Blockchain and emerging approaches supporting food safety management systems

7 January 2020 | Richard Leathers, Global Quality Lead and Andrew Collins, Global Safety Lead

Blockchain

Introduction

The digitisation of food and drink supply chains is here to stay. If you work in manufacturing, technical, retail or logistics, we all want (and need) visibility of data for products and raw materials from the moment they are planted in the ground to the time they are consumed.

A blockchain, in simple terms, is a growing list of records (called blocks) that are linked using cryptography. Each block contains a cryptograph hash of the previous block, a timestamp, and transaction data. While these blocks are linear, Digital Ledgers are a progression from this in that they can allow many-to-many visible processes, with permissions.

Blockchain technology was first outlined in 1991 by Stuart Haber and W. Scott Stornetta, who wanted to implement a system where document timestamps could not be tampered with. It wasn’t until almost two decades later, with the launch of Bitcoin in 2009, that blockchain had its first real-world application. Bitcoin is a crypto-currency that is used to reduce the charges and time of cross-border transactions. The blockchain is a distributed ledger that enables peer-to-peer transaction in one of the safest environments. Transactions performed through Blockchain / Digital Ledgers are made public, therefore transparent.

However, the much-referenced supply chain collaboration between Walmart and IBM to trace a box of mangoes via blockchain technologies and digital ledgers must not simply be seen as being about a crate of fruit. To be meaningful, we need to look beyond the test itself, to what we want to achieve. Can we gain assurances on: authenticity and provenance; modern slavery; product yields and waste reduction; raw material and water usage efficiencies; as well as quickly giving us granularity and visibility of food safety and quality in complex supply chains?

Download our FREE Supply Chain Resilience eBook today! Thrive in a changing environment by being prepared, agile and resilient.

The harsh lessons learnt from the “Horse gate” issues of adulteration of beef with horse in 2013, showed the food industry that often we didn’t have sufficiently robust levels of traceability, particularly when the items were purchased via agents, traders and brokers. Since then, additional certification checks, and balances have gone some way to help to bridge this gap with traded goods. We must also ensure that reactions to any food safety, quality and authenticity issues and incidents are not short-term, sticking plaster fixes just to keep either the customer or auditor appeased.

From these adulteration incidents, many of the steps and systems developed and implemented at the time were reactionary. It is far better to use digitisation and technological advances to enable us to be proactive and to be able to make informed, science and knowledge-based decisions. This is not just limited to Vulnerability Assessments and adulteration, where informed and effective horizon scanning underpins our actions. We also need to utilise technology and emerging approaches in areas such as: allergen management (particularly noting the impact of “Natasha’s Law”); supplier approval and monitoring (which is frequently a non-conformance at certification audits); ethical, environmental and financial good practice; and food safety itself, also considering other emerging systems such as “Bowtie” and “Swiss Cheese”. There will be a further Campden BRI document covering these emerging systems and some of the future services offered in these areas.

The matter of trust must be addressed. Often, a supplier will have done a large amount of work to source ingredients and raw materials at the best price, for the best quality while assuring food safety. Often, this is commercially sensitive information that will give the supplier a significant advantage over its competitors. The supplier has the dilemma of maintaining business-critical confidentiality, while trying to embrace digital advances and an open and honest customer relationship.

Additionally, for some small suppliers, manufacturers, traders and growers, their understanding of IT systems may be limited. Therefore, any digital platform must be simple, reliable, easy to use and well supported. Proven technology in a rapidly advancing sector must be fit for purpose across the entire food chain, encompassing SME’s and agents up to multinational manufacturers.

The true use and purpose of digitisation is to efficiently and effectively provide assurance to the user and that the entire supply chain is appropriately controlled. It is not about gathering masses of data, ticking a box to say we have a system or performing a smoke and mirrors traceability exercise to keep someone in the chain happy. Digitisation can be the perfect vehicle for supply chain compliance, if it is designed correctly, robustly tested and is fit for purpose.

