Nutrition, diet and health – challenges faced by the bakery sector

By Gary Tucker and Mike Adams - 24 October 2019

There are many challenges to improving the nutritional profile of our diets, including reduction in the fat, salt and sugar content of food products together with enhancement of fibre and micronutrients. This is highly relevant to the bakery sector because of the functionality of each of these materials within bakery products, as well as the fact that in many countries, bakery and cereal based products are staple foods. The following examples highlight how important these ingredients are to product structure, eating quality and to shelf-life.

- Fat is used between dough layers of a croissant so that the layers separate as a result of the steam generated during baking. This creates a light and crispy texture.

- Salt influences the development of gluten during dough mixing. Reducing salt causes bread dough to become stickier and more difficult to process. This can lead to increased waste.

- Sugar reduces the water activity of cakes. This increases the time it takes for microorganisms such as mould to grow over the shelf life. Reducing sugar will reduce shelf life.

These are selected examples taken from a wide range of functions that fat, salt and sugar perform. In addition to the positive impact that these nutrients have on product quality, a number of important macro- and micronutrients have a potentially negative impact on product quality. The following examples highlight some of these.

- The use of fibre in bread, most commonly in the form of wheat bran, causes significant impacts on the texture, taste and appearance of bread, as well as significantly impacting the manufacturing process and shelf-life

- The addition of bioavailable forms of many micronutrients, such as the use of non-elemental iron (elemental iron is used as a fortification in white flour within the UK milling industry) can have a negative impact on flavour and appearance of breads

- The use of protein in products such as biscuits, to improve the protein content of consumers diets, can have negative impacts on areas such as taste, texture and acrylamide level.

This article outlines some of the major challenges the bakery sector is facing in making its products healthier.

Fat reduction

Government initiatives to reduce the total fat content of foods are based on both calorie reduction,

since fat is a calorie dense nutrient, and also on the removal of certain fat fractions from our diet,

notably trans and saturated fatty acids. Hard fats have been used in bakery products for centuries.

Traditionally these have been animal-based fats, such as suet and butter, but are now more commonly sourced

from tropical seeds, such as palm, shea and coconut. They have many functional properties of benefit to

product quality. In recent years, the bakery sector has worked hard to achieve reductions in fat,

particularly hard fat, both for health reasons, and the case of palm, sustainability and ethical reasons.

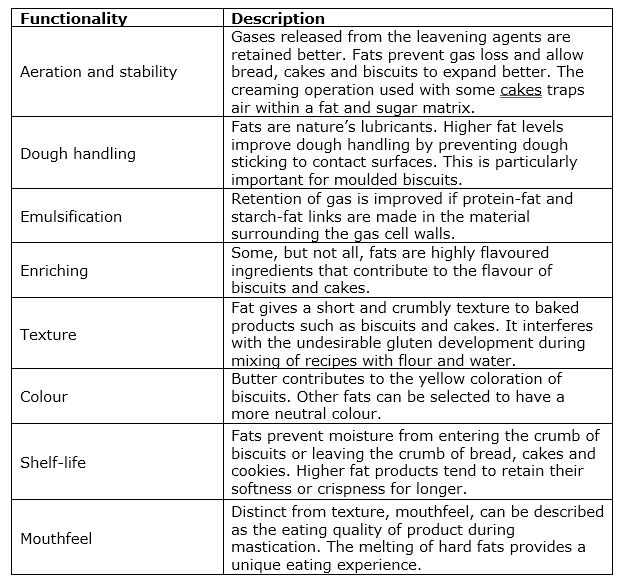

Fat not only contributes to the eating qualities of biscuits and cakes, it also plays a functional role in dough handling and baking. Since fat has a range of technical roles, it is important to ensure that these roles are still met in reduced fat products or in those containing a replacement material. Table 1 outlines some of the functional properties of fats in biscuits that will need to be addressed to avoid a loss in quality.

Table 1: Main functional properties of fats in bakery products

The key role of fat in biscuit dough has been described as shortening, which gives biscuits their characteristic ‘melt in the mouth’ crumbly texture. The mechanism by which fat contributes this property to biscuits is by coating flour particles during mixing of the biscuit dough. This fat coating prevents gluten from absorbing water during mixing and becoming elastic and extensible. Gluten development is essential in bread dough but is undesirable in biscuit dough because it produces tough and chewy biscuits.

A secondary role of fat is to coat any air bubbles present in order to enhance their stability during baking. This role is similar to the stabilising effects that fats have on bubbles in bread dough and cake batter which prevent the bubbles rupturing and coalescing.

