Maximise your chances of a successful product launch

By Charlotte Holmes- 6 December 2017

The trade press and market research reports are filled with sobering statistics about new food and drink products failure rates, but this doesn’t tell the whole story. Many new products don’t even make it to launch - they fail quietly in companies’ NPD kitchens or during factory trials, causing significant losses in time and money. So why does this happen?

Product innovation

We have decades of experience of transforming ideas into real food and drink products. The problem we see time and time again is companies don’t consider all the factors that will affect their product right at the start. They often overlook crucial legal, safety, quality, processing or packaging factors. For example, the client has specified a minimally processed product in the brief but have to do a u-turn during the feasibility stages so that they can satisfy due diligence requirements and demonstrate that the product is safe. The client then ends up with a highly processed product which they didn’t want, which doesn’t have the desired taste or texture and doesn’t meet the brief. The only option is to repeat the development work that has already been done at this later stage of the project which can be costly and delays the product launch.

Save yourself time, money, resources and get your product on the shelf quicker

You can maximise your chances of a successful product launch by considering all aspects of development at the start of the process. This will save you time, money, resources and get your product on the shelf quicker.

Some important things to consider when writing you product brief include:

- Understand your target market/consumer - is there a market for the product? Would the consumer buy this product? How well does it meet their needs? How much might people expect to pay for it?

- Feasibility of product - can it be produced economically (i.e. for less than the expected market value)? Is there a need for long-term technical development? Is capital spend required? If so, what is the expected pay back time? Does your company have a suitable sales and distribution network for the product type?

- Shelf life – consider the closed and open shelf life that is achievable and identify the factors that limit both. The product formulation, packaging and processing should only be designed after you have considered the factors that may limit the product’s shelf life from a microbiological, nutritional and quality perspective.

- Processing - consider your production environment capabilities or those of your contract manufacturer.

- Hygienic design - getting the design right at the start will prevent issues from arising later in production and help to increase efficiency. You also need to also consider the production environment capabilities of your company or of your contract manufacturer.

- Regulatory requirements – when writing the brief you need to consider what nutrition/health claims, use of ingredients/additives and labelling information is legally allowed, what is achievable and what is suitable for the product.

- Packaging – choose a suitable package that takes into account how the product will be processed and how it will be handled by the consumer. Does it meet the company’s sustainability policy? Does it deliver the right pack size to the consumer?

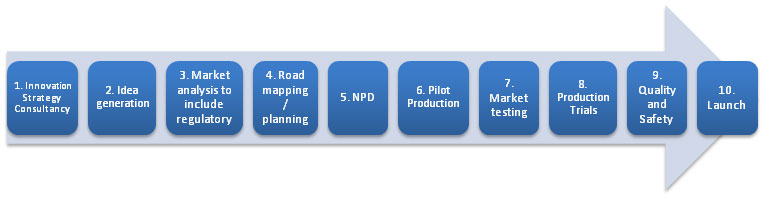

Success requires skills from a team of individuals with different expertise and the use of a stage gated process.

Developing new products is complex and full of many hurdles and risks. The wrong thermal process, a problem with an ingredient or microbiological issues can impact on a product’s safety and quality. NPD requires a holistic approach with specialist knowledge and expertise from a wide range of areas, including ingredients, safety assurance, thermal process validation, legislation and packaging. Unless you have your own product development team, you will probably need the help of food science and technology experts. If you involve us at the start of your process before you’ve started development work, we can help take your blue sky idea and develop it into a finished product that works on a commercial scale.

To find out how we can help you please get in touch.