to achieve a steady state temperature. Due to the large variation in pre-heat time, using the air fryers from ‘cold’ would be expected to give an even greater range of performance.

Conclusions and next steps

Implications for retailers and suppliers

As explained in another of our white papers on cooking (heating) instruction validation, it is impossible to validate the safety of barbeque instructions due to wide differences in barbeque performance. Similarly, the performance variation (between different types / models) seen in this study of air fryers indicate that this relatively new cooking method may present a similar challenge for the generation, verification and validation of air fryer cooking instructions. For any air fryer cooking instruction validations to adequately fulfil BRCGS Global Standard Food Safety Issue 9 – Clause 5.2.4, the impact of this variation in air fryer performance needs to be carefully considered – i.e. could the variation in performance in consumers air fryers mean safe air fryer foods may not be consistently be produced?

The time required to achieve safe cooking in slower heating air fryers could amount to overheated, poor quality food for the consumer, whereas cooking instructions based on faster heating air fryers could pose serious food safety risks to the consumer when used with slower heating air fryers. Similar risks manifested in food poisoning cases in the 1990s, which were linked to products cooked in microwave ovens. It is important to understand that the wattage rating system subsequently developed for microwave ovens uses the wattage delivered to food, not the wattage used by the microwave oven. This was crucial in developing a system that would work for determining cook times that could work across the myriad of different microwave oven designs and models. The wattage rating stated for air fryers is the wattage used by the air fryer, which will not be equivalent to the power (heat) actually absorbed by the food. For example a large capacity, poorly insulated air fryer with low air circulation speeds might use much of its 1400W supply power heating the unit and air and replacing heat losses. This may not be as efficient / fast at heating a food as a 1400W air fryer with lower capacity, higher air speeds and better insulation, where much more of the 1400W is available for heating the food.

It is important to note that air fryers that heat products very quickly may not be ‘better’ than those that heat a product more slowly. Food products take time to achieve a desirable ‘cooked’ quality (such as browning and crisping) and just because one air fryer has achieved a safe minimum temperature (in this case 70°C) very quickly does not mean that the food product quality will be better than from an air fryer that has taken longer.

Another point for consideration is the pre-heat time taken for the air fryers to achieve their operating temperature. All the cook time testing performed in this research project used air fryers pre-heated for a time sufficient to achieve a steady state air temperature, but many consumers may be using their air fryers from ‘cold’. Given that the pre-heat time was found to vary from approximately 5 to 20 minutes for the air fryers tested, this could lead to further issues with variation of cooking performance.

The potential food safety implications explored here relate to foods that are not considered ‘ready-to-eat’. For ready-to-heat and raw / ready-to-cook foods we must ensure that cooking instructions facilitate the consumer achieving a thermal process equivalent to 70°C for two minutes. This is so that the food is safe to eat when cooked in any of the appliances to which the cooking instructions are intended to apply.

Worked example

Below is an example service for investigating air fryer cooking times using a range of air fryers:

- Three air fryers at a popular power rating (1400W).

- Two additional air fryers (for example, the slowest and fastest heating air fryers from this study).

- Perform five trials in each air fryer.

- Achieve a minimum temperature of 70°C and equivalent thermal process to 70°C for two minutes.

- Communicate results to the client (see below).

Due to the variability of air fryers explored in this study, Campden BRI would not consider this example testing to be a verification (as explained below).

| Air fryer | Minutes taken to achieve 70°C for two minutes and 70°C | |||

|---|---|---|---|---|

| Frozen Burger. Actual temperature 180°C | Chilled Burger. Actual temperature 180°C | Frozen Hash Browns. Dial temperature 200°C | Chilled Spring Rolls. Actual temperature 180°C | |

| Air fryer 1 Basket 7.6L 1700W | 21 | 14 | 13 | 12 |

| Air fryer 2 Halogen 9L 1200W 1400W | 25 | 17 | 12 | 8 |

| Air fryer 3 Basket 3L 1400W | 25 | 17 | 14 | 8 |

| Air fryer 4 Basket 4.1L 1400W | 20 | 13 | 10 | 8 |

| Air fryer 5 Toaster Oven 11L 1800W | 20 | 13 | 12 | 9 |

| Air fryer 6 Paddle 1.7Kg 1500W | 17 | 13 | 13 | 9 |

| Air fryer 7 Basket 4.2L 1400W | 17 | 13 | 11 | 8 |

| Air fryer 8 Halogen 10.6L 1300W | 23 | 16 | 12 | 9 |

| Air fryer 9 Basket 2L 800W | 24 | 17 | 17 | 10 |

| Air fryer 10 Basket 4L 1400W | 18 | 14 | 11 | 8 |

Table 2: Extract from table 1; time taken to achieve minimum safe cooking

Taking the frozen burger trials as an example of a product supplied by a client for instruction trials, results from table 2 above could be expressed as:

- 1400W air fryers at a calibrated 180°C

- Best 17 minutes, worst 25 minutes.

- All air fryers tested at calibrated 180°C

- Best 17 minutes, worst 25 minutes.

Whilst it might be tempting in the above example to suggest a cook time of 25 minutes, the variability found with testing just the 10 air fryers included in this study means there would be little confidence that this cook time would safely heat the product in all air fryers found in the marketplace. We should also consider that the air fryers tested in the above example were calibrated at 180°C. Based on the dial accuracy performance seen for several of the models tested here, we could expect greater variability in cook times if dial settings had been used.

How Campden BRI can help

Finding a solution

While we are offering a range of air fryer instruction services (see below), we also plan to work with our members to expand the air fryer study, with the ultimate goal of enabling the industry to produce safe, validated, BRCGS-compliant cooking instructions for air fryers. There are a number of ways we may achieve this and will work with our members to determine the best option.

- One option would be to develop an air fryer rating system, like used for microwaves, which would enable effective cooking instruction verification.

- We may also perform further research using a wider range of disparate air fryers and foods to better understand the differences in air fryer performance and the associated risks with on-pack cooking instructions, for higher and lower risk products.

- We can help retailers and suppliers with information to develop a website for cooking instructions in different air fryers (for example, the models sold by the retailer of the food product), so that consumers can look for instructions for their specific air fryer.

Services we offer for air fryer cooking instructions

- We can offer expert advice on air fryer cooking instructions, as well as in depth air fryer testing. Robust scientific rigour is particularly crucial for ready-to-cook products and our service is gold standard for providing this.

- Consultancy and support on how to approach air fryer cooking instruction development and BRCGS compliance.

- Recommendations (generation or verification) for air fryer cooking instructions can be performed using a laboratory procedure which considers the performance of the ten disparate air fryers used in this study. The recommended instruction is not guaranteed to be suitable for every possible air fryer design available on the market (it is important the possible performance variability between air fryers is understood).

- Bespoke validation / verification services for a specific air fryer model, or selection thereof.

If you need support in navigating this topic, or are interesting in working with us on developing an industry-wide solution, then please get in touch.

About Greg Hooper

Greg has worked here at Campden BRI since 1990, after studying Applied Science (Physics and Chemistry). As part of his extensive knowledge and experience in thermal processing and microwave cooking, he was instrumental in setting up the microwave heating category rating system used in the UK, and has travelled internationally assisting and advising on the safe development of microwave products and rating systems.

How can we help you?

If you’d like to find out more about the technical challenges around air fryers, contact our support team to find out how we can help.

Air fryers - ensuring safety and quality

Our technical teams have extensive experience in supporting clients and members to understand the advantages and disadvantages that exist around popular technologies such as air fryers.