Solid-state microwaves – the future?

By Danny Bayliss and Greg Hooper - 22 October 2019

The introduction of microwave heating food in the 1940s sparked a revolution in the way we process foods both commercially and domestically.

The industry has found many ways to apply this technology with processes that include raw meat cooking and ready meal sterilisation. It continues to develop methods to this day with new technologies such as continuous flow microwave processing. However, around 70 years on, while they may be almost ubiquitous, it is evident that traditional magnetron microwaves still have some issues.

What are the issues with traditional microwaves?

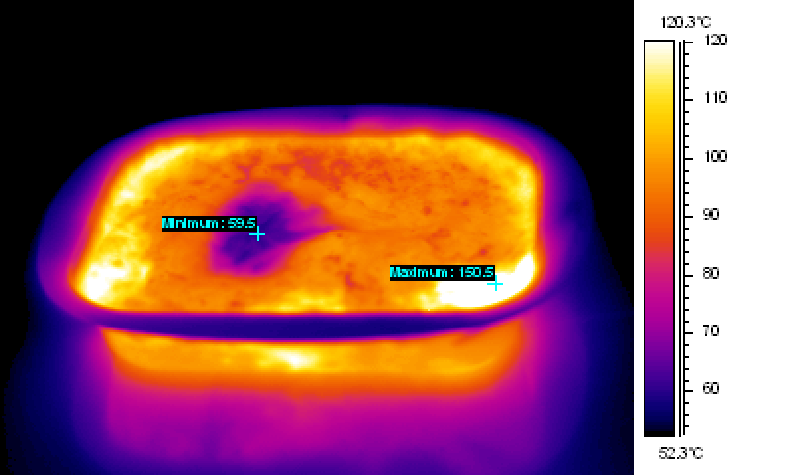

Traditional magnetron microwave ovens remain one of the few technologies that have experienced little change since they were first invented. The convenience of this technology for heating food is unparalleled. Although, with a ‘fixed’ frequency and (usually) only one energy source (magnetron), traditional microwaves can cause non-uniform heating of foods, creating hot and cold spots in a product which can impact food product quality (Figure 1).

Figure 1: The lack of uniformity in heating this ready meal is apparent with a cold spot (surface temperature in this case) of approximately 60°C and a corner temperature of over 150°C.

But just how limiting can a ‘fixed’ frequency be when heating food? A fixed frequency means a fixed wavelength (frequency and wavelength are related). Simply put, when a single source of microwave energy of a fixed wavelength enters the oven cavity, it can ‘bounce around’ and be reflected off the walls. This then forms a ‘fixed’ pattern of microwave energy inside the cavity with some areas of higher energy and some areas of lower energy. The result? Hot and cold spots in foods. If there are multiple sources of microwave energy and/or if the frequency (and thus wavelength) are changing, then the microwave (field) pattern inside the cavity can vary, meaning more even heating. With these points in mind, it is easy to see how specific areas of a food could be ‘neglected’ during heating with a traditional magnetron microwave and thus remain colder than other parts. Or conversely, how some areas could be over-heated from excess exposure to the microwave energy.

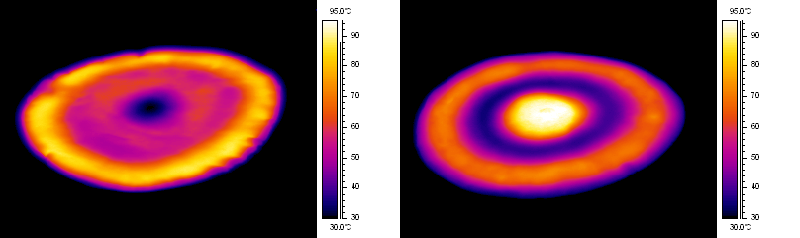

Figure 2 shows how these variances in heating uniformity can differ even between microwaves of similar power output.

