Save time, money and transform your thermal processing with ThermaGen

20 May 2025 | David Whittaker, Process Innovation Lead

Campden BRI are excited to announce the launch of ThermaGen™, an online application offering predictive calculation capability for those working with the industrial thermal processing of food and beverage products.

ThermaGen™ - The next generation of thermal processing software

Save time and money with ThermaGen™ a cloud-based application providing predictive calculation capability for those working with industrial thermal processing of food and beverage products.

Billed as the next generation of thermal processing, ThermaGen™, with its simplistic and clean design utilises the finite difference numerical method to provide essential predictive modelling capabilities and deliver a wide array of benefits including:

- Huge time and cost saving in development trials – with the ability to explore multiple different cycle/process options during product development, and compare the implications on food safety risk, operational efficiency, energy use

- Validation time and cost savings plus additional due diligence – as it is supportive of practical validation work by exploring “what-if” scenarios and supporting conclusions based on calculation methods such as General Method or Ball

- Save on the time/cost of possible simulation trials, with robust justification for use of affected batches – as it enables you to quickly understand the disposition of a product batch after a process deviation

- Saves on wasted time of trials and can highlight possible issues at an earlier stage of project – as it can verify the suitability of changes or product or process conditions. For example, new process equipment, or amended process parameters.

So, who is ThermaGen™ most suitable for?

ThermaGen™ can provide amazing benefits for any business involved in the thermal processing of food and beverage products, using batch or in-container processing methods (retorts, pasteurisers, ovens).

ThermaGens accurate predictive modelling capability can also help users explore “what if” scenarios without having to run costly trials.

Why use ThermaGen™?

The use of ThermaGen™ is essential to supporting thermal processing work. In particular, it can add huge value to activities such as establishing new processes, process validation and/or optimisation, or dealing with deviations. Its accurate predictive modelling capability can also help users explore “what if” scenarios without having to run costly trials.

ThermaGen™’s simple cloud-based interface and logical flow means that you do not have to be an expert to experience the huge benefits of thermal process modelling.

In addition, even those currently using an alternative finite difference software package would benefit enormously by swapping to ThermaGen™, as it has been completely built from the bottom up, with new code and a totally new user interface that enables.

- Flexibility in how the product heating rate is generated without the need for manual plotting

- Simultaneous upload of multiple data sets

- New intuitive process flow with clear, user-friendly interface

- A fully supported cloud-based application - no need for software installation (or dongles!)

- Basic and advanced cycle manipulation options

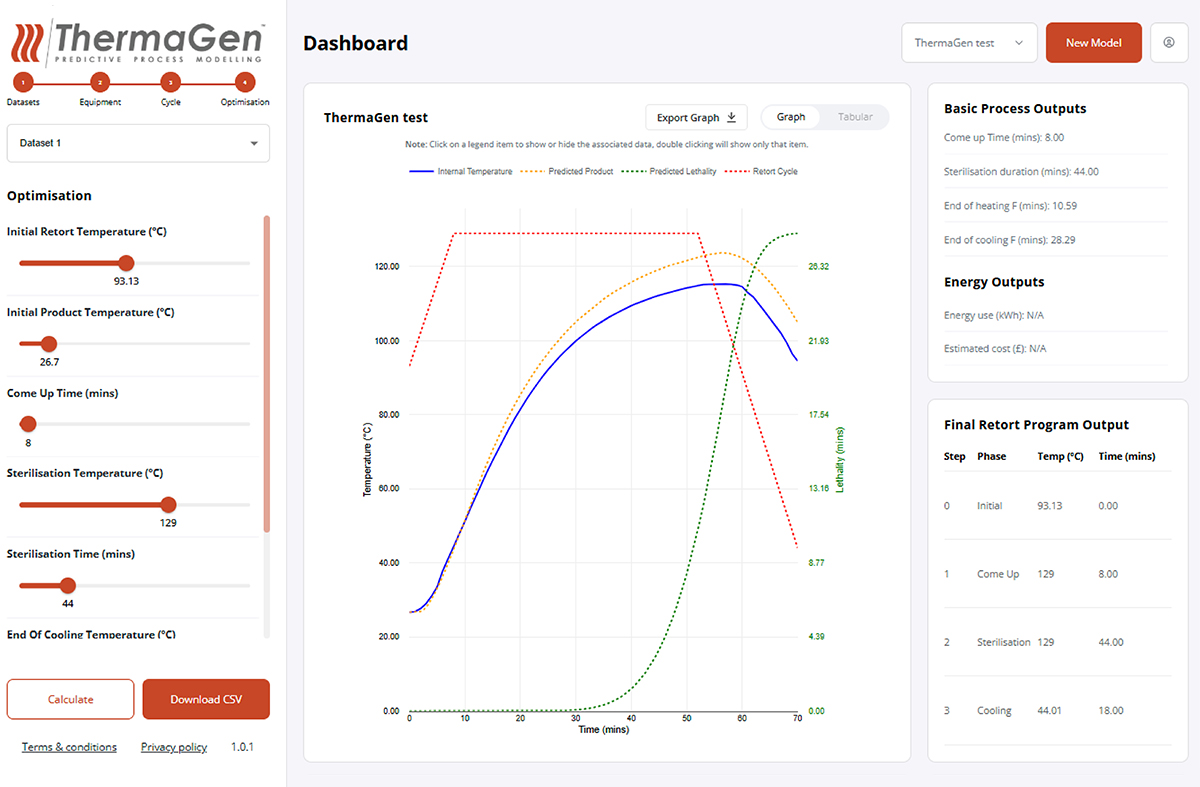

- Process optimisation page, allowing tweaks to process to be made using slider bars with instant calculated outputs

- Product consistently improved and updated over time at no additional cost

How does ThermaGen™ work?

ThermaGen™ requires just a simple data upload (heat penetration data), before displaying a predicted product heating curve that is calculated through the finite difference method.

From there the user can input changes to process parameters, either simple or complex, and ThermaGen™ will calculate the effect of these process changes on the product heating curve with the subsequent microbiological lethality (e.g. F0 value), and estimated energy use.

It outputs this in graphical form, while providing the key calculated values. The results can be downloaded to a spreadsheet, or the graph exported as an image.

For more information about how this process modelling software works, and how it can benefit your business, why not visit our ThermaGen™ product page.

About David Whittaker

David is a thermal and non-thermal processing specialist and has expertise across many food and beverage sectors.

David also delivers many thermal processing training courses and has a real passion for communication in this area, having spoken at several conferences and seminars on the topic, as well as contributing to Campden BRI guidelines.

ThermaGen™ demo

Contact us for a free live video demonstration of ThermaGen™ from a Campden BRI specialist

Thermal processing services

Campden BRI offers professional support to ensure your thermal processes consistently produce safe products.