Blogs

Providing insight into the science and technology underpinning food and drink production. Contact us if you would like further information on any of the topics covered.

Top BRGCS and FSSC non-conformances – what we can learn?

Here we cover the key themes and focus areas that may be drawn from recent global non-conformance data of FSSC 22000 and BRCGS audits.

Canada’s front-of-pack nutrition labelling: Preparing for 2026

A crucial detail for businesses to understand is which foods will require the front-of-pack nutrition symbol, and which will be exempt.

Why accurate meat content analysis matters – and how the right lab can help

Measuring meat content might sound straightforward, but there are hidden complexities. Even small differences can lead to significant discrepancies between e...

PFAS in wine: What’s in your glass and how winemakers can stay ahead

With tightening global regulations and growing consumer scrutiny, the wine sector must be proactive in understanding potential risks.

Promotional restrictions in the UK for products that are high in fat, sugar and salt (HFSS)

Update: New HFSS regulations in England ban multibuy promotions on foods high in fat, sugar, or salt (HFSS). Retailers must now comply with stricter rules on...

Nitrites and nitrates – reduction in the levels that can be used in various food commodities in the EU

Here we cover more on this legislation, how this relates to the function of nitrites/nitrates within products such as cured meats, and what support we can of...

Bud fertility assessments – for yield forecasting and improved vineyard decision-making

Using dormant-season bud dissections as a tool for predicting vineyard yield; a look at the method and benefits of bud fertility assessments, and why we are ...

Bread and flour regulations amended to help protect health of babies in England

Get the latest information on new amendments to the 1998 Bread and Flour Regulations, which will help better protect the health of babies in England, Scotlan...

Benefit from our latest research

We invest in research to support our members and clients, develop our capabilities and services, and remain competitive. Here we cover some of the latest res...

Accelerated shelf-life testing for alcoholic beverages

How accelerated shelf-life testing is done for alcoholic beverages, why it matters, the pain points it addresses, when to use ASLT, and what our testing proc...

Multi-market food product labels – one size DOES NOT fit all

Using a single label across multiple markets can help to manage minimum order quantities and simplify the supply chain. However, individual approaches to mul...

The importance of allergen training in food and drink manufacture

Here we focus on key areas of allergen training – food allergen control, food allergen cleaning validation, and food allergen communication and labelling.

HFSS placement legislation: Assessing the impact and what comes next for the food industry

Results and recommendations from the University of Leeds’ studies on HFSS legislation impacts, associated recommendations for the food industry and how we ca...

Exploring the complexities of mycotoxins in food

Discover more about mycotoxins in food, the issues they can cause and what can be done to help mitigate their presence in our food.

What is allergen management and why is it business critical?

Find out why food allergen management is so crucial, the best way to manage food allergens and how we can support you with this.

GRAS reform on the horizon: Questions every food business should be asking

Discover more about the proposed shift in the United States FDA oversight of the GRAS pathway mechanism - this historically allowed food manufacturers to sel...

Working to decipher toxigenic profiles in foodborne bacterial pathogens

See what we have been doing to enhance our understanding and detection of foodborne toxins.

When a tiny change topples food quality: Lessons from the lab and factory floor

Explore how we support clients with investigating food product quality issues and provide the expertise they need to get back on track.

Showcasing the benefits of induction heating

Discover how induction heating works, its applications and benefits, and experience it for yourself with our production trials.

Investigating the efficacy of plant protein functionality as a replacement for egg

We have been evaluating the effectiveness of plant-based ingredients as egg replacers, focussing specifically on cake baking. See how our ongoing trials are ...

Most discussed hot topics resulting from our Spring on-site MIG meetings

Discover what issues matter most to our members and what we at Campden BRI are doing to support them.

Exploring the effectiveness of natural antimicrobials as an alternative to synthetic preservatives

Discover what we have been doing in the area of natural antimicrobial testing, to help support those thinking about adding natural antimicrobials into their ...

Why sensory acuity screening matters in food and beverage manufacturing

See how sensory acuity screening can help maintain the sensory quality and success of your products, and how we can support you through our sensory screening...

Nutrition policy developments: An update on the United States

From dietary guidelines for Americans to the latest on Front-of-Package nutrition labelling and more. We provide the latest on US Nutrition Policy Developments.

What is STEC and why is it a risk in sprouted seeds?

Having been accredited with an extension to scope for STEC detection in sprouted seeds (TES-MB-225), we explore why STEC is a risk in sprouted seeds and how ...

Nutri-Score vs Nutri-Mark? What are the differences in nutrition labelling schemes between the UK, EU and GCC?

Discover more about Front-of-Pack Nutrition Labelling (FoPNL) schemes and the differences between different regions.

Cooking instruction services: Why you should examine the scientific rigour offered by your service provider

We outline some key considerations to help you examine if your existing partner is delivering what you need.

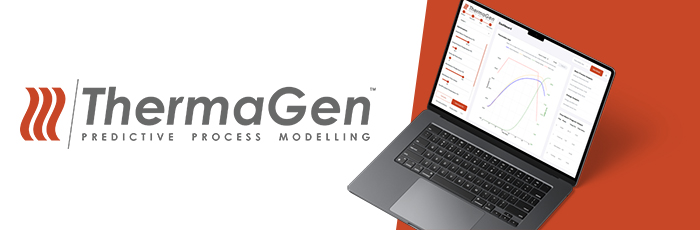

Save time, money and transform your thermal processing with ThermaGen

Campden BRI are excited to announce the launch of ThermaGen, an online application offering predictive calculation capability for those working in thermal pr...

Better understand your position in the marketplace with rapid sensory product benchmarking (UKAS Accredited)

Rapid sensory product benchmarking is a great, cost-effective way to get an ‘informed consumer’ perspective on your products.

Why partner with Campden BRI for your allergen testing?

With cross contamination from allergens in the food supply chain increasing, getting an accredited, knowledgeable and experienced food allergen testing partn...

Accelerated shelf-life testing of food and beverage products

Here we outline the services we offer in this area, signpost other useful tools, and unpack some of the key considerations and limitations for conducting acc...

Stay ahead of regulatory developments with horizon scanning

Find out how our horizon scanning solution can help you to respond more proactively to evolving regulatory environments.

Using sensory evaluation and quality planning for product quality management

Discover how sensory science and quality planning can improve product quality, supported by our consultancy, guidance, and training.

The value of bundling your challenge testing, shelf life, sensory analysis and consultancy through a single partner

Discover how besides food safety, food producers can save time and money when they bundle all their services with a single expert partner like us.