Advances and perceived benefits of Blockchain / Digital Ledgers

The consensus is that “blockchain” would be a perfect system or method for the food industry to adopt.1,2,3,4, 6,7,8

It is felt from many sources that it will improve the transparency and management of the food chain allowing all parties from within the supply chain to view real-time information throughout the process.1,2,3 This in turn provides a log of the products provenance which will also give consumers added confidence.2

The history of a product from origin to where it is in the present time can be traced through blockchain. Moreover, this type of accurate provenance tracking may be used to detect frauds in any part of the supply chain.12 The question posed, “Is the beef really Irish?” for example. This, however, is dependent on the information being inputted into the blockchain being accurate and honest.5,6,7

One of the key advances in food fraud management since “Horse gate” has been the creation and growth of FIIN (Food Industry Intelligence Network). FIIN was established by industry technical leaders to share intelligence on food authenticity and traceability.18

According to a survey of supply chain workers conducted by the American Productivity & Quality Center (APQC) and the Digital Supply Chain Institute (DSCI), more than one-third of people cited reduction of costs as the topmost benefit of application of blockchain in supply chain management.

When blockchain is applied to speed up administrative processes in supply chains, the extra costs occurring in the system are automatically reduced while still seeming to guarantee the security of transactions.12

In other interesting developments, Italian dairy company, Spinosa, have used blockchain technology to certify its PDO (Protected Designation of Origin) Mozzarella di Bufala Campana, complete with a blockchain label and QR smartcode. Manufacturing giants Barilla have been working with IBM Italia and inserted into blockchain based on IBM cloud infrastructure all the data related to cultivation, watering, and application of plant protection regarding plantations of basil, which will then become Barilla brand pesto sauce. They have reported that if the pilot is successful, the company will be ready to insert all of its products in the blockchain: from cereals to tomatoes and milk.

In retail, hypermarket Auchen Retail Italia, working with Big Group and the technology partner Te Food have been tracing the organic carrot supply chain. Tracking data comes using QR codes contained on product labeling. The firm’s aim is to ultimately trace 40 food products across 19 regions in the country and as many as 1,500 retail outlets. Similarly, at the Asset conference 2018 in Belfast, Professor Chris Elliot offered delegates the opportunity via QR codes to analyse “Downstream Hybrid” beer (pictured left), produced by Ireland Craft Beers.

These examples demonstrate the potential of a blockchain / digital ledger type system assisting in brand protection and organic, Identity Preserved and high provenance materials and products. Other pilot systems include: Moyee Coffee in Ireland; Alibaba’s “Food Trust Framework”; AB InBev’s cassava crop; Topco and seafood; Nestlewith several commodities; and Unilever/Sainsbury’s with tea from Malawi.

Further examples of the authenticity of organic items being targeted, was during Operation Opson VIII with the growing trend of products falsely claiming to be organic in order to be sold at higher prices. An action led by the EU Commission with the support of Europol was run across sixteen EU Member States to detect fraudulent practices pertaining to this field. More than 90,000 tonnes of suspicious organic products were checked, after which nine individuals were arrested. The illicit practices uncovered included the use of unauthorized substances, the diversion of conventionally produced food to the organic market and the use of falsified documents to blur the traceability of the products.17

Also, during Opson VIII, a targeted action was run across fourteen European countries in order to uncover possible fraudulent practices related to coffee labelled as 100% Arabica. With the support of Europol and the EU Commission, the action focused on the substitution of pure Arabica coffee (coffee variety of the highest quality) by cheaper lowland coffee (Robusta). In total, nearly 400 coffee samples were analysed as part of this action. For the first time in the history of Operation Opson, a laboratory cooperation was initiated and carried out within this investigation.

Potential limitations

However, there are potential obstacles to acknowledge. In many cases, supply chains are already moving billions of transactions and data, often in real-time. The systems are not perfect, and many supply chains have issues with data that is stored and disparately formatted, difficult to access, or hard to visualise or analyse in the context of Big Data. However, well-managed central databases with good data management, combined with supply-chain visualisation and analytical prowess, can already be achieved at scale today.

