ThermaGen™: Save time, money and transform your thermal processing

Are you weighed down by costly trial runs, or struggling to make accurate predictions with the thermal processing of your food or beverage products?

Help is at hand with the launch of ThermaGen™, our next generation cloud-based thermal processing tool, offering essential predictive modelling capabilities and the ability to deliver a whole host of benefits, including:

- Huge time and cost saving in development trials

- Validation time and cost savings plus additional due diligence

- Savings on the time/cost of possible simulation trials, with robust justification for use of affected batches

- Less time wasted on trials as it can highlight potential issues at an earlier stage of a project

Take advantage of a limited number of early bird discounted member licences, enjoy a 20% member discount starting from £1,700+VAT (per user), Non-member price starting from £2,115+VAT (per user).

For more information read our blog: ThermaGen, an introduction to the next generation of thermal processing or contact us to arrange a demo.

Fully supported cloud application

Intuitive process flow and user interface

Basic and advanced manipulation cycles

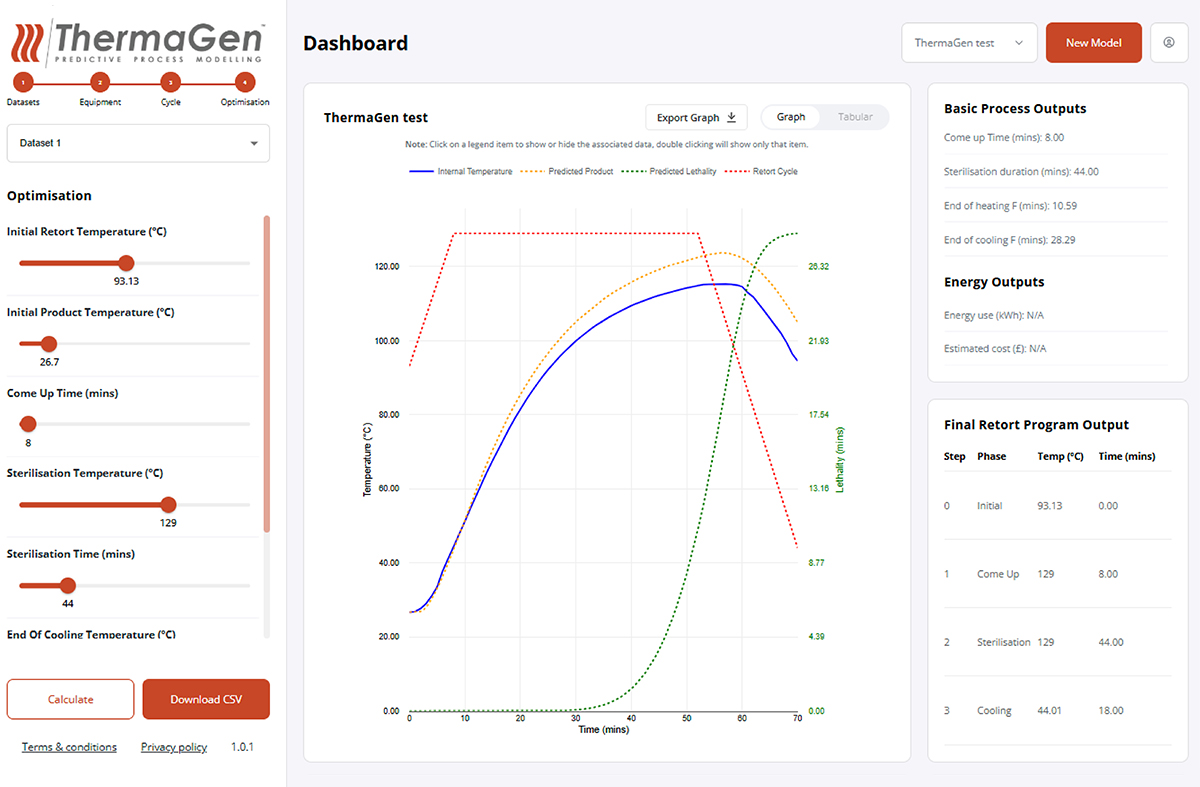

Slide bars for faster calculated outputs

Who benefits from using ThermaGen™?

Built for any business involved in the thermal processing of food and beverage products, ThermaGen™ offers amazing benefits for those using batch and/or in-container heat processing methods (retorts, pasteurisers and ovens).

With its simple and clean design, it takes no time at all to get comfortable with this powerful tool and utilise everything available at your fingertips.

The benefits of ThermaGen™ are extensive:

- Explore multiple different cycle/process options during product development, and compare the implications on food safety risk, operational efficiency, energy use.

- Support practical validation work by exploring “what-if” scenarios and supporting conclusions based on calculation methods such as General Method or Ball.

- Quickly understand the disposition of a product batch after a process deviation.

- Verify the suitability of changes or product or process conditions. For example, new process equipment, or amended process parameters.

How does ThermaGen™ work?

Requiring just a simple data upload (heat penetration data), ThermaGen™ can quickly calculate through the finite difference method and then display a predicted product heating curve.

From there the user can input changes to process parameters, either simple or complex, and ThermaGen™ will calculate the effect of these process changes on the product heating curve with the subsequent microbiological lethality (e.g. F0 value), and estimated energy use.

Contact us for a demo

Our team can provide:

- A live video demonstration of ThermaGen™ from a Campden BRI specialist

- Log-in credentials for a free trial

- More information about ThermaGen™ features and how to use them

- Details on pricing (favourable rates for members)

- Answers to any technical or commercial questions