Reducing food waste – what impact does ingredient age have on shelf-life?

15 January 2021 | Linda Everis, Section Lead - Microbiology Safety and Spoilage

The Food and Agriculture Organisation (FAO) of the United Nations estimates that if food waste was a country, it would be the third-highest emitter of greenhouse gases after the US and China. Alarmed? With tonnes of food wasted in the UK each year, you’re right to be.

Food manufacturers tolerate roughly 5% waste within their food processes under normal production, but often look for ways to reduce it. Making a product using ingredients that are a day or two old (instead of discarding them) is one way that manufacturers can attempt to reduce their overall food waste. This is common practice, assuming that the ingredients are used within their shelf-life and it is considered in the life of the product in which they’re incorporated.

Download the complete Maximising Shelf-life eBook, for free, to unlock the tools for measuring and maximising the shelf-life of your food and drink products whilst ensuring their safety and quality.

Being open to using older ingredients like this effectively extends their life, which provides greater flexibility and scope to make use of them before they’re discarded. On paper, this sounds like a win-win scenario: food waste is reduced while manufacturers have more time to use their ingredients before they’re deemed unacceptable. As food manufacturers consider incorporating one- or two-day-old ingredients into their products to reduce food waste, food safety must, of course, remain a priority.

This was recently highlighted by the Foods Standards Agency when, upon announcing its research priorities, it was made clear that reducing the impact of foodborne pathogens was one of its focuses. So, for a product made with several ingredients, what impact does the ingredient age have on the final product’s shelf-life? Our microbiologists at Campden BRI used coleslaw to find out.

Coleslaw: the model product

For products like coleslaw, it’s easy to think of them as their own entity, one that’s not dependent on the sum of its counterparts - but, of course, it is. A number of ingredients are brought together to create the final product, which then has a single shelf-life attributed to it.

Each of these ingredients may be at a different stage of its own life. You’d assume ingredients at the start of their life would create a final product with a longer shelf-life (due to a lower microbial loading than ingredients later in their life), but is this the case in practice?

We selected coleslaw because it contains three ingredients - raw onion, carrot and cabbage - with potentially high levels of microflora that could increase over time during storage.

Ingredient age and coleslaw shelf-life

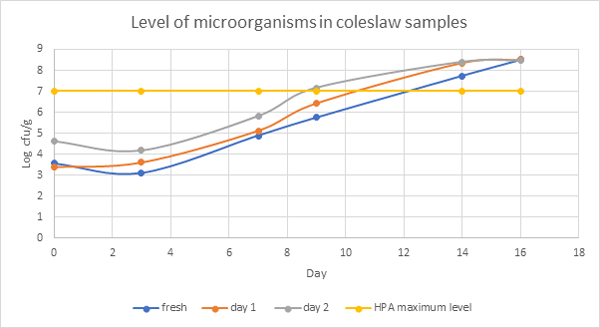

Three batches of coleslaw were made with ingredients of varying age (including fresh, one day old or two days old). They were then stored in a chilled environment and assessed over a 16-day period. These were sampled at specific intervals to determine whether the microbial count had exceeded an unacceptable amount. Guidance produced by the Health Protection Agency (HPA) - now part of Public Health England - stated that, for coleslaw, a total aerobic count and level of >107 cfu/g is unacceptable. In this context, ‘unacceptable’ means the product might appear spoiled, so it may not be suitable for consumption or sale. So, once exceeded, this was the level that would deem the end of the coleslaw’s shelf-life.

What did we find?

Our results show just how much the shelf-life of coleslaw will vary depending on the age of the ingredients used to prepare it; a difference of days. As you’ll see from the graph, coleslaw made with two-day-old ingredients reached an unacceptable level of microorganisms (and therefore the end of its shelf-life) in just nine days. The coleslaw made with one-day-old ingredients reached the same level after ten days, while the coleslaw containing fresh ingredients lasted an extra two days – its shelf-life ending after a total of 12 days.

Also worth noting was the initial microbial load of the two-day-old coleslaw at day zero: at least one log higher than the other two recipes. This will have influenced the shorter time to reach unacceptable microbial levels.

Fig 1: Graph shows the increase in microbial load of the three batches of coleslaw containing ingredients of varying ages, including the point that they breach the HPA maximum level of 107 cfu/g.

Although it cannot be confirmed without a study like this, similar results may arise in other products. In fact, the impact of using older ingredients could be even greater.

What does this mean for the industry?

Food manufacturers assign their final product’s shelf-life with the individual ingredients in mind, so the final product should never contain ingredients that spoil during that product’s life. Increasing the life of ingredients is one way in which food waste could be reduced – but it does have drawbacks, which need to be carefully considered. Trials would need to be carried out to show that a product remains acceptable with the same shelf-life, or indeed if the use of older ingredients would require a shorter shelf-life for a final product.

Overall, the results of this research have shown that ingredient age can have a significant effect on the achievable shelf-life of a final product and, therefore, should be considered in shelf-life trials. As this research has provided some light on just how quickly a product can reach an unacceptable level of microorganisms when made with ingredients of different age, we hope that this insight will provide scope for food manufacturers to further reduce food waste in the future.

Of course, each product behaves differently, so if you’re looking to test what your final product’s shelf-life would be when made with ingredients of varying ages, then this is something that our team at Campden BRI can help you with. Get in touch to find out more – we’d love to hear from you.

About Linda Everis

Linda has a wealth of knowledge, experience and expertise from her time in Microbiological Analytical Services and Microbiology Safety and Spoilage. She joined Campden BRI in 1995 as a Senior Technician in the Microbiological Analytical Services group having graduated from the University of Wales Aberystwyth with a BSc in Biology.

Alongside the expert support that Linda provides to our members and clients, Linda conducts project work and research, and has been author and co-author of articles and papers for a variety of microbiological publications and Campden BRI reports.

Linda also lectures on shelf-life, challenge testing and predictive microbiology for our many training courses and seminars.

Evaluation of microbiological shelf life of foods (Second edition) 2019

Our recently updated shelf-life determination guidance, that is backed by expert advice and practical shelf-life assessment, has been aligned with new EU regulation and recommendations for setting a shelf-life.

How can we help you?

If you’re looking to test what your final product’s shelf-life would be when made with ingredients of varying ages, contact us to find out how we can help.