Helping food manufacturers manage the microbiological risk in low and intermediate moisture foods

Explore how we support food manufacturers in enhancing the management of microbiological risks in low and intermediate moisture foods.

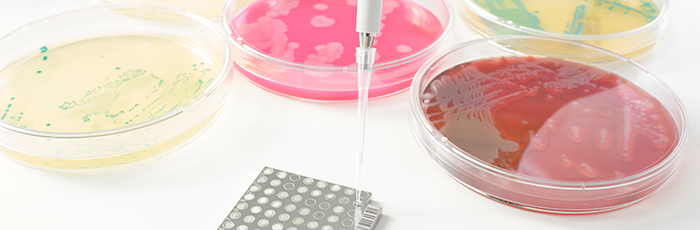

How proficient is your microbiology laboratory?

If you are concerned about your laboratory team’s performance, participating in a proficiency scheme can help.

Further strengthening our thermal processing service offerings

See how we have strengthened our thermal processing service with a wide range of support available around process optimisation and cycle development.

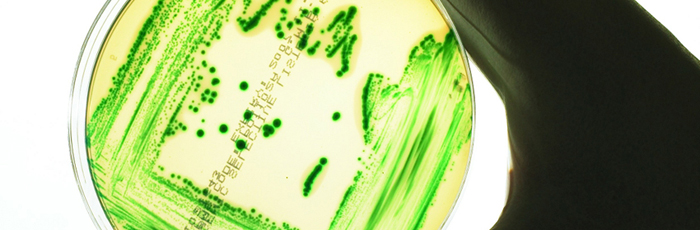

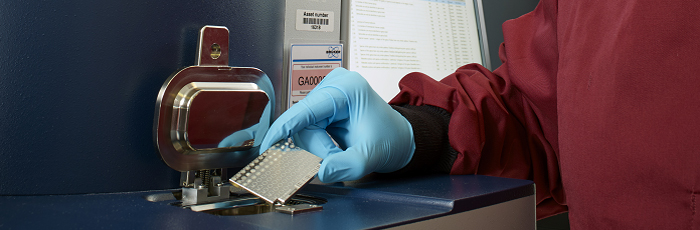

Fast, accurate microbial identification – why it’s important and how to get it

Identifying the microorganism present in a sample can help to understand the source and cause of the contamination. All so you can address the issue and prev...

Why carry out microbiological testing on food and drink products?

Microbiological testing serves various purposes, including meeting customer requirements, ensuring compliance, performing due diligence, release testing, and...

Insights from our Brewers’ Day event

Discover what we do to support our members in the brewing industry with a look at the highlights review piece from our recent Brewers’ Day event.

Supporting IFTSA competition winners with a UK tour and visit to Campden BRI

See what we do to support and nurture young talent on their career journey, through our many initiatives and partnerships.

Exploring the pathogenic challenges and uncertainties with low/no alcohol beer

Find out about the latest issues and research we’ve been exploring in brewing microbiology, which we will also discuss in more detail at our Brewers’ Day event.

Culture Excellence seminar 2024

See what we do to promote and support a strong, positive culture of food safety and quality at our ‘Culture Excellence’ seminar.

Insights from our Food Safety Risk Management seminar

See how we can support those with greatest responsibility for managing food safety risks, through topical updates from industry experts and networking opport...

Highlights from our ‘Hot topics in food microbiology’ event

See how we support the food microbiology sector, offer topical updates from industry experts and provide networking opportunities at our ‘food microbiology’ ...

Key insights from our SafePlate 2024 event

Read how we support the thermal processing industry, offer guidance with topical presentations from experts and networking opportunities at our SafePlate event

Our research journey to date – supporting the food and drink industry for more than 100 years

Research activities of the ‘Campden Experimental Factory’ and its subsequent iterations, what we do for the food and drink industry now, and how our latest r...

Our new pasteurisation optimisation research

To demonstrate that yeast ascospores can be used as a pasteurisation bioindicator for the validation of flash pasteurisation for various alcoholic and alcoho...

What you need to know about kiwifruit and other emerging elicitors of food allergy

Like for many crops, the use of kiwifruit is growing and changing across a range of food streams. This research shines a light on what food business operator...

Evaluating the food information, labelling and unintended food allergen presence of imported prepacked foods and drinks purchased online

Frequent food and drink product recalls occur globally due to incorrect labelling of food allergens.

The allergenicity of edible algae – implications for food business operators

Food business operators need to be aware of seaweed and algal derived products as potential sources of food allergens in their food chains, and what to do to...

Harness the power of sensory insights

The benefits and applications of sensory insights in helping clients make more informed and meaningful commercial decisions – for successful product developm...

The ultra-processed food challenge

UPF often describes the ingredients within a food or drink, not the necessarily the product itself. Nutritional research on UPFs has demonstrated some intere...

Key considerations for safe and successful reformulation

There are lots of reasons to replace ingredients and reformulate – but how do you do it safely? Here we explore some key considerations for the safe replacem...

Microbiological safety of plant-based meat alternatives

Plant-based food production often involves ingredients and processes that wouldn’t normally appear in their meat-based counterparts. As such, producers of pl...

Highlights and insights from Millers’ Day 2024

We cover the detail of the presentations given by our in-house experts, on ultra-processed foods, developments in cereal testing methods, and food allergen c...

Upcoming New Standard for Food Additives in China

Key amendments to be aware of in China’s new GB 2760-2024 National Food Safety Standard on Uses of Food Additives.

Safely achieving clean label products through thermal, non-thermal and emerging processing techniques

‘Clean label’ innovations require developers to strike the right balance between various considerations. The choice of processing also needs to be factored i...

Understanding and controlling the threat of Shiga toxin-producing E. coli

Looking at the difference between Shiga toxin-producing E. coli (STEC) and non- Shiga toxin-producing E. coli, and how to control these pathogens and prevent...

Control measures for tackling food fraud

Even though fraudsters continue to come up with new ways to both commit food fraud and evade detection, there are strategies that you can employ to protect y...

What are the regulatory considerations around ‘natural’ alternatives to additives in the EU and UK?

In the EU and UK, food additives need to undergo an authorisation procedure before use in food products. Here we cover how food additives are regulated, how ...

How to ensure robust challenge testing in process validations

Key considerations for conducting process validations, including challenge testing. Plus, some specific examples of how we help ensure that worst case is val...

Lessons learnt from previous food fraud incidents

Even if control measures appear robust, food business operators must not be complacent against the threat of food fraud.

Decontamination of herbs and spices – process validation and challenge testing for both established and emerging technologies

Herbs and spices can harbour pathogens but their quality can be negatively impacted by established decontamination processes.

