Measuring food texture

To discuss your needs

Food texture is an important sensory attribute as it affects the way food tastes and how it feels in the mouth. The texture depends on the rheological properties of the food. Measuring food texture involves testing and evaluating the response of a food when it is subjected to forces such as cutting, shearing, chewing, compressing or stretching.

TA-XT2 texture analyser

Several texture analysis procedures are available, depending on the nature of the product, including penetrometry, cutting tests and three point bend tests. Simultaneous measurement of sound (using an acoustic envelope detector) is possible. This is helpful for characterising crispiness. We also offer development of bespoke texture tests.

Key services

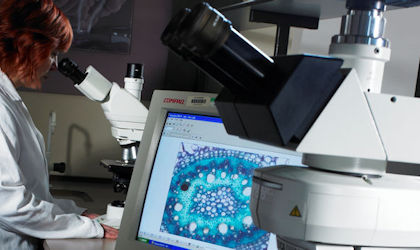

Packaging down the microscope

Microscopy use a range of techniques to examine packaging materials including plastic and metal.

Structure and physical properties

Methods for objective characterisation of food structure and physical properties.

Foreign body identification scheme

Run independently from our own foreign body laboratory, the FOBS scheme enables other laboratories to check their competence in the identification of foreign bodies.

Cereals and milling services

Cereals and milling testing services information, pricing and submission.

Meat, poultry and seafood analysis

Analysis supporting meat, poultry and seafood suppliers, manufacturers and retailers.

Analysis training courses

Explore our analysis related courses including; Calculating meat content and Thermal processing – quality optimisation

Are you getting the most from your Membership?

Watch our membership FAQ videos and find out more about Member Service Account spending, Member Interest Groups, help and advice

Where we refer to UKAS Accreditation

The Campden BRI group companies listed below are accredited in accordance with the recognised International Standard ISO/IEC 17025:2017 by the United Kingdom Accreditation Service (UKAS). The accreditation demonstrates technical competence for a defined scope of methods, specific to each site, as detailed in the schedules of accreditation bearing the testing laboratory number. The schedules may be revised from time to time and reissued by UKAS. The most recent issue of the schedules are available from the UKAS website www.ukas.com. Campden BRI (Chipping Campden) Limited is a UKAS accredited testing laboratory No. 1079