Figure 2: A visual representation of how different heating patterns can cause non-uniform heating. These two images are from separate domestic microwaves with a similar rating (wattage). When heating the same product, they were found to have different heating patterns; the right image showing a hot spot in the centre and the left showing a cold spot in the same place, but with more heating around the edge of the product.

Turntables/stirrers can help to reduce this non-uniformity, but they are not a panacea - some parts of the product can still be over-processed when ensuring that the whole product has received a targeted temperature for a specified hold time (thermal process). The non-uniform temperature distribution raises the issue of food safety with the possibility of microorganisms within the cold spots not being destroyed. This is unless thorough instruction testing has been performed. For example, using several microwave ovens with different heating patterns (as shown in the above images) to test cooking instructions.

An unexpected solution to these problems may well come from a relatively recent development, the advent of smart phones - and subsequently the invention of the solid-state microwave generator.

What are solid-state microwaves?

The rapid developments in the telecommunications sector to accommodate smart phone wireless communications has led to the advance of solid-state semiconductor devices. These devices can generate and amplify radio frequency (RF) signals that the phones use for data transmissions.

However, the solid-state semiconductors can produce variable frequencies, including the microwave frequencies (2.4-5GHz) that we’re interested in. This opens the potential for these devices to also be used for food heating applications.

How could solid-state microwaves overcome the issue of non-uniformity?

Solid-state RF technology has the potential to enable slight changes in the frequency, measure the energy in the cavity for feedback and shift the frequency and phase in ‘real-time’. When heating food this could minimise standing waves and potential hot spots which will improve product quality by heating it more uniformly. It could also reduce the chance of over-processing and the risk of under-processing.

Uniformity may also be improved with multiple energy sources. As mentioned, traditional magnetron microwaves usually only have one energy source, however the multiple microwave generators of solid-state microwaves allow simultaneous heat penetration from several energy sources. From this you can see how exposing a food product to microwaves from multiple sources simultaneously could distribute the microwaves (and subsequent heat) more evenly.

The future of solid-state microwaves

Due to cost implications, solid-state microwaves currently only hold potential in combination ovens. But as the technology develops and the price comes down, it’s possible that these microwaves will challenge or even replace traditional magnetron microwaves. The applications of these solid-state microwaves will then depend solely on our creativity.

So, what’s in it for the food and drink industry?

If this technology can prove itself with more uniform heating than what we see in conventional magnetron microwave ovens, the industry may find itself with a new and revolutionary heating method in its tool box.

More uniform heating will reduce the possibility of over-processing in specific areas of the product which will likely improve overall product quality. Under-processing will also be far more unlikely and will therefore increase the safety of such foods.

Researching the new technology

As part of our research into emerging technologies, we’re exploring the potential benefits of this solid-state microwaves as part of a feasibility study. With the processing kit installed, we’re conducting initial trials on ready rolled pastry and mashed potato to evaluate the heating performance of a solid-state RF cooker. The investigation will determine whether the solid-state microwave can reduce hot and cold spots in a product as it applies the mechanisms discussed above.

The research is part of our member-funded ‘New Technologies for Food and Drink Manufacturing’ project which has been running in various forms since 1990. We compile our findings in a bulletin - free for members

We’re always looking for feedback on technologies to explore or review as part of the information and feasibility trials. Submit your suggestions to newtechnologies@campdenbri.co.uk so we can investigate technologies that interest you.

This blog was originally commissioned as an article for Food Spark

Support Team

+44(0)1386 842291

support@campdenbri.co.uk

Greg Hooper

+44(0)1386 842039

greg.hooper@campdenbri.co.uk

About Greg Hooper

Greg has worked here at Campden BRI since 1990, after studying Applied Science (Physics and Chemistry). As part of his extensive knowledge and experience in thermal processing and microwave cooking, he was instrumental in setting up the microwave heating category rating system used in the UK, and has travelled internationally assisting and advising on the safe development of microwave products and rating systems.