From August 2013 newsletter

From August 2013 newsletter

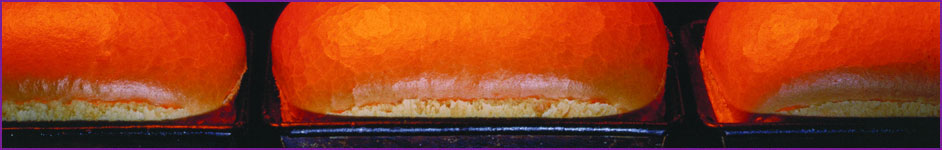

Energy reduction in baking

Energy demands in the bread making process are dominated by the oven step, and so there are financial and environmental benefits to reducing the baking time. Recent member subscription-funded research has shown how this can be achieved. Baking of bread traditionally targets a core temperature of 94-96°C, based on microbiological, enzymic and structural criteria. Anecdotal evidence suggests that this may be higher than necessary for some breads. Using white pan bread, this work investigated the impact of reducing bake time on bread quality, specifically loaf volume, texture, extent of starch gelatinisation and bread structure. For the target bread to contain similar moisture levels to existing bread, and with less water evaporated by the oven, water levels needed to be reduced in the recipe. This was achieved by using higher dough temperatures during mixing so the dough was softer for equivalent water.

20% reduction in bake time

A 6 minute reduction in bake time (equivalent to 20%) resulted in bread in which the starch was gelatinised and all other textural and structural parameters were similar to those for the full bake time, although an increase in oven temperature from 240 to 250°C was required to achieve the crust colour and strength. Operating to a lower core temperature will lead to energy reductions during the baking process. Further energy reductions can be achieved in mixing and proofing if lower water content but warmer dough is used.

Contact: Support Team

+44(0)1386 842291

support@campdenbri.co.uk