Solve your food product problems

28 June 2018 | Sarab Sahi, Rheology and Texture Section Manager

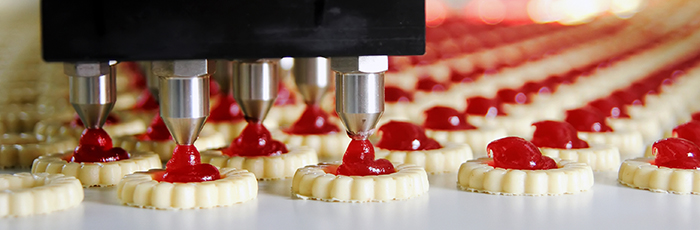

Food is becoming more complex with a growing number of innovative ingredients and processes used to make products tastier, healthier and cheaper. But complexity can increase the risk that things can go wrong with a product.

We are often approached by clients with questions related to the appearance, texture and rheology of their products, such as "Why is my product going soggy?" "Why are my biscuits cracking?" "Why is my mayonnaise thinning?" or "Why is my mousse sinking?" All these questions can be traced to problems with the physical properties of food.

The behaviour of food - from ingredients through to the finished product – often depends on the physical properties of the ingredients. Understanding the physical properties involved is key to investigating and solving technical problems that can arise.

Pinpointing the root cause of problems

Problems can arise during manufacturing, distribution or storage, so pinpointing the root cause of a problem can be tricky. It requires cutting-edge equipment to investigate and objectively measure things such as rheology, particle size, thermal properties, and product structure. And it needs someone who can understand and interpret the large amounts of data produced by these investigations.

For example, a client approached us to help them as large holes were appearing in their cake crumb. Once we had ruled out processing factors, we examined the whipping performance of the egg. Our measurements of foaming capacity and foam stability identified that the egg was inadequate so it was not possible to beat sufficient air into the batter and to stabilise the dispersed air bubbles. As a result, the air bubbles coalesced and caused holes to appear in the cake.

In another example we identified that a client’s cakes were collapsing due to high levels of sugar in the recipe. Sugar plays a key role in controlling the setting and stabilising the structure of products such as cake. Excessive sugar levels in a recipe can raise the setting temperature so that the structure may not fully set and collapse after baking. We tracked the problem to the effect of sugar on protein gelation and starch gelatinisation using thermal analysis (DSC).

Prevent manufacturing problems

But it’s not just about troubleshooting when things go wrong. You can prevent manufacturing problems and quality issues arising if you understand the physical properties of your ingredients and how they will behave during processing and the product’s shelf life. Prevention is always better than cure. Since processing problems can lead to production downtime and drive up ingredient and product waste, preventing problems arising in the first place can save you valuable time and money.

Our multidisciplinary experienced team can investigate and solve your issues so you can produce more consistent products and be assured that your product will remain in top condition throughout its shelf life.

How can we help you?

If you’d like to find out more about product problems, contact our support team to find out how we can help.

Are you a Campden BRI member who attends the MIG meetings?

- If not, you’re missing out on a whole host of exclusive benefits such as learning from industry-leading experts and networking with peers to overcome your challenges.