How to defend your business against food fraud

Food fraud is a significant threat to any food or drink business operator and there are many food associated safety risks. Plus food fraud can have huge repu...

Tools for streamlined and successful product development

Two solutions to help your product development effectively and efficiently keep pace with market demand – facilitating a complete understanding of your produ...

Navigating the EU Deforestation Regulation and UK Forest Risk Commodities regulations

As well as addressing consumer demand for sustainably sourced products, food and drink manufacturers also need to navigate these new due diligence and tracea...

Highlights from the 8th Global Food Safety Training Survey – the industry can and should do much better

We summarise the 2024 key findings from this benchmark data training. The survey allows participant companies to compare themselves and share best practices....

The latest ‘greenwashing’ updates – responsible communication of environmental, sustainability and green claims

Outlining the latest regulatory developments in the EU, UK and other English-speaking markets, the challenges they present and how to approach them.

‘Hot topics’ top 5 – the key focus areas and industry challenges that our members are talking about

The hottest topics that were most discussed in our 2023 Member Interest Group (MIG) meetings, why these issues are ‘hot’, what the challenges are and how we ...

Our 2024 IFST Student LaunchPad event

Our most recent IFST Student LaunchPad event took place on 23rd February 2024, and here we cover how the day went. Plus what else we offer to support student...

Understanding and setting food and drink shelf-life in the GCC region

Covering what the GSO is and its role within the GCC, how food and drink shelf-life is regulated in this region, and how to overcome the challenges that this...

Grain steeping throughput and water usage – the impact of pulsed electric field technology

In line with the brewing industry’s interest in exploring ways to increase productivity and save energy, without compromising final product quality, we have ...

The importance of TACCP

Richard Leathers, Global Quality Lead covers the importance and key features of TACCP – needed to protect your food business from food fraud and deliberate a...

5 drivers impacting global food safety

As the transformation in the way we produce, distribute and consume food continues, there is a need for effective and proactive food safety management that k...

Preparing for 2024 – expected trends and challenges

What food and drink industry trends and threats are you preparing for as we head into the coming year? How will you and your business navigate the challenges...

Achieving sustainability and efficiency through new technologies

By adopting advanced technologies and best practices, manufacturers can improve the efficiency and sustainability of many different food and drink processing...

Innovate UK funded access to our services

Find out how eligible start-ups and SMEs can apply for £15,000 of grant funding to spend with us and others.

Pathogen risks to be aware of – lessons from recent recalls and outbreaks

An overview of the foodborne pathogens of concern in the food processing environment and the food chain, drawing on recent outbreak and recall information.

Agility for overcoming supply chain disruption

How to build resilience against supply chain challenges and threats, including the importance of having an agile and holistic food safety management system i...

Four ways to build supply chain resilience

Supply chain resilience enables businesses to protect themselves from negative impacts of supply chain threats, and thrive in an ever-changing environment. T...

What is organisational resilience?

As global and local factors continue to transform the way we produce, distribute and consume food and drink, business operators need to build resilience for ...

The power of using time-based sensory mapping with consumers to characterise your product

The power of sensory data from consumers. A guide to the key outputs of conducting time-based sensory mapping with consumers , the valuable applications of t...

Supply chain assurance, traceability, and raw material risk assessments

The importance of supply chain assurance, traceability and raw material risk assessments for ensuring resilience against supply chain threats.

Positive food safety culture and supply chain resilience

The importance and benefits of a positive food safety culture, including with particular reference to supply chain resilience.

BRCGS Global Standard for Food Safety Issue 9: most common non-conformances

Our thoughts on the most common non-conformances raised since audits against Issue 9 began in February.

Asking our network about their food allergen cross-contact concerns

We asked our LinkedIn network for feedback on allergen cross-contact via a number of poll questions about their concerns in this area.

Q&A: investigating off flavours and taints

Our experts share their knowledge of off flavours and taints, and how they can support you in this area.

Leveraging sensory insights throughout the product lifecycle

Explore the benefits of applying sensory analysis to produce robust sensory data and make more informed commercial decisions, as well as the risks of not inc...

The benefits of applying consumer insights

Whether developing a new product, optimising an existing one, or looking to leverage insights into consumer journeys, we can help you produce winning product...

Research, partnerships and accessing funding

Craig Leadley, Technology Fellow covers UKRI funding channels, connecting businesses to funding bodies and resources, the exciting research for which we have...

Food allergen management: what you need to know about the Codex code of practice

Roughly 3% to 10% of adults and 8% of children worldwide are estimated to have a food allergy. Cases of food-induced anaphylaxis, at times resulting in fatal...

Food allergen management and labelling – the food industry’s evolution

Helen Arrowsmith, Regulatory Affairs Manager and Allergen Specialist reflects on the industry’s evolution with respect to food allergen labelling and managem...

Food allergen labelling – the difference between ‘gluten’ and ‘cereals containing gluten’

Helen Arrowsmith (Regulatory Affairs Manager and Allergen Specialist), Christopher James (Safety and Quality Specialist, Allergens) and Lewis Wallis (Regulat...

Cultivating meat for space missions

Technology Fellow, Craig Leadley takes us through his exciting work with Kayser Space and Cellular Agriculture Ltd on a European Space Agency project to expl...

Four sources of food allergen cross-contact from throughout the food chain

Allergen cross-contact can occur at every stage of the food chain, from ‘farm to fork’. Among the many sources of risk that food business operators must cons...

Selecting the right method or test kit for your food allergen testing

With so many different food allergen tests available, it can be daunting to select the most appropriate option. We can help you.

5 reasons to optimise the pasteurisation of your beer and low pH beverages

Greg Rachon, Brewing Microbiology Section Lead, explains the benefits to beverage manufacturers of optimising their pasteurisation processes.

Are you following developments in precautionary allergen labelling and information?

This blog discusses precautionary allergen labelling/information (often referred to as ‘may contain’ statements) and details recent developments in this area.

Recent developments in alcohol labelling

One of our regulatory experts clarifies and simplifies some of the recent changes and developments in how alcohol labels need to be presented.

Using our manufacturing best practice service to support your certification

Hear from Richard Leathers about two very different factories to which he has provided Manufacturing Best Practice support to help the teams gain new certifi...

Are you getting the ingredients you paid for?

For more on analysis and testing, including rapid turnaround for urgent testing, visit our service pages.

Attending the Institute of Food Science and Technology (IFST) Spring conference 2023

IFST’s Spring Conference was on ‘Taming the Perfect Storm’ and the interconnecting health, nutrition, food security and environmental challenges facing our i...

