The challenges of reformulating with plant-based proteins

By Mike Adams - 27 November 2020

Demand for plant-based alternatives to animal-origin ingredients in bakery products has grown significantly in recent years. The rise of vegan and plant-based diets has encouraged the food industry to produce or reformulate products to cater for this growing band of consumers. Plant-based proteins are consequently in demand as the industry looks for alternatives to animal-based ingredients. The challenge is the sourcing and extraction of suitable ingredients, especially proteins, that can compete with the current animal-based ingredients that many manufacturers depend on. The main animal-origin ingredients used in bakery products include dairy ingredients, such as butter and milk powder, egg ingredients (either powdered or liquid), honey and gelatine.

The increased popularity of plant-based diets has led to significant advancements in the field of plant-based proteins including the discovery of novel sources and improved protein extraction methods. Our researchers are aiming to develop techniques to produce protein-rich ingredients from plants, optimise their nutritional value, and understand the functionality and technical performance of these ingredients in food products. Find out more about the project here.

Why plant-based re-formulation is so challenging

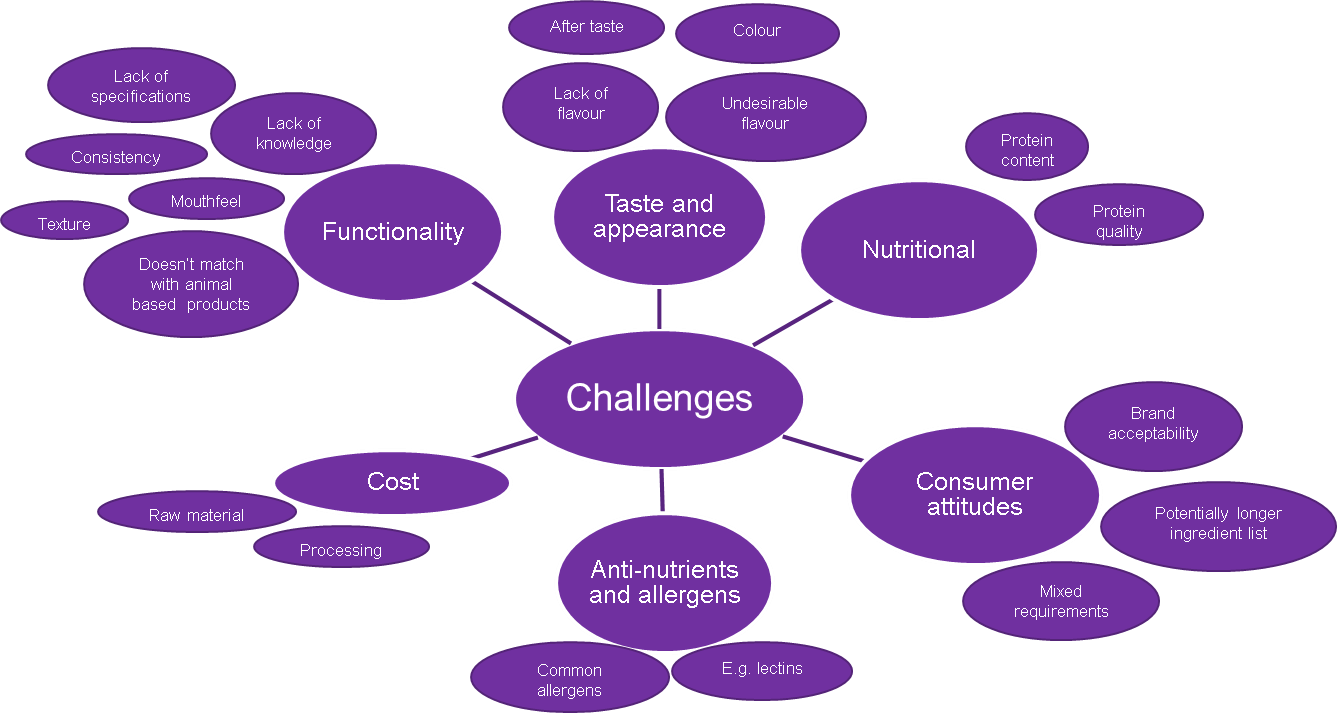

Several food business operators, representing a wide range of different food and drink product manufacturers, were consulted to understand the challenges the industry is facing due to the growing demand for plant-based products and ingredients. The consultation identified a number of technical challenges (Figure 1) that they experienced when delivering a good quality product, without using animal-based ingredients (that are traditionally relied upon by industry). They included:

- nutritional challenges related to protein content, protein quality and protein digestibility

- product development challenges related to ingredient functionality such as change in texture, mouthfeel or consistency of the final product

- the functionality of plant-based ingredients that do not match that of animal-based ingredients

- the lack of knowledge on how to use plant-based ingredients

- the potential change in colour and appearance of the product

- the potentially longer ingredients list that’s required to achieve a similar functionality to the animal-based products