While both liquid and solid fat can be used to coat wheat particles to restrict gluten development, the firmness, and therefore the machinability of dough, is directly related to the solid fat index (SFI) of the dough fat. Short doughs that contain liquid oil at the point of handling are difficult to machine resulting in irregular shapes. The ability to coat bubbles to retain integrity during dough handling and baking is also best found in a fat with a developed crystalline structure rather than in liquid oil. Hard fats, rather than oils, are used to provide the required functionality in biscuit dough, with the naturally produced ingredients of choice being either palm oil, which has a melting point of about 36°C, or butter, which melts at 32-35°C. The use of saturated fats is therefore central to biscuit technology.

Sugar reduction

Sugar has received negative publicity recently because of its impacts on our health. It has taken over

from fat and salt as the ingredient that the food industry needs to reduce. There are three main health

issues related to excessive sugar consumption:

- Diabetes: glucose (sugar) levels in the blood become high because the body is unable to convert excessive sugar to energy or store it. Type 2 diabetes is linked with obesity

- Obesity: this decreases satiety, with excess food converted to fat

- Dental: sugars feed tooth decay bacteria and cause dental caries

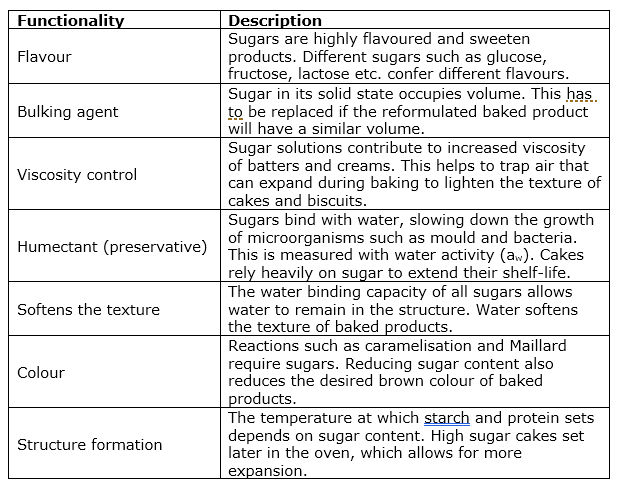

Sugar is a key ingredient affecting many properties of baked products (Table 2). When replacing sugar, some of these technical functions must be mimicked to produce a product which is palatable, functional and appealing. This usually requires more than one ingredient to be added, which increases cost. Sugar is one of the least expensive and readily available ingredients compared with other bakery ingredients such as flour, egg and fat. Sugar replacement usually comes at a cost and more ingredients must be declared on the label.

Table 2: Main functional properties of sugar in bakery products

Campden BRI has investigated the impact of replacing sugar in most types of baked products. The soluble fibre inulin is one of the most popular alternatives because it contains fewer calories than sugar. Inulin is a non-digestible oligosaccharide found in many plants such as chicory root, banana and plantain. It has approximately 10% the sweetness of sugar, and behaves as a bulking agent, contributing to the body and mouthfeel of the product. Up to 20% sugar in cakes was replaced with inulin and had a comparable specific volume to the control cake. The water activity of 0.84 gave a predicted mould-free shelf-life of 13 days at 25°C.

Fibre increase

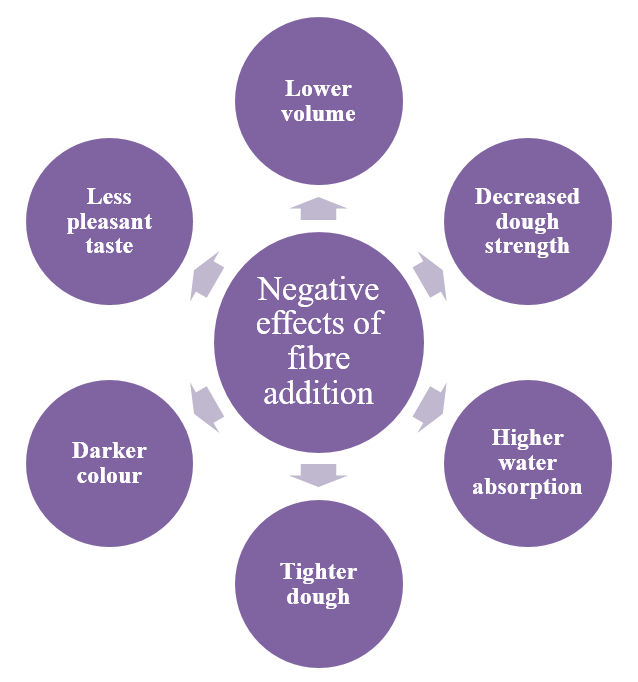

Despite the health benefits associated with increased fibre in bread and baked products, there are

challenges because of the negative effects on quality. There are several technical issues (Figure 1) that

must be overcome.