Process validations for non-thermal and new technologies – have you validated the worst case?

We have explored factors outside those commonly considered in process validations, and found significant and substantial effects on the log reductions achiev...

FAQs: your shelf-life questions answered

In this Q&A, our experts detail the answers to the shelf-life questions that they are most frequently asked by clients.

An insight into working as part of the Campden BRI graduate programme

Some of our Graduate Scientists share their experience of the Campden BRI Graduate Programme – why and how they joined us, what they have gained so far and h...

Understanding and maximising the shelf-life of drinks

Understanding the quality deterioration that can occur to shelf stable beverages can help developers design their product and its production process to facil...

5 reasons to review product shelf-Life

Clearly shelf-life needs to be established as part of new product development, but there are plenty of other reasons why shelf-life must be reviewed – here w...

Setting shelf-life for ambient food and beverage products

Exploring shelf-life limiting quality parameters and considerations for setting a ‘best before’ date for ambient goods

Creating the texture that consumers want from plant-based alternatives to meat

Food microstructure affects texture and sensory perception. We can use information from imaging microstructure, alongside texture analysis and consumer insig...

What does your beer taste of? – the invaluable benefits of a sensory tasting panel

Sue Purcell, Sensory Training Section Manager and Beverage Consultant details how descriptive sensory panels work and the many ways that our Beverage Panel c...

How to build a convincing business case for your food or drink product optimisation strategy

How can you take your product optimisation strategy from concept to reality? Ultimately, you need backing from stakeholders. Here we provide four simple step...

5 ways to benefit from food processing improvement strategies

Food processing technologies improve the efficiency and safety of the processes used to transform raw materials into finished food and beverage products. By ...

Predictive modelling to determine shelf-life – what can it tell us?

Predictive modelling is a tool used to assess the survival and/or growth of a microorganism under a range of temperatures, pH and water activities.

Ingredient functionality: unlock power and control through detailed understanding

Knowing the purpose of each ingredient in your product, and what characteristics enable them to fulfil these, can help manufacturers to overcome challenges w...

5 ways to optimise the packaging of your food and drink products

Exploring five of the many ways that packaging can be optimised to maximise your food and drink product profitability. From directly reducing packaging costs...

Modified atmosphere packaging - 'The carbon dioxide effect'

Modified atmosphere packaging (MAP) is used as a means of preservation and is well known in the food industry as a method to extend the shelf-life of a range...

BRCGS Global Standard for Food Safety Issue 9: a guide to key changes

This short guide will help you to understand the key changes that have been made and how they will affect your business.

3 ways to cost-optimise your food and drink products to protect profits

Cost optimisation is one of two critical components of product optimisation, focussing on maintaining the value and quality of a product while improving its ...

Minimise costs and maintain quality: 4 steps to successful reformulation

Now more than ever, your products must deliver superior value and quality at the lowest possible price. Regular cost optimisation — even for products that ar...

So, you've optimised your product - but do your consumers agree?

Removing cost from your product can help to improve profitability, but you must also protect what your consumers value most. Conducting consumer research pre...

Strategies to maximise food and drink product revenue while maintaining quality

Do you want to stay ahead of your competitors by maximising the market potential and profitability of your products? To deliver unrealised potential from you...

Could your process benefit from pulsed electric field technology?

Danny Bayliss, New Technology Lead and Alicja Staskiewicz, Process Technologist share how pulsed electric field (PEF) technology works and the many ways it c...

5 reasons to proactively optimise your food and drink products

As the global population continues to increase, so do the opportunities for food and drink manufacturers and suppliers.

‘Use by’, ‘best before’, ‘display until’ – what’s the difference and why does it matter?

We’re all aware of the various date marks that appear on food labels, such as ‘use by’, ‘best before’ and ‘display until’. But, let’s look at what they actua...

What will 2023 bring for the food and drink industry?

What food and drink industry trends and threats are you preparing for as we head into the coming year? How will you and your business navigate the challenges...

How resilient is your supply chain?

Campden BRI has a long history of providing specialist advice to the food and drink industry on best practice for ensuring that supply chains remain resilien...

Major milestone for human food made with cultivated animal cells in the United States

The FDA announced that it has completed its first pre-market consultation for a human food from cultivated animal cells. The product, by UPSIDE Foods, is mad...

Want air fryer cooking instructions on pack? Here’s more detail from Greg Hooper, Instruction Services Manager on why this is such a challenge

Despite the popularity and success of air fryers, the variability of cooking performance currently presents a food safety barrier to cooking instruction vali...

Trialling plant-based replacements for egg in bakery

Due to consumer considerations around sustainability, ethics and health, the demand for plant-based products continues to rise. We have received a growing nu...

Health and nutrition claims for foods in Australia and New Zealand – and how these differ from those in the EU/UK

In Australia and New Zealand, nutrition content claims and health claims for foods are regulated by Australia New Zealand Food Standards Code – Standard 1.2....

Want air fryer cooking instructions on pack? Proceed with caution!

Despite the popularity and success of air fryers, they present a challenge to the industry with respect to on-pack cooking instructions.

Single-use plastic ban in the European Union

The EU Single-Use Plastics Directive is making big changes to food service packaging habits. With the EU member states taking a variety of approaches to put ...

Discover the solution for your failing product

Physical characterisation is important when analysing and measuring the ‘quality’ of food and drink products.

3 Reasons why food quality and safety can be compromised by packaging materials

Food packaging plays a crucial role in the quality and safety of food products. From the processing line to consumers' shopping bags, it has to protect food ...

Replacement of shellac in food

Since January 2022, the Vegetarian Society of the United Kingdom (UK) no longer permits the use of their trademark logo on new products containing the food a...

Things you need to consider when setting a shelf-life

Understanding shelf-life is essential in assuring the safety and quality of your food and drink products, and setting the correct shelf-life can be key to th...

Reducing Hepatitis E through thermal inactivation

With concern about the level of cooking required to eliminate HEV from potentially contaminated food, Campden BRI have been part of a major Food Standards Ag...

Challenge testing of canned drinks - Are yours microbiologically stable?

With product formulation, processing technologies and transport exposing canned drinks to microbiological risks, understanding if a product is microbiologica...

Nearly 70% of respondents consider cross-contamination the biggest challenge when dealing with food allergens

When asked in our recent poll, ‘What do you consider to be the biggest challenge with allergen management?’, an overwhelming 68% of respondents chose cross-c...

4 ways to reduce food and drink product costs and boost revenue

The cost of commodities, including raw materials, continues to rise sharply, affecting margins. With the situation set to continue well into 2022, there are ...