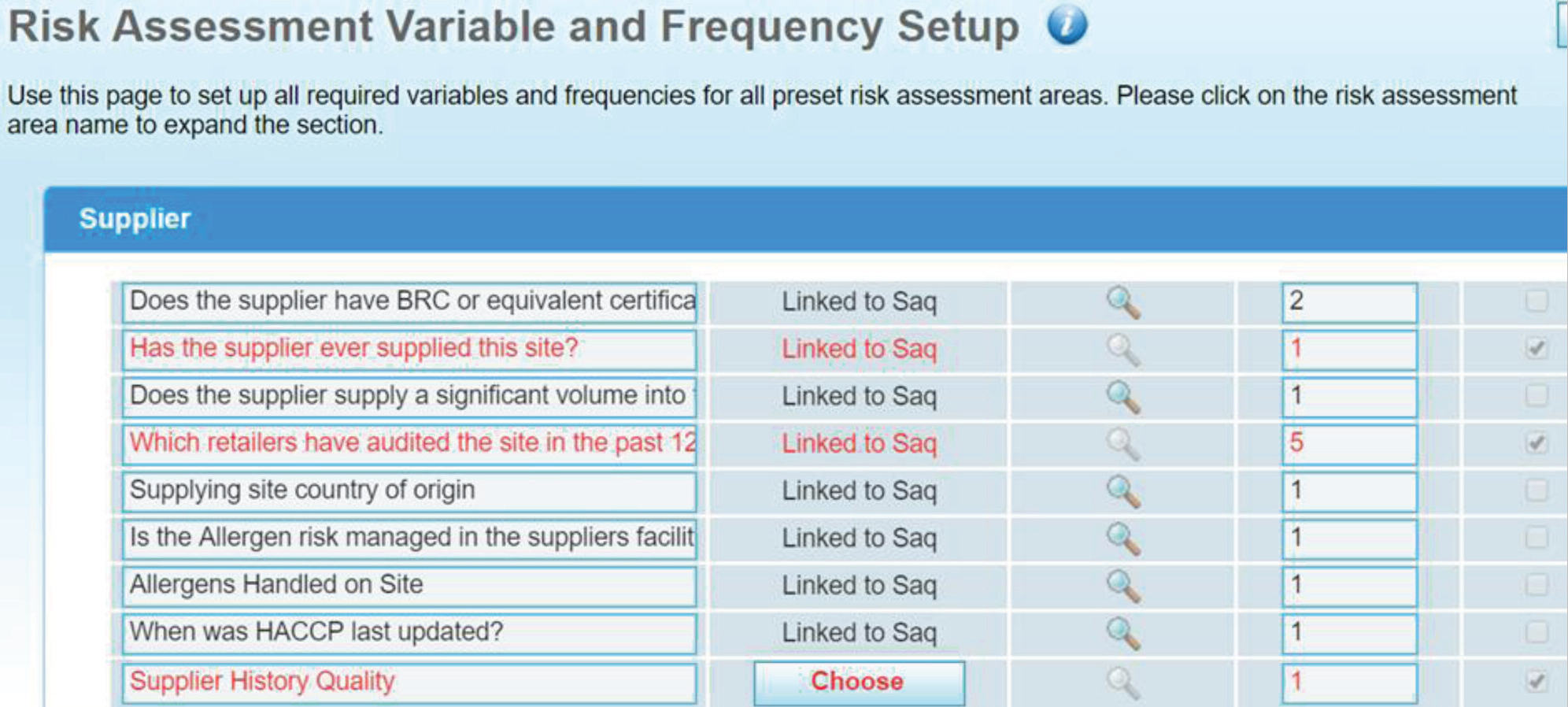

One organisation at the forefront of facilitating the integration of emerging technologies via digitisation and best practice is Qadex, who offer supply chain solutions for companies including Campden BRI members such as Birds Eye, Quorn, Aunt Bessie’s and Britvic.

