Are your cooking instructions correct?

12 August 2019 | Greg Hooper, Microwave and Thermal Process Specialist

BRCGS Global Standard Food Safety Issue 9 – Clause 5.2.4: Cooking (heating) instruction validation

BRC Global Standard Issue 8 for Food Safety was released in 2018 and the first audits began earlier this year. BRC is the world’s most widely-applied food safety standard. One significant change in Issue 8 is the inclusion of on-pack instruction validation, known as Clause 5.2.5: Cooking (heating) instruction validation, for the first time.

What is instruction validation and why is it so important?

Instruction validation relates to the need to ensure that cooking and heating instructions for consumers are tested rigorously, to ensure that food is safe to eat and of acceptable quality. From a commercial perspective it’s worth remembering that understanding and incorporating scientific instruction validation principles at the start of any NPD, product changes or even validating existing instructions, will allow you to achieve both of these aims. For consumers to have confidence in heating instructions they need to be meticulously validated. For food safety it’s important to work to worst-case scenarios rather than averages – essential when you consider the need to eliminate the risk from Listeria monocyctogenes, E.coli and Salmonella spp.

The thermal process and its equivalent

The target combination of minimum temperature and cooking time is known as the thermal process. It is vital that this is measured in the slowest heating location (cold spot) of worst-case product samples - although this cold spot can be notoriously difficult to locate. For most chilled and frozen products which are not considered ‘ready to eat’ the thermal process required is 70°C for two minutes, or an equivalent, i.e. a higher temperature for a shorter time or vice-versa.

The table below shows equivalent process times at temperatures above and below the 70 degree - two-minute target.

| Temperature at the slowest heating point (°C) | Time required at the reference temperature to achieve an equivalent process (minutes) |

|---|---|

| 60 | 43.48 |

| 65 | 9.30 |

| 70 | 2.00 |

| 74 | 0.43 (26 seconds) |

| 80 | 0.09 (5 seconds) |

Equivalent processes to achieve 70°C for 2 minutes

You’ll probably be quite surprised at how much longer it takes to reach the equivalent thermal process at 60°C and how it is only a few seconds at 80°C.

Finding the cold spot

It is imperative that the cold spot is identified and the temperature at this location is monitored using a probe. You can probably guess that it is likely to be at the most dense or thickest part of a product, but it isn’t always that simple. It may not be where you’d expect, for instance during microwave heating it is possible that the cold spot may be near the product surface (depending on the microwave field patterns).

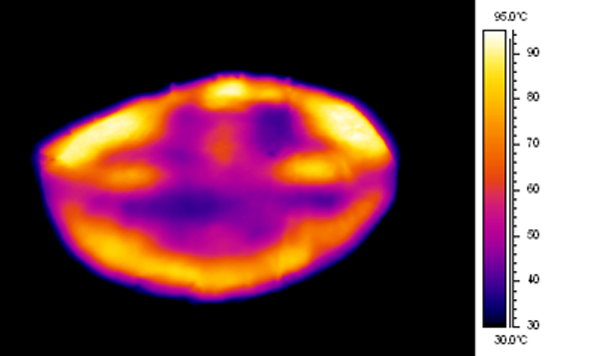

The thermal image below shows the complex heating pattern of a microwave heated product, with cold spots at the surface not in centre as may be expected (white shows temperatures of above 90°C and black/blue as much colder, below 40°C:

If the cold spot is missed and this slowest heating location does not receive the required minimum thermal process, then there is a possibility that any food poisoning bacteria present will not be sufficiently killed and consequently pose a risk to consumers. Using a ‘hedgehog’ device (multiple probes set into a grid array to measure several product location temperatures at the same time) or a given number of temperature measurements may not locate the cold spot, as it may well lie between the probes. Careful and thorough probing of the sample is necessary.

Post heating stand times must also be considered when perfecting heating instructions – as cold spot temperatures can continue to increase due to conduction from hotter product areas.

Equipment – testing, calibration and selection

Accurate measurement of the thermal process at the slowest heating point (temperature and time) is, of course, essential when determining cooking instructions. This relates to temperature measuring devices, such as probes, as well as the appliances used to heat or cook food. When it comes to appliances, we need to consider how the different types behave. Gas, electric and fan oven variants all behave and heat products differently. Air flow rates, temperatures throughout the cavity, and peak and trough temperatures as thermostats cut in and out – all of these can vary.

With this in mind, it is not acceptable to use a single oven type e.g. non-fan-assisted electric oven and then assume a product will heat in a similar time in a gas oven at the same temperature setting or a fan-assisted oven operating at 20°C less. Further, correct instruction validation not only requires products to be tested on all three types of oven, but also that trials are replicated. At Campden BRI we suggest testing the same product five times in each appliance and the samples tested need to be worst case (e.g. thickest, heaviest, slowest heating).

Similarly, microwave ovens will vary, so care needs to be taken when picking the right ones for your validation testing (several ovens are needed with a range of different features and different heating patterns). Otherwise it is possible to develop instructions that will only work in the particular ovens used for the testing, and not in the majority of consumers' ovens! Microwaves with the same power rating can heat products differently. Factors which affect the way they cook include:

- the size of the cavity

- whether or not it has a turntable

- the internal finish – paint or stainless steel

- if it is a combination microwave – i.e. one which also has grill or hot oven

- where the microwave energy enters the oven cavity (e.g. top or side)

What will BRC 8 mean?

There are more issues to consider but hopefully this article has shone a light on some of the key areas on effective instruction validation required by BRC Issue 8. Fundamentally it underlines the importance of recognising that products and equipment are not homogenous - product thickness varies, different oven types behave differently, as do hobs, grills and microwaves (even those of the same wattage). By identifying the many areas where variations exist, the new standard highlights best practice and how to build greater confidence in on-pack instructions. Ultimately, it will help ensure that food safety and product quality standards are maintained and improved, which is great for both the consumer and the industry.

About Greg Hooper

Greg has worked here at Campden BRI since 1990, after studying Applied Science (Physics and Chemistry). As part of his extensive knowledge and experience in thermal processing and microwave cooking, he was instrumental in setting up the microwave heating category rating system used in the UK, and has travelled internationally assisting and advising on the safe development of microwave products and rating systems.

Cooking (heating) instruction validation white paper

Read our white paper on BRCGS Global Standard Food Safety Issue 9 – Clause 5.2.4: Cooking (heating) instruction validation.

How can we help you?

Do you have any questions or would you like to discuss your requirements? Contact our Support Team.

This article first appeared in International Food and Meat Topics