Pet foods and the unknown risk to human health

Over the years, the pet food industry has suffered several foods scares resulting in adverse health effects to those owning pets and financial impacts. In th...

Bubbles in bread and aerated chocolate – it’s just air but it matters

Texture is one of the key elements to the commercial success of food. Developing or reformulating products typically requires the production and evaluation o...

Meat testing – ensuring quality and safety

Testing of meat and meat products can be used to assess quality, safety, performance and compliance with prescribed standards, both external and internal, an...

Ensure product safety through process validation and challenge testing

Food Business Operators must validate their microbial kill steps. When the process does not allow for the use of temperature sensors, or there is a lack of a...

Alternative and novel packaging: 4 key considerations

When we think about new packaging, it is important to consider the material, environment, and product. What are the key considerations with the use of these ...

Titanium dioxide: The reformulation challenge countdown has started

Titanium dioxide (TiO2), also known as E171, is widely used for optimising whiteness to foods. Following the adoption and publication of a new EU Regulation ...

Bans of perfluoroalkyl substances (PFAS) in food packaging gain traction: Get ready with PFAS testing

Governments around the world are currently trying to remove PFAS from the food supply, as well as the environment. A patchwork of new legislations in recent ...

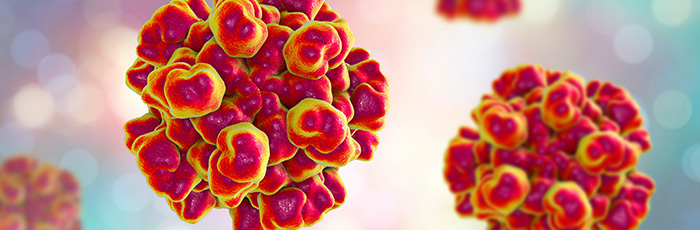

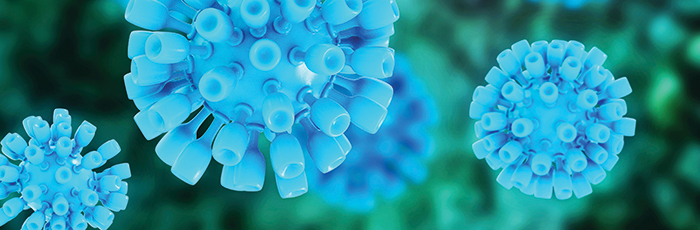

Viral Message: Norovirus causes greatest burden in UK pathogen ranking

Norovirus poses the highest burden on society out of 13 pathogens analysed in the United Kingdom.

Pulsed electric field processing: the potential in food processing

Pulsed electric field (PEF) is a well-known non-thermal food preservation technique that utilises high voltage fields to generate pores in cell structures. ...

Superchilled sustainability

Lesley Galpin, Head of Technical at Lyons Seafoods, shares her key learning around the implementation of superchilling, as a method to extend the shelf-life ...

Exporting to China? Register with the GACC to comply with new food products regulation.

This year, the General Administration of Customs of the People’s Republic of China (GACC) released Decree No. 248 and Decree No. 249, with a view to regulate...

5 food packaging trends during 2021

In 2021, the Packaging Industry was not only plagued by the pandemic but faced additional pressures. In this round-up, we will consider some of the big issue...

How power ultrasound helps you improve processing

As many companies look to improve the efficiency of their processes and reduce energy and water usage, ultrasound has emerged as an assistive technology for ...

Flexible mono-materials packaging challenges

Traditional mono-material packaging requires refinement to ensure that they perform at the same level as multi-material counterparts. ...

That’s a wrap - reducing food waste through sustainable and smart packaging

While packaging waste is a critical issue, it must be considered alongside the issue of food waste. Projects in food packaging, such as the Glopack project, ...

Sowing the seeds of success for plant-based product

With the growing adoption of plant-based diets, is your NPD capitalising on recent trends and meeting the expectations of an increasingly discerning customer...

List of food recalls for ethylene oxide grows

European countries and the UK are facing more ethylene oxide related recalls after the substance was detected in more food additives used in a large range of...

Considerations for optimal food barrier packaging

With a growing variety of new and established materials, each with specific characteristics, increases the potential for selecting unsuitable packaging mater...

Problem solving: Paper straws in drinks

There have been some concerns about the quality of plastic straw replacements – particularly when it comes to paper straws. The key issues pointed out by con...

The future of food – what innovative products are students developing?

A promising way to spark innovation and bring a new perspective to NPD is to have passionate students design - from scratch - new, inventive food products.

Wheat varieties – how they differ and the impact on end-product

Looking to reach more consumers with wheat-based products that originate from other countries? A crucial step to this is making sure you’re using the right w...

Cutting down on food waste while maintaining food safety

How can you cut down the food waste in your food business while ensuring food safety? Find out with these tips from our experts.

Eggs: Just how crucial are they in baked goods?

In this blog our expert Sarab Sahi uncovers the many functions of this ingredient to help you understand how vital they really are.

4 key steps to ensure NPD success with alcohol and no/low alcohol drinks

Right now, the alcohol and no/low alcohol markets are booming, but is your NPD capitalising on recent trends and reaching the growing band of consumers?

Food innovation and product design – 5 key considerations to create products consumers will love

Consumer choice has never been greater. How can you continue to capture the consumer’s attention in a saturated market and ensure your product’s success?

The digitisation of processing – what role does Industry 4.0 play?

What are the benefits of applying Indsutry 4.0? In this blog we use a recent case study to demonstrate how introducing Industry 4.0 to an SME bakery boosted ...

Contamination issues: Which foods are prone to which pathogens? And why?

Which foods are prone to which pathogens? Knowing this can help you prepare to prevent issues from specific pathogenic organisms.

Choosing the best packaging in a post-pandemic world

The world has changed, but does your packaging need to too? Find out about the new technologies that can help you decide.

Switching to metal packaging? What you need to consider

There are many reasons why manufacturers are looking to move from plastic to metal packaging. Here we explore the considerations before making this transitio...

How is the industry demonstrating control of Listeria? Survey reveals all

Do you struggle to demonstrate control of Listeria to customers and enforcement authorities? You’re not alone. Find out how we’re helping the industry with t...

New guideline for heat preserved foods in progress

Do you use heat to preserve foods but lack up-to-date guidance? We’re currently revising guidelines to help the industry manage risk in this area with the be...

Emerging technologies for food powder decontamination

Do you decontaminate powders? What technologies are there and what must you consider before selecting the most appropriate one? Find out in this new blog by ...

Gut microbiome and health – what’s the impact of baked goods?