- concerns around how to match the taste and flavour, avoid undesirable flavours and ensure there isn’t a lack of flavours or aftertaste

- higher costs of raw materials and processing

- safety of the ingredients, especially regarding the anti-nutrients found in many plant-based materials and allergens such as soya and lupin

- lack of consumer awareness and the fact that even within the vegan market the requirements can be mixed, and

- a lack of understanding how the changes will impact on the brand acceptability

Reformulating without animal-based ingredients

Egg and dairy ingredients are the main animal-origin ingredients used in bakery products, however, there are many others. Milk powders, high in the reducing sugar lactose, are used to aid browning in short biscuits and pastries; milk fats such as butter are used to provide flavour and a crumbly texture to shortbread biscuits and the stereotypical buttery/creamy flavour to laminated fermented pastries such as croissants. Yogurt offers acidity to naan breads and pancakes, while soft and hard cheeses - used in cheesecakes, savoury biscuits and crackers - provide flavour, batter consistency and texture. Alternatives to dairy fats are almost always palm oil-based, but there are others based on coconut, shea and blends with oil. Butter flavourings can be used in conjunction with margarines and shortenings to deliver the typical buttery notes expected in products such as shortbread and croissants.

For many bakery products, eggs are a vital ingredient. Egg is a unique multi-functional ingredient which is used widely across the food industry in a variety of different products. Egg is used for aeration, emulsification, enriching, colour, shine, and structure forming. No other single ingredient provides this level of functionality. Due to egg’s ability to do so many jobs at once, many bakers all over the world have come to depend on it. Egg-free recipes are still few and far between, and for good reason. The big challenge is to find alternatives that alone, or in combination with others, can replace the functionalities required in bakery products.

Egg yolk is used in the bakery sector to enrich and emulsify as well as provide colour to baked goods through its natural pigment xanthophyll. The yolk is comprised of lipoproteins, such as lecithin, which can be fairly easily replaced with alternative lecithins found in soya or rapeseed. The high-fat content of the yolk (30%) acts to enrich doughs and batters but can be replaced by an increase in recipe fat. The problem really lies in the egg white which, due to its complex protein composition and multi-functionality, is more complicated to replace using singular alternative ingredients.

The white of an egg, the albumen, is used in many applications to provide volume and to set structure due to its capability to easily aerate and then coagulate and set on heating. Cakes, sponges and egg-based fillings (such as mousses, meringue and marshmallows) rely on this functionality in order to achieve their soft texture and volume. The albumin is not a single protein, it is in fact a mixture of different proteins and they all have slightly different technological functionalities (Table 1). In baked products, for example, ovomucin and ovomucoid are mainly responsible for gelling whereas ovoglobulins are mainly responsible for aeration, but they function best together.

|

Protein type |

% in albumen |

Isoelectric point |

Molecular weight (kDa) |

Denaturation temperature (°C) |

|

Ovalbumin |

54.0 |

4.5 |

44.5 |

84.0 |

|

Ovotransferrin |

12.0 |

6.1 |

76.0 |

61.0 |

|

Ovomucoid |

11.0 |

4.1 |

28.0 |

77.0 |

|

Ovomucin |

3.5 |

4.5 |

5500 |

|

|

Lysozyme |

3.4 |

10.7 |

14.3 |

75.0 |

|

Ovoglobulin (G2 and G3) |

4.0 |

5.5 |

30-45 |

92.5 |

It is possible to replicate these functionalities to some extent by using plant-based ingredients which are known to have great functional properties such as foaming, emulsification and gelling. However, plant proteins are not a uniform group of proteins. The traditional way of classifying plant proteins is to group them based on their solubility (Table 2). This is called the Osborne classification method. Albumins are soluble in water, globulins are soluble in saline solutions, prolamins are extractable in concentrated aqueous alcohol solutions and glutelins are extractable in dilute aqueous acid or alkali solutions. The solubility of the proteins is a prerequisite for other functionality properties such as emulsification and foaming.