Figure 1. Negative effect of wheat bran on wheat bread quality

Campden BRI carried out a study with the aim of understanding these issues. Key to this was a clear understanding of the impact of bran components on water absorption by the dough and gas cell stability in sandwich bread. It is well documented that addition of fibre increases the water required to make processable dough.

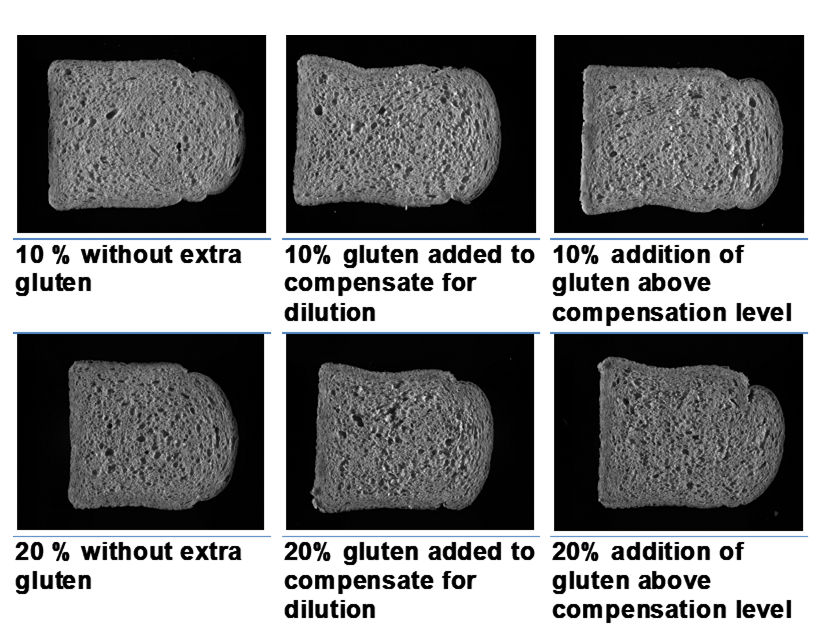

The focus of the work carried out by Campden BRI was on wheat and oat bran, which are both readily available in the UK bakery industry. As expected, adding these fibres decreased the bread’s specific volume. There was a greater reduction in volume at the higher (20%) substitution level compared to the lower (10%). Extra vital wheat gluten was added (Figure 2) to compensate for the dilution of gluten with bran with the aim of increasing bread volume. No significant difference was found in bread volume with added gluten, however, it did impact on crumb structure as the cell wall thickness and diameter both increased suggesting problems with bubble coalescence and gas retention.

Figure 2. Comparison of wheat bran bread C-Cell pictures

Micronutrient Increase

Recent research has shown that in the UK, a significant portion of the population is under consuming

vital micronutrients, such as vitamin D, as well as iron, folate and calcium. Whilst some bakery

ingredients and products are fortified with micronutrients, evidence suggests that the bioavailability of

these, such as elemental iron added to UK flour is poor. Whilst more bioavailable forms of nutrients are

available for use, they often have very variable bioavailabilty, depending upon the matrix that they are

added in. Careful consideration is required to ensure suitable fortificants are used.

Campden BRI is currently undertaking a three-year research programme to improve the nutritional status of common bakery raw materials, and their end products. Part of the study focuses on the potential to use natural processes, such as sprouting, to improve micronutrient content and bioavailability in staple foods. Hopefully this will assist the industry in helping tackle a global public health issue.

Conclusion

Evidence linking diets high in fat and sugar to a range of growing health issues such as obesity and

diabetes has led health campaigners and governments to call for the level of fat and sugar to be reduced

in common products. Bakery products are being targeted because they are high in both, particularly sugar. In

comparison, fibre has a reputation of being a healthy ingredient thanks to health claims associated with it.

Fibre compounds differ in terms of both nutritional and technological functionality. This makes it possible

to gain technological benefits, for example sugar replacement in certain products, by choosing an

appropriate type of fibre. Micronutrient deficiency is an issue across the globe. Staple bakery products are

a suitable vehicle to try and increase the levels of important, under-consumed nutrients, such as iron.

This article was previously published in European Baker and Biscuit.

Contact: Support Team

+44(0)1386 842291

support@campdenbri.co.uk