3D printing of food

By Craig Leadley - February 2020

Introduction

3D printing is a rapidly growing technology that is already in widespread use for customised, small-scale manufacturing of engineering components for various industries including the aircraft, automobile and biomedical sectors. It is also referred to as “additive manufacturing” as it is based on layer-by-layer deposition of material using computer-aided design. In recent years, the food industry has shown an increased interest in the technology for food applications due to its potential for the creation of unique shapes and the late customisation of food, as well as personalised nutrition and food waste revalorisation. New 3D printers are now commercially available for a range of food product types. These include dry powders like sugar, cocoa powder or dry biscuit mixes, and paste-like materials such as chocolate, vegetable purees, doughs or pancake batters. The application of the technology to food is, however, not without challenges.The process of 3D printing is, at least in theory, simple. The first step is to digitally design a 3D object that will be printed with food. The second step is the creation of a printing file by “slicing” the digital 3D object and coding the movements of the printhead for each layer with dedicated software. The printing file is eventually uploaded onto the 3D food printer that will print or set each layer of food sequentially in three dimensions. In practice, a range of 3D food printing technologies are available. Powder-based materials can be printed using techniques such as selective sintering or binder jetting. Selective sintering is based on the deposition of a layer of powder followed by a superficial melting of the material to allow its adhesion to the subsequent layer. It can be achieved using a laser or a source of hot air. With binder jetting, the layers of powder are bound to each other by the deposition of an intermediary liquid binder. Paste-like foods can be printed by stereolithography apparatus, which consists of melting of the material between layers (as referred to with selective sintering of powders). Droplets of food can be also deposited using inkjet printing to build a food structure in 3D. Fused deposition modelling (FDM) and hydrogel-forming extrusion both involve the deposition of a continuous stream of food paste for each layer. The difference between them is that fused deposition modelling relies on the self-supporting properties of the paste on a print bed while hydrogel-forming extrusion requires the deposition of a paste containing hydrocolloids into a gel setting bath. Fused Deposition Modelling is probably the most widely used method for food printing. A broad range of materials can be printed using FDM – see Figure 1 for examples we’ve printed at Campden BRI.

Figure 1. FDM printed materials. Left to right: ground beef, pea puree, milk chocolate, butter icing, carrot puree, carrot and pea puree, biscuit dough

The importance of rheology

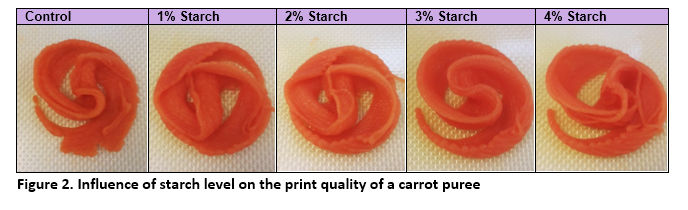

The rheological properties of a food are critical parameters that need to be understood in order to successfully print using FDM. There is frequently a balance to be struck: the food product needs to flow smoothly when extruded from the print head (without blocking or trailing) but also needs to have sufficient structure, post deposition, to support the subsequent layers of deposited material. The addition of functional ingredients such as starches and gums can help or hinder the quality of print. Figure 2 shows, as an example, the impact of starch addition on the print quality of a carrot puree. In this example a carrot puree containing 3% starch produced a better quality of printed product compared with the other formulations.

Figure 2. Influence of starch level on the print quality of a carrot puree By modelling the shear rates that occurred during extrusion and measuring the rheological properties of the material at these shear rates, it was possible to predict the print quality of the carrot puree. Print quality could be predicted as a function of printer settings (extrusion rate and printing speed) and rheological properties (consistency index, flow index and yield stress).

Personalised nutrition

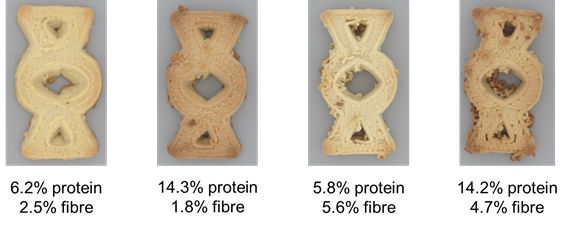

The ability to manufacture personalised and late customised products using 3D printing is an attractive proposition. In theory, an end user could order a specific nutritional profile that could be printed on demand e.g. “I want a high fibre, high protein product fortified with a specific vitamin”. While attractive in principle, our recent work has demonstrated that this might be more challenging in practice. For instance, we attempted to print and bake a high protein, high fibre biscuit by customising the recipe with varying levels of pea protein and pea fibre. The fortifying ingredients impacted on the rheological properties of the dough which affected print quality (Figure 3). As fibre content increased, print quality reduced. High protein formulations resulted in darker biscuits (baking times and temperatures were standardised in our experiments). None of these issues are insurmountable but this simple experiment demonstrates that formulation modification impacts on rheology and consequently print quality. Downstream processing (i.e. operations post printing such as baking and frying) is also impacted by formulation. The ‘click and print’ dream is not a simple as might first appear. As the technology develops, it may be that methods such as artificial intelligence (AI) could be used to modify print settings and downstream processing ‘on the fly’ to deal with this product/process interaction.