|

Plant source |

Albumins |

Globulins |

Prolamins |

Glutelins |

|

Wheat |

6-10% |

5-8% |

35-40% |

40% |

|

Rice |

2-6% |

12% |

4% |

80% |

|

Barley |

3-5% |

10-20% |

35-45% |

35-45% |

|

Maize |

4% |

4% |

60% |

26% |

|

Sorghum |

2-7% |

2-10% |

35-60% |

20-35% |

|

Soybean |

90% |

|||

|

Pea |

15-25% |

50-60% |

||

|

Chickpea |

8-12% |

53-60% |

3-7% |

19-25% |

|

Lupin |

25% |

75% |

||

|

Rapeseed |

20% |

60% |

2-5% |

15-20% |

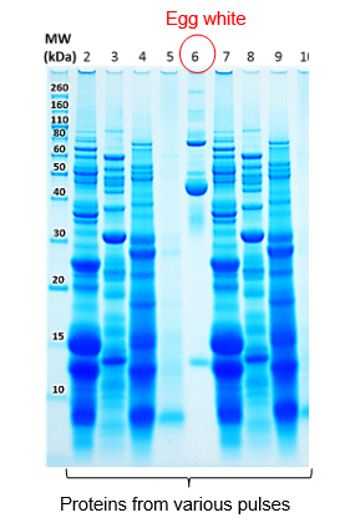

Figure 2 shows an SDS-PAGE gel of egg white and various pulses. SDS gel separates the proteins based on their molecular size. Smaller proteins are on the bottom of the gel and the larger ones on the top. It can be clearly seen that egg white has fewer and larger proteins than pulses (which have smaller proteins) and also fewer proteins of variable sizes. Research on plant proteins is complicated as they are almost always mixtures, meaning purification of these proteins to a single protein has been challenging.

Some of the most difficult challenges food manufacturers face when removing egg from cakes, sponges, custard-type fillings and desserts include the loss of structural properties. The structural integrity of a cake is largely created by the gelling function of the egg white proteins upon heating. Finding alternative ingredients which gel and set in the same way can be incredibly difficult whilst also needing to consider the ingredient’s solubility, stability, cold and hot swelling capability, and of course cost. Some ingredients that have been tried include modified starches, gums, pectins, and mucilage forming seeds such as chia and linseeds.

Egg white proteins (ovoglobulins) that aid with foaming are a challenge to replace. Aeration in batters is helped by the egg whites that stabilise air bubbles created during creaming or mixing. These bubbles are further expanded by the baking powders that release gases on heating. The main function of the ovalbumin is to convert the liquid foam created during the whipping process into a solid foam by thermally setting the protein structure during baking. Without this functionality, it is increasingly difficult to obtain the structure found in cakes that use eggs. These two functionalities are linked because, with egg in cakes, the stabilised foam is produced during mixing and the structure is set during baking.

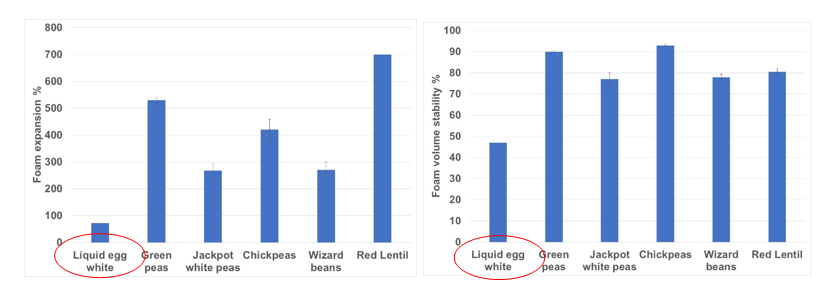

Trials have been performed that look at replicating the foaming capabilities of egg by using different pulse, legume and bean aquafabas, and these show some success. Plant protein fractions rich in albumins (e.g. pulses) have shown good foaming properties, similar to that with egg white (Figure 3).

Trials have been performed that look at replicating the foaming capabilities of egg by using different pulse, legume and bean aquafabas, and these show some success. Plant protein fractions rich in albumins (e.g. pulses) have shown good foaming properties, similar to that with egg white (Figure 3).

However, the heat stability of some of these foams, and their capability to coagulate, gel and provide structure on heating, has fallen short when added to cake recipes with flour, fats, sugar and other ingredients. Interactions with the alternate structure-forming and gelling ingredients such as starches, gums and seeds are complex. There is still a lot work that can be performed in this area.

Increased consumer demand for plant-based products has led to significant focus and developments in the field of novel sources of plant-based ingredients that are free of common allergens, are more cost-effective and have improved quality. These ingredients, individually or in combinations, could provide suitable replacements to animal-based ingredients in various food products, including bakery products. Alternatives which replace some or all of these functionalities could help companies develop products which are suitable for the growing band of consumers following vegan, plant-based or flexitarian diets.

Need help with reformulating your products?

Our experts have you covered. Whether you’re looking to replace egg and dairy ingredients with non-animal-origin alternatives or you’re seeking support with product innovation to meet nutrition and health targets, contact us to find out how we can help. Email support@campdenbri.co.uk or call our switchboard on +44(0)1386 842000 and they will be happy to direct your call to the relevant person.

This article was first published in European Baker & Biscuit.

Michael Adams

+44(0)1386 842284

michael.adams@campdenbri.co.uk

About Michael Adams

Mike has worked in the food and beverage industry since 2006. Before joining us at Campden BRI in 2016, Mike worked in technical, quality and R&D roles within Mission Foods, PepsiCo, and Holland & Barrett. Mike studied for a BSc (Hons) in Microbiology at the University of Manchester, graduating in 2005.

Mike’s team support various clients, providing innovation services, research and analysis across a wide range of products, using our state-of-the-art laboratories and pilot plant facilities.