Metal can double seam assessment and troubleshooting

To discuss your needs

The integrity of double seam is crucially important to the entire production process of metal cans. Any double seam defects can adversely affect the quality and safety of food and drink products.

At Campden BRI, we provide complete double seam assessment and evaluation solutions for food and drink cans. Our experienced packaging team not only determine double seam defects but can also assist in identifying and understanding their root causes, giving you confidence that your consumers will receive a safe product.

We can assess internal and external dimensions for any defects and breaching of critical seam parameters using two methods:

- Manual seam teardown

- Sectioning with the use of a CMC Kuhnke seam imager

CMC Kuhnke seam imaging

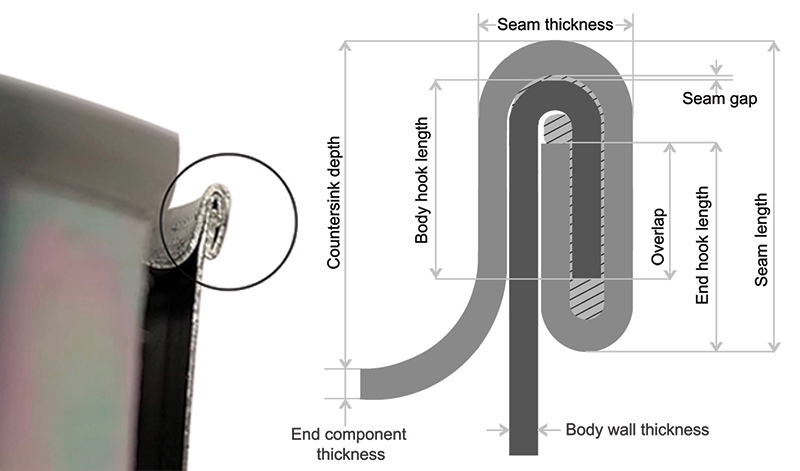

Double seam dimensional terminology

With a unique range of disciplines under one roof, we apply a bespoke and multidisciplinary approach to double seam assessment. This includes but is not limited to:

- Air pressure testing - to detect leaks from the double seam and the can’s body

- Internal vacuum pressure measurement - to test can integrity

- Compound weight and distribution

- Sterility testing - to detect any microbiological activity

- Small scale production trials including recipe preparation, carbonation, liquid nitrogen dosage, can seaming, processing and storage under various conditions. All can be supported with sensory assessment, elemental analysis and shelf-life determination.

Contact us and speak to our seam experts today. Our team will quickly assess and investigate your double seam challenges and support you with your unique needs.

You can rely on Campden BRI to protect your business. Partnering with us means being supported by a dedicated team with an unrivaled depth of knowledge and breadth of experience. For us, it is about more than just providing analysis and testing, it is about being there for you as a full-solutions partner. Whatever your needs are, we will work with you to find the right solution for your business.

Packaging training courses

Explore our packaging related courses including; Packaging technology for non-packaging technologists and MAP (modified atmosphere packaging) – an introduction

Are you getting the most from your Membership?

Watch our membership FAQ videos and find out more about Member Service Account spending, Member Interest Groups, help and advice

Key services

Package strength and integrity

Packaging must be able to withstand the rigours of distribution and storage.

Metal

Testing of canned products within metal packaging may be required for various reasons including product/pack compatibility.

Modified atmosphere packaging

Ensuring the correct gas composition and gas:product volume ratio is critical.

Packaging down the microscope

Microscopy can use a range of techniques to examine packaging materials including plastic and metal.

Packaging migration and taint analysis

Packaging must not transfer its constituents into food to the detriment of the food's quality.

Metal can double seam assessment and troubleshooting

We can assess internal and external dimensions for any defects and breaching of critical seam parameters

Where we refer to UKAS Accreditation

The Campden BRI group companies listed below are accredited in accordance with the recognised International Standard ISO/IEC 17025:2017 by the United Kingdom Accreditation Service (UKAS). The accreditation demonstrates technical competence for a defined scope of methods, specific to each site, as detailed in the schedules of accreditation bearing the testing laboratory number. The schedules may be revised from time to time and reissued by UKAS. The most recent issue of the schedules are available from the UKAS website www.ukas.com. Campden BRI (Chipping Campden) Limited is a UKAS accredited testing laboratory No. 1079