Some of the Qadex mapping and risk evaluation tools (screenshot above) are now looking to incorporate updated elements of the recently reviewed Campden BRI Guidelines 65 (Risk evaluation and management of raw materials)and 72 (TACCP / VACCP). By doing this, we not only get the tracking and traceability that is required, but also see the big picture though effective use and analysis of this data.

Looking at existing methods of traceability and assurance, we should ask ourselves if they are truly deficient. With many current retail packs of fruit, vegetables, meat and other items, it is possible to print the name of the farmer or grower on the product, so how much more do we need?

Blockchains are either open or permissioned. Which means open access or restricted access and currently the supply-chain world may be unlikely to accept open access because its users don’t want to reveal proprietary details, such as demand, capacities, orders, prices, margins, at all points of the value chain to unknown participants. This means most supply-chain blockchains would need to be permissioned, with access governed centrally and restricted to known parties who may be limited to certain segments of data.

In theory, this allows public or private verification of each proposed block. However, it is unlikely that there will ever be public verification of proposed blocks in the supply-chain world when all the parties are known. When the number of trusted parties is small, the need to independently validate consensus protocols used in the public domain is limited.11 Once again, this is the block-to-block versus the many-to-many scenario.

Government departments (competent authority) and certification and auditing bodies (such as those working with BRCGS or FSSC) would still need to audit, among other certification requirements, the supply chain data to assure that data is correct and has not been tampered with and is correct to the product.13 There may also be audits by customers and / or retailers to satisfy commercial interests related to the SKU and their own specific codes of practice, therefore the audit burden (perceived as a problem to many manufacturers) may not be reduced.

Despite the identified potential benefits of blockchain in single ingredient products, such as fish14 or a mango, where the data of the product is simple and easily computable; more complex multiingredient products, such as a pizza or a ready meal, would take a larger amount of computing power, potentially reducing the speed and efficiency and relying on the quality of the data from the suppliers of these ingredients.15

Blockchain / Digital Ledger technologies summary

Blockchain technology has been proven to be effective, but could be limited in performance, scalability, and confidentiality.16 It could be the technological advancement we have been in search of that enables us to be proactive, preventing further incidents of adulteration, and provide the full traceability of products through the supply chain, that would benefit both buyers and suppliers of products.

Given the uncertainty in the food industry of the impact of the UK leaving the European Union, particularly in terms of border control documentation, it could be argued that if a fully integrated and mature blockchain / digital ledger type model had been in place, then assurances for food products cross-border would be more straightforward.

Maybe the beauty of blockchain and digital ledgers is not in the technology and traceability per se, but in the added value it can also bring via the tracking. Parameters such as temperature, ripening criteria, moisture levels, nitrogen controls and many other elements can be consequentially monitored throughout the product pathway and then interrogated and analysed accordingly.

Using algorithms and predictive modelling to analyse data has been around for some time in areas such as milk fat yield projections during dairy flush periods and for accurate estimations of usage and returns of lettuce, salad and other vegetable items at times of seasonal change. The further use of these tools can then give all parties visibility of real-time changes to risk profiles for food safety, quality and authenticity.

Perhaps the box of mangoes referenced above can then not only be traced upstream and downstream. It can also be guaranteed to arrive at the consumer as a safe, good quality product with perfect ripeness, provenance and identity preserved, with minimal or zero wastage, using a precise and controlled water consumption, optimal electricity and with associated ethical and environmental guarantees. This gives the grower, trader, packer, distributor, retailer and customer a fair price to ensure future commercial and economic viability.

Blockchain / Digital Ledger conclusion

It is important that food and drink supply chain providers are aware that the challenges with blockchain and digital ledger implementations will continue through their development, as they are still emerging and developing technologies. Evidence has shown that the single-to-single data links of a true blockchain may have limited benefits outside of grocery or commodity type materials in linear supply chains. Digital ledgers though, can offer many-to-many data links across complex products and supply chains that can be interrogated and analysed.