Figure 3. Customised/personalised nutrition is attractive in principle but more complex in practice

Consumers’ attitude towards 3D printed food

Providing that 3D food printing is technically possible and commercially viable, consumer acceptance of 3D printed food is critical if it is ever to see widespread commercial implementation. If consumers reject the technology, then technical feasibility is irrelevant. A panel of 215 consumers was recruited to assess consumer awareness of the technology, their willingness to consume and buy 3D printed food, and interest in 3D printing food at home. Only a third of the respondents (36%) had heard about 3D printed foods, but a third of the respondents who were aware of 3D printed foods (33%) thought they could not explain what it is. These results highlight a lack of communication to the consumers that would need to be mitigated to increase the potential future sales of 3D printed foods. After being shown a definition and pictures of 3D printed foods, most respondents (83%) would consider eating 3D printed food. The principal reason mentioned by respondents considering eating 3D printed food was the novelty of such foods (75%). The new sensory experience (51%), appealing/creative shapes (47%), late customisation (44%) and food waste reduction potential (43%) were other reasons chosen by around half of the respondents. In contrast, the principal reason cited by the respondents rejecting 3D printed foods was the perception that the product would have undergone a high level of processing (67%). Additional concerns included the likely presence of artificial ingredients (50%), poor texture (50%), bland taste (47%) and safety concerns (42%). The 3D printed foods that receptive respondents would consider eating the most were sweet products (78%) including biscuits, chocolate, sweets, cake decorations and cakes, while they showed less interest for 3D printed ready meals and meat products (56% and 53% respectively). When asked about buying 3D printed foods, the majority of respondents (59%) found the idea either somewhat (44%) or very (15%) appealing.

Attitudinal differences were investigated between genders and age groups based on the respondents’ answers and characteristics. Males showed a more positive attitude towards 3D printed food than females, as a higher proportion of males would consider eating 3D printed food (92% for males vs 80% for females). Interestingly, male respondents were more likely to buy 3D printed meat products than females, whereas more female respondents found the idea of buying 3D printed cake decorations appealing. In terms of opinions by age, two groups were evaluated: younger respondents (18-39 years old) and older respondents (40-69 years old). A significantly higher proportion of younger respondents found the ideas of buying 3D printed food and printing food at home appealing (69% and 74% respectively) compared with the older respondents (52% and 58%respectively).

Conclusions/ future perspectives

3D printing of foods is already in commercial use. Generally speaking, it is being used for relatively low volume, novelty applications like customised chocolate, cake decorations or for use in high end restaurants to create a unique dining experience. It is without question that intricate and impressive designs can be printed that would be difficult to reproduce with conventional technologies. A major limitation of current approaches is speed of printing which can be of the order of 5-15 minutes depending on the complexity of the design. Some form of multi-head or serial printing designs are needed before high-speed, industrial 3D food printing looks feasible from the perspective of throughput and cost.

Existing printers are, generally, adaptations from non-food designs rather than being created with food printing in mind. There are, therefore, hygienic design and materials of construction issues that need to be overcome. Collaborative work between food industry end users and equipment suppliers is needed in order to address this.

The principle of late customisation is very attractive but as demonstrated previously, it is not simply a matter of ‘click and print’ because flow behaviour and downstream processing after printing are impacted by formulation. While it may seem to be entering the realms of science fiction; as Industry 4.0 is adopted in the food industry, it is not inconceivable to think that customised orders could be received via on-line orders and printed in real time. For the potential of this late customisation approach to be realised however, process lines that can ‘adapt’ to changing formulation need to be available. Technologies like AI will be a key enabler for this approach. Clearly there will be practical limitations – to take the biscuit example discussed previously, whilst it may be possible to adjust printer settings ‘on the fly’ to account for changes in flow behaviour due to formulation, it would not be feasible to change baking temperature and time on a per biscuit basis!

Consumer acceptance of the technology does not appear to be a barrier to adoption though it is fair to say that consumer awareness of the approach appears to be quite low. Aside from industrial high-volume manufacturing or food-service applications, it may be that 3D food printing finds a niche for in-the-home applications where the current speed of printing may not be so problematic.

The findings in this article are from a member-funded research project that finished in 2019. Campden BRI members can access the R&D report that was produced after this projected ended here.

Craig Leadley

+44(0)1386 84842059

craig.leadley@campdenbri.co.uk