With consumers focusing on eating foods that promote their gut health, it’s important to know how foods impact the gut to understand how to develop products ...

UK Salmonella outbreak - the chicken bites that bite back

You’ve likely heard of the UK’s large food poisoning issue associated with Salmonella enteritidis. It’s linked to certain retailer-sold breaded chicken produ...

Becoming CEO during a pandemic: An interview with our Chief Exec

Peter Headridge’s induction into the role of CEO at Campden BRI has been the ultimate baptism of fire.

Fish, seafood and its preservation: How can we extend shelf-lives?

Why are fish and seafood products so perishable? Here we explore that and how our new research project is attempting to increase the shelf-life of these prod...

Revised food safety guideline

Phil Voysey discusses the importance of a guideline on cleaning and disinfecting food factories, and the approaches taken to update one already in circulation.

How did COVID-19 cause food poisoning cases to plummet?

As we pass the one-year point in the pandemic, COVID-19 has appeared to have had a drastic effect on reported cases and outbreaks of food poisoning.

Just how healthy is bread? Expert reveals all

Demand for bread exceeded 50% at one point during the current health crisis, proving it as one of the UK’s favourite staple foods.

Enzymes as processing aids in bakery products

Enzymes are naturally occurring materials in plants and animals and are widely used in the manufacture of bakery and other products that make use of modern f...

What causes bread dough to rise?

A great deal is written about the way that yeast produces carbon dioxide to leaven bread dough during proof. However, there are other gases such as ethanol a...

Food delivery is on the rise – but is it always safe?

COVID-19 has obviously been devastating for almost every aspect of the food industry, but perhaps a calling for food delivery.

Decontaminating with UV-C light? Here’s what you need to know

As businesses look for new ways to combat the virus that causes COVID-19, the application of ultraviolet light has seen an incredible uptake.

Applying Industry 4.0 to reduce energy consumption and bakery food waste

Bread is one of Britain’s most wasted foods, around 24 million slices of bread are thrown out by UK households every day.

The challenges of reformulating with plant-based proteins

Demand for plant-based alternatives to animal-origin ingredients in bakery products has grown significantly in recent years.

5 things to consider before validating your thermal processes during COVID-19

It’s essential that your thermal processes are validated correctly. Find out from our expert what you need to consider before validating your thermal processes.

Mushroom-related outbreaks – what caused them?

Salmonella, Listeria and Staphylococcus have all been linked to mushrooms, even as recently as this year.

What’s hot in food microbiology? Conference reveals all

As COVID-19 continues to impact the food and drink sector, our team at Campden BRI held a three-day online conference to help the industry.

Sprouted grains – the challenges of using them in baked goods

Sprouting has attracted attention recently due to its potential to improve digestibility.

What effect does novel packaging have on microflora?

Today’s food packaging landscape is driven by the desire to minimise environmental impact while maximising shelf-life and presenting products attractively to...

E. coli vs. Shiga toxin-producing E. coli - what’s the difference and what’s the problem?

confused about the terms used for different groups of Escherichia coli and their relative food safety risks?

New technology to detect bread quality

The industry’s use of computer vision systems is growing – especially for detecting food quality issues.

Food colour – just how important is it?

Colour is one of the most important sensory aspects of food and drink. As well as indicating its likely freshness and flavour,

Antimicrobial onions – which pathogens could they conceal?

It won’t surprise you that these eye-irritating bulbs contain a chemical molecule that bears antimicrobial activity.

Remote auditing to help you manage risk during the COVID-19 pandemic

COVID-19 has created global issues that have dramatically impacted food business operators.

Pathogenic E. coli in flour: A food safety hazard?

Early in 2020 the German Federal Institute for Risk Assessment (BfR) published an extensive paper on the sources, risks and prevention of pathogenic E. coli ...

Using natural thickeners to achieve clean label products

If you’re like most people, then picking up a product to find unfamiliar, chemically synthesised ingredients on the back is a big turn-off – it may even diss...

Does your cleaning kill the COVID-19 virus?

Companies want to be sure that their cleaning inactivates the virus that causes COVID-19.

Reducing sugar with extruded flour

When did you last consume some sugar? Chances are it was probably today. It’s a difficult ingredient to avoid,

Can we assume consumers’ fridges are at a safe temperature?

Current UK Food Standards Agency guidance is that chilled foods should be stored at 5°C throughout life even though the legal maximum temperature for chill i...

Reducing portion size - how low can we go?

Obesity remains a problem in the UK, and product downsizing is just one of the ways we can try to help. It also offers an effective cost optimisation strateg...

Intelligenc dough mixing using AI

The subject of bread making was one we thought as ideal for applying AI to model the process

Listeria lessons

Over the past year Listeria appears to have re-emerged as an organism of great importance, with a number of high-profile outbreaks.

Comparing products for NPD and market success

Changing a product’s recipe, process, shelf-life or packaging can be a daunting task.

Sampling for food safety – are you doing it correctly?

Discusses the importance of sampling correctly to prevent microbiological issues.

3D printing of food

3D printing is a rapidly growing technology that is already in widespread use for customised,

Environmental monitoring – are you complying with BRCGS Issue 6?

Manufacturers of food packaging materials are now required to implement a microbiological environmental monitoring program, where appropriate, based on risk.

Reformulating with food ‘waste’ to double fibre content

As part of our research into calorie reduction and fibre enhancement, we successfully used food waste to double the fibre content of a tortilla.

Single-use plastic packaging challenges

We’re currently undertaking a member-funded project to investigate the technical challenges of reducing or replacing single-use plastics for food and drink.

Process optimisation: baking with enzymes

Enzymes are natural biological catalysts that speed up and improve the chemical reactions required in the baking process.

The benefits of proficiency testing schemes in brewing

The Brewing Analytes Proficiency Scheme (BAPS) is an international scheme designed to promote quality in the measurement of a range of chemical, microbial an...

New way of assessing shelf-life for chilled products

E. coli, Salmonella, Listeria – we’re all aware of the ‘buzzword’ bacteria, but we pay less attention to all the other countless species that naturally occur...

Solid-state microwaves – the future?

The introduction of microwave heating food in the 1940s sparked a revolution in the way we process foods both commercially and domestically.

Nutrition, diet and health – challenges faced by the bakery sector

There are many challenges to improving the nutritional profile of our diets, including reduction in the fat, salt and sugar content of food products together...

Chorleywood Bread Process – how it’s changed industry

If there is an iconic baking process that has come out of the British tradition, it would be the Chorleywood Bread Process (CBP) developed in 1961 by scienti...