The true benefit then lies in the analysis and output of this information. This should not be just for traceability purposes, but lies in helping to assure food safety, quality, legislative and authenticity compliance. Artificial intelligence systems, algorithms around “Big Data” and predictive modelling will be further developed to support the raw data to assist in providing these assurances.

About Richard Leathers

Richard Leathers joined Campden BRI in September 2011, and has worked in the food industry for 4 decades.

Richard started working with Dairy Crest and subsequently worked for both Heinz, Unilever, Best Foods and Kanes Foods. Working in the areas of HACCP and Quality Management Systems, Richard also has experience within the fresh produce sector, as well as analysis systems in the milling / baking areas, and is a BRCGS qualified lead auditor.

Richard has contributed to several publications and guidelines, including those for TACCP, VACCP and HACCP / Risk Evaluation and is also trained at advanced level by EHEDG (European Hygienic Engineering Design Group).

About Andrew Collins

Andrew joined Campden BRI at the beginning of 2009. With over 30-years’ experience in a wide range of food businesses (including catering), his current role focuses on consultancy work with the holistic and practical application of food safety management including the role of HACCP and good hygiene practices.

He is a certified BowTie practitioner, and is one of the few food safety experts globally using BowTie methodology – a barrier, risk-based thinking approach to risk management in the food businesses. This approach enables businesses to build holistic, resilient and adaptive systems in a rapidly changing environment.

Andrew also works on supply chain management, agriculture and water use, animal feed and traceability. Plus, he’s part of the team that manages hygiene and allergen management.

White paper download

Click below to download a copy of the white paper in PDF format

How can we help you?

If you’d like to find out more about food safety management systems, contact our support team to find out how we can help.

References

- 1 Megan Ray Nichols https://foodsafetytech.com/column/blockchain-improves-visibility-foodsupply-chain/

- 2 Saif Rivers https://www.ibm.com/blogs/blockchain/category/blockchain-in-food-safety/

- 3 Tim Levant Yurdum https://www.ibm.com/blogs/blockchain/category/blockchain-in-food-safety/

- 4 Steven Burton https://foodsafetytech.com/column/blockchain-technology-drive-fsvp-compliance/

- 5 Radoslav Dragov https://foodsafetytech.com/column/blockchain-technology-drive-fsvpcompliance/

- 6 Dr Ron Wacker https://www.tuv-sud.com/home-com/resource-centre/stories/food-blockchain

- 7 Sylvain Charlebois http://theconversation.com/how-blockchain-technology-could-transform-thefood-industry-89348

- 8 Sean Crossey https://www.newfoodmagazine.com/article/36978/blockchain-food/

- 9 Jenney Splitter https://www.forbes.com/sites/jennysplitter/2018/09/30/what-can-blockchain-reallydo-for-the-food-industry/#1c61e1d3488e

- 10 https://www.quora.com/How-can-blockchain-improve-supply-chains

- 11 https://www.mckinsey.com/business-functions/operations/our-insights/blockchain-technology-forsupply-chainsa-must-or-a-maybe

- 12 https://hackernoon.com/how-is-blockchain-disrupting-the-supply-chain-industry-f3a1c599daef

- 13 http://iranarze.ir/wp-content/uploads/2018/11/E10145-IranArze.pdf

- 14 https://papers.ssrn.com/sol3/papers.cfm?abstract_id=3319440

- 15 file:///C:/Users/jamesc/Downloads/Rapport%2004-2019.pdf

- 16 https://www2.deloitte.com/content/dam/Deloitte/lu/Documents/technology/lu-blockchain-internetthings-supply-chain-traceability.pdf

- 17 https://ec.europa.eu/food/sites/food/files/safety/docs/food-fraud_succ-coop_2019_orgprods_qandas.pdf

- 18 https://www.campdenbri.co.uk/news/fiin.php