Bubbles in bread and aerated chocolate – it’s just air but it matters

7 April 2022 | Martin Whitworth, Principal Scientist

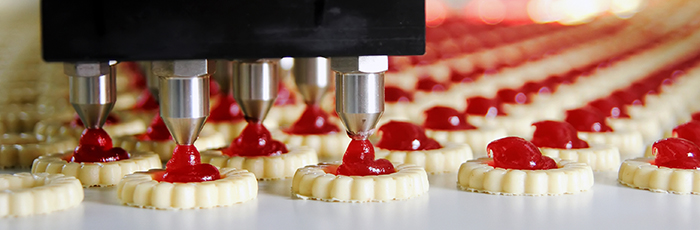

It might not cross your mind to add bubbles to your shopping list but they are an integral part of myriad aerated foods, including breads, cakes, ice creams, cereals, whipped cream, waffles or chocolate. These can be aerated intentionally, or not. Bubbles are incorporated into the food using various techniques and lend a distinctive quality of texture depending on gas content and bubble distribution.

Texture is one of the key elements to the commercial success of food. Developing or reformulating products typically requires the production and evaluation of many processes and recipe variations to identify those that give the required structure and texture. This can be time-consuming, involving the use of costly pilot production facilities and sensory panels. A Campden BRI member-funded research project studied the relationship between food structure and food texture in bread and aerated chocolate, thereby aiding product development.

So what was found?

For bread, several process variations were studied using sensory napping, Rapid Attribute Profiling (RAP) and instrumental texture analysis. Martin Whitworth from Campden BRI led the research and explained:

The main effect on texture was the moulding of the dough, which has the effect of changing the shape and orientation of bubbles. Four-piece moulding resulted in softer instrumental firmness and greater springiness”

This was described by sensory panellists as “moist” and “springy” as opposed to “rough” and “firm”. Martin added: “The higher bread porosity also resulted in softer texture, but this was not directly associated with any specific process variation. So, although changes in mixer pressure can be used to control the fineness of bread crumbs, it seems to be the moulding process, which controls the shape and orientation of bubbles, and the total porosity that are more important for texture”.

For chocolate, the project team established a small-scale facility, using the vacuum method to aerate it. Varying the type of dissolved gas and the vacuum pressure, the main effect was on the porosity, which was strongly correlated with many of the instrumental and sensory texture parameters. When a more soluble gas (carbon dioxide) and lower pressures were used, the chocolate had a greater porosity than when using air or nitrogen and a lower density. The sensory panellists described it as crumbly, with low firmness to bite, and having a high rate of melting.

And the rate of melting is a property that goes beyond the initial texture when first biting chocolate. Although not directly within the scope of the proposed approach to model the structure of foods at or before consumption, it was recognised that chocolate also undergoes transformations in the mouth. This project gave Campden BRI a first brief foray into the use of a method called Temporal Check-All-That-Apply (TCATA). Measuring change in sensory properties over time in the mouth, it provides additional discrimination of sample differences not identified on shorter-term assessment.

Ideas for tomorrow

This project allows us to increase our experience and expertise to tackle texture issues in many food and drink products, placing us at the forefront of global scientific innovation in this sector.

You might be looking to reduce cost by finding cheaper ingredients, improve or characterise quality, evaluate a product over shelf-life, reformulate for nutritional or labelling concerns or simply to compare your products against competitors. It is important to have the knowledge and skills to analyse, identify and objectively measure the impact of these changes on the final product.

No matter what your challenge may be, we consistently deliver innovative solutions, helping you optimise your product to put you in a much better position to conquer your market.

The Structure and texture of bread and aerated chocolate report is available to Campden BRI members .

Contact us today and speak with one of our experts who will help.

About Martin Whitworth

Martin has worked at Campden BRI and its predecessors since 1992. He has an MA and PhD in physics from Cambridge University, and an impressive number of food research publications from his time with us. He currently provides support and peer review for our research programme.

Martin specialises in physical characterisation of food products and ingredients including colour, structure and texture, with particular expertise in the application of imaging techniques and digital image analysis.

Martin has experience in cereal science and technology. He is a leading expert on bubble structure of doughs and baked products. He established our imaging laboratory, now part of our Food and Drink Microstructure team, which includes DigiEye colour imaging, hyperspectral NIR imaging and X-ray micro CT. He was the inventor of the C-Cell instrument for measurement of bread quality, and pioneered the use of X-ray tomography to study bread and cake structure during baking. He also carried out the initial research that led to the Branscan and Fluoroscan instruments for flour quality analysis.

How can we help you?

If you’d like to find out more about food texture, contact our support team to find out how we can help.

Are you a Campden BRI member who attends the MIG meetings?

- If not, you’re missing out on a whole host of exclusive benefits such as learning from industry-leading experts and networking with peers to overcome your challenges.