5 ways Campden BRI can help you with your thermal process validation

Are you a manufacturer who applies heat to food? If so, it’s likely you’re applying a thermal process to reduce the level of microorganisms in your product, ...

Texture analysis – getting it right

Crispy, crunchy, chewy, firm, soft – all appealing adjectives found on food packaging - but what’s the importance of measuring how crunchy or how firm a food...

The importance of food colour and the challenges of clean label

Colour is one of the most important sensory aspects of food and drink. As well as indicating its likely freshness and flavour, it can also influence consumer...

Modelling and simulation of food processes

Simulations enable the effects of process conditions to be evaluated and optimised computationally prior to experimental validation

Are fridge temperature assumptions correct?

New research indicates that assumptions about fridge temperatures may not be accurate. Linda Everis, principal research officer at Campden BRI explains its i...

Cake fluffiness defined?

Cake ‘fluffiness’ is commonly used as a desirable quality for cakes and the term is regularly used in adverts and on the packaging of cake products.

Are your cooking instructions correct?

Instruction validation relates to the need to ensure that cooking and heating instructions for consumers are tested rigorously, to ensure that food is safe t...

Rapid confirmation and identification of Campylobacter in foods

Campylobacter are of great importance to the food industry as the major cause of bacterial food poisoning.

Repurposing waste for ingredients: reusing and recycling food materials

‘Getting more from less’ was a major ‘need’ articulated by our members when we asked them what they needed from science and technology. We’re all aware of th...

What are the benefits of continuous microwave processing?

Continuous microwave processing uses this mechanism to heat a product as it continually flows through a chamber.

Flavour and taint troubleshooting with food and drink

Problems with taints and off–flavours can cost food and drink companies considerable money and time through wasted product, impact on reputation and lost pro...

How can you meet the meat-free trend?

The trend for vegan food has spread quickly through the market, with meat alternatives and dairy alternatives proving popular with consumers

Cannabidiol in food and drink – what are the issues?

Ingredients derived from hemp (Cannabis sativa) are stimulating innovation in a wide range of food and drink products.

How to validate emerging technologies in food processing

Process validation is the collection and evaluation of data to establish that a process is capable of consistently delivering a safe product.

Considerations for determining shelf-life

Assigning the correct shelf-life requires a great deal of thought. Obviously, if it is too long there is the potential for food spoilage or growth of food pa...

5 things to consider when thinking about factory design and hygiene

A well thought out factory design that considers the ease of cleanliness at the outset can lead to the reduction of food contamination and food poisoning inc...

How and why do we measure the chilli heat of food?

A new method has been developed to give manufacturers and retailers confidence that they are providing consumers with accurate and consistent information abo...

Pasteurisation of beer achieved using significantly fewer pasteurisation units

Optimising pasteurisation for different beer styles and microorganisms is likely to result in reduced costs, lower energy utilisation and decreased water was...

Physics in food manufacturing

An initiative from the Institute of Physics (IOP) recognises the food industry as an important sector

Sausages NPD

Unusual fillings like wild boar and chorizo are now regularly available alongside more traditional pork or beef sausages and meat-free recipes.

Calculating duty correctly

Duty is paid when goods are brought into a country or trading area. Rates of duty are different for different commodities and different origin countries.

Why test for vitamins?

Vitamins are important nutrients that your body needs to function correctly and remain healthy.

Understanding presumptive positives in meat testing

The majority of Escherichia coli strains are harmless and are generally seen as hygiene indicators in the food industry.

Plastic packaging alternatives – what you need to know

The food sector is looking at alternative materials and systems to reduce the use of plastic packaging.

Solve your food product problems

We are often approached by clients with questions related to the appearance, texture and rheology of their products.

BRC Global Standard for Food Safety Issue 8: a guide to key changes

The BRC Global Standard for Food Safety is the most widely used of the commercial standards for assuring production of safe food.

Surprising benefits of tailored training

By 2025, it is predicted that the UK food and drink industry will need 130,000 new skilled workers to meet demand and replace retiring workers.

Hepatitis E - your common questions answered

Hepatitis E produces inflammation of the liver, which is caused by infection with the Hepatitis E Virus (HEV).

Save money without compromising your product

Increasing competition, rising ingredient prices and value-conscious shoppers are squeezing profits in food manufacturing.

Five things to get right when making a sensory claim

It is becoming increasingly important for producers to differentiate their products in a way that will provide a competitive advantage and entice consumers t...

Changes in approval of novel foods

The new Novel Foods Regulation (2015/2283) applies from 1 January 2018 and revoked the previous legislation that had been in force for 20 years.

Maximise your chances of a successful product launch

The trade press and market research reports are filled with sobering statistics about new food and drink products failure rates, but this doesn’t tell the wh...

Nutritional labelling of alcoholic drinks

Labelling of ingredients and nutrition information on most alcoholic drinks has long been voluntary in the United Kingdom, European Union and most world mark...

Regulatory considerations for sports foods

The majority of 'sports' products including protein powders and drinks are now regulated as ‘normal’ foods.

Five pet food innovation trends to watch in 2018

Pets are big business: in the UK alone there are some 58 million, with an estimated 46% of households owning a pet.

How can enzymes make baked goods healthier?

The baking industry faces many challenges in providing products that meet the needs of modern consumers, especially since baked goods are often seen as indul...

Upskilling the baking industry to help meet the sugar reduction targets

By 2025, it is predicted that the UK food and drink industry will need 130,000 new skilled workers to meet demand and replace retiring workers.

Good hygiene starts with kitchen design

Hygienic design is essential to ensure that the cleanliness of a kitchen is easy to maintain.

Process development of retorted foods – your top three most frequently asked questions

Thousands of new food and drink products are launched in the UK each year. Many of those products will require a company to purchase a retort/autoclave cooker.

Arsenic – complying with new limits in food

Arsenic is known to be harmful to health, but not all forms of arsenic are equally toxic.

The top 5 HACCP food audit non-conformances and how to avoid them

Your HACCP plan is there for a reason. Not complying with it is considered a non-conformance.

Food colour – it's more important than you think

Colour is one of the most important sensory aspects of food and drink.

Pulsed electric field - the potential in food processing

Pulsed electric field processing is a well known non-thermal food preservation technique, but did you know it can also be used to improve product quality and...

Developing food for the ageing consumer - six things to consider

It's no secret that the average age of the European population is increasing - the over 60s now account for nearly a quarter of the total population.

Protein profiling - how can it improve food safety and traceability?

We've recently started a new three year member-funded project looking at the use of protein profiling for assessing food safety and traceability.

