From October 2018

From October 2018

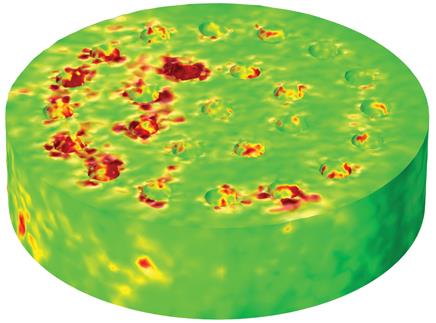

Modelling in the food industry

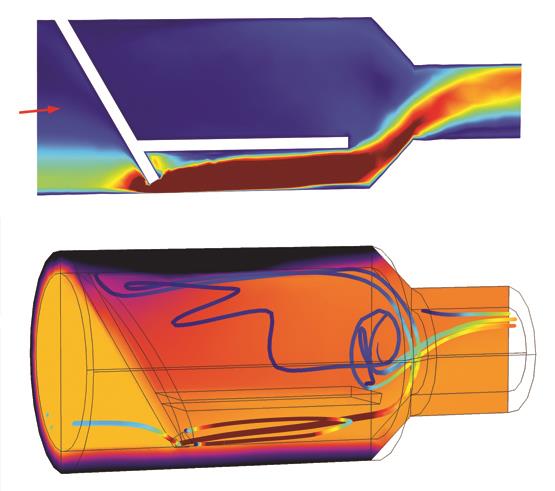

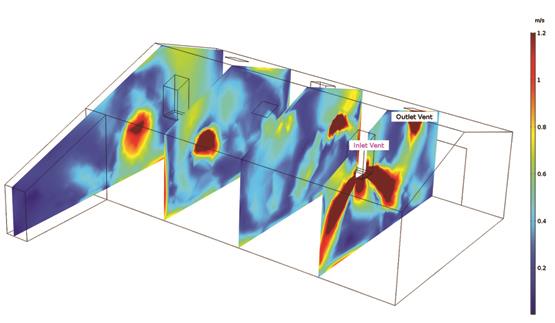

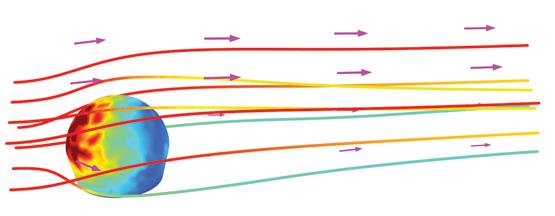

More companies in the food and drink industry are turning to mathematical modelling to develop and optimise their processes. We have, therefore, invested in a finite element modelling (FEM) tool capable of modelling the behaviour of food, drinks, packaging and factory environments in real life situations.

The technology allows multiple situations to be modelled quickly and cheaply to problem solve, optimise food and drink processes or to assess the effect of changes. The 3D physical modelling capability is very flexible and is suitable for a variety of situations such as gas/liquid flow, heat transfer, mass transfer and solid mechanics.

The modelling technology could be used to model:

- Food structure and complex microstructures

- Heat transfer of cooking products

- Fluid dynamics and diffusion

- Loading stress in packaging

- Flows through process equipment and factories to aid hygienic design

For example, we have modelled:

The software adds to existing technical and scientific expertise and equipment that make us a partner of choice for industry.

This modelling technology will also aid a member funded research project - design and modelling of the impact of food structure on food texture. The project aims to develop an improved capability to design products with the required texture by modelling the effects of differences in structure and understand how process conditions can be used to create the required structure for a range of product types. The project will demonstrate these capabilities through case studies, evaluate the effect of reformulation on texture and establish expertise.

Get in touch to find out more about modelling food and drinks.

Andrew Bosman

+44(0)1386 842471

andrew.bosman@campdenbri.co.uk