Fast track food innovation

'Food development', 'new product development', 'product innovation' – whatever you call it, developing new successful products is essential for food and drin...

Fibre - an innovative approach to healthier baked goods

There is considerable evidence linking poor dietary choices to higher risks of obesity, diabetes and cardiovascular disease.

Five common process validation mistakes

Process validation is the collection and evaluation of data to establish that a process is capable of consistently delivering safe product.

A fresh look at microbial contamination

One of my early experiences as a food microbiologist was a visit I paid to a bread bakery that was having problems with a salmon-pink-coloured mould growing ...

Aseptic processing - process and hygiene

The aim of aseptic processing is to produce a sterile product through heat processing.

Ergot mycotoxins

The European Commission is intending to propose maximum levels for ergot alkaloids in unprocessed grain in 2017.

Analytical methods - using GC-MS to assess wine quality

Since I began working in the UK wine industry in 1976, I have tested and advised on tens of thousands of wine samples.

Pasteurisation of novel alcoholic beverages – striking the right balance

Contamination of beer by spoilage micro-organisms remains a considerable challenge for the brewing industry.

The challenge of NPD

Successful businesses need to innovate and introduce new products that are appealing, safe and produced at a cost that the consumer is willing to pay

Meat snacks product development

Traditionally seen as small portions eaten out with meal times, they may also be incorporated into the main meal, especially lunch, providing opportunities f...

Training Matters - Future of Training

VUCA doesn't sound very nice... but it is a great way of describing the world we live in: Volatile, Uncertain, Complex and Ambiguous.

Fresh produce decontamination

In recent years, the consumption of fresh fruit and vegetables has increased, largely due to advice on healthy eating and because exotic varieties of both ar...

Integrating the Packaging and Product Experience in Food and Beverages

Packaging is so much more than just a means of getting products safely to consumers.

Checking processes work

Validation of processes is an essential part of the manufacturing of food and drink.

Mathematical Modelling - Get a slice of the action!

Have you ever considered using mathematical modelling to simulate your own process?

Japan – a gateway to Asia

Choosing the right market when exporting food is an exciting yet challenging task.

Challenges in microbiological identification

Julie Archer, Microbiologist discusses some of the common issues and challenges in microbiological identification

Introduction to the China National Food Safety Standard for Uses of Food Additives

In order to strictly regulate the use of food additives and food flavourings and re-build the confidence of consumers, China has now streamlined its food sup...

In pursuit of baked-product quality

The word ‘quality’ means different things to different people, but on the whole, when it comes to buying baked goods, consumers tend to talk about ...

New EU Regulation to speed up approval of Novel Foods

A new EU Novel Foods Regulation (EU) No. 2015/2283 will come into force on 31st December 2015 and apply from 1 January 2018.

Safeguarding dry ingredients

Studies have shown that levels of Salmonella artificially inoculated on nuts were largely unchanged after 18 months

Packaging issues relevant to product reheating

Product reheating is the warming of ready-cooked foods by consumers and food retailers.

Foodborne viruses – the known unknowns

While the microbiological hazards posed by Listeria, Salmonella, Campylobacter and E.coli in food are well known.

Analysis of chlorate and perchlorate in beer

Following our development of a method to simultaneously determine levels of chlorate and perchlorate in food and drink, the British Beer and Pub Association ...

Exploiting the Asian market

Attractive incentives and extensive support are available for companies interested in reaching or supporting the food and drink market in north-east Asia.

Identification of physical contaminants in food

Foreign bodies form the biggest single cause of consumer complaints received by many food and drink manufacturers, retailers and enforcement authorities.

Successful product launch

Did you know that over 8,000 new products are launched in UK retail stores every year? But how many of these remain on shelves post launch.

Supply chain assurance

Thanks to the global supply chain, consumers today have an abundant supply of food all year round.

Sensory marketing

There has been significant growing interest in the role of cross modal sensory experiences in consumer brand and product choices and decision making.

Nutrition, health and wellbeing: the consumer perspective

Over the last 5 to 10 years there has been a growth in research and media attention in the areas of health, nutrition and well-being from the perspective of ...

New Product Development: Safety first

Over recent years, there has been much development of new food and drink products which are lower in salt, sugar and fat and thus offer a healthier option to...

The role of the pilot plant

When designing healthy products with reduced levels sugar, fat or salt, or increased levels of nutrients such as vitamins, minerals and fibre, initial small ...

The importance of ingredients

Nutrition, diet and health are currently hot topics for the food industry.

Technology innovation, development and validation

In a world which is constantly changing, manufacturers must adapt to stay ahead of competitors and continue to meet consumers' needs.

Microbiology process hall

We have been most fortunate to have had the opportunity to expand our facilities to include a process hall dedicated to microbiological studies.

Product and ingredient development trials

Developing new products and ingredients often begins with a small-scale bench-top exercise.

Enzymes as processing aids

The baking industry faces a number of challenges in providing products that meet the needs of modern consumers.

Drinks new product development

The alcoholic drinks sector, spirits in particular, is currently going through a very innovative phase.

Optimising quality in product reheating

Reheating instructions on product labels are developed from a 'safety first' viewpoint, but there is much that can be done to optimise quality without compro...

Are your packaging specifications suitable?

The packaging specification will cover a range of materials from the primary packaging through to secondary and tertiary packaging.

Food contact materials

Food contact materials (FCMs) are all materials and articles intended to come into contact with food or drink.

Preparing a due diligence analysis plan for a brewery

A food safety analysis (due diligence) plan provides a risk-based approach to food safety analyses.

Complying with Microbiological Criteria

The production of safe foods is a priority for all manufacturers. The adoption of systems such as Good Manufacturing Practices (GMP) and Hazard Ana...

Thermal process validation – always a hot topic

Verification is a key requirement for safe food production and confirms that a food safety system based around HACCP is working effectively.

Food borne virus detection

Over recent years there has been an increase in the level of food borne illness associated with food contaminated with viruses.

Detection of Shiga Toxin producing Escherchia coli (STEC)

There are hundreds of serotypes of E. coli. Many can be found in the intestines of animals.

Nutrition and health: Encouraging healthier food choices

It is well–known that lifestyle–related non–communicable diseases are now the leading cause of death globally.

Surrogates for process validation

In my blog this time last year, I mentioned in passing the use of surrogate microorganisms in process validation regimes.

Benchmarking accredited!

The importance of benchmarking cannot be overstated. That's why Campden BRI is proud to have UKAS accreditation for its benchmarking method, which provides a...

Incorporating consumer responses to food and beverage product development

In a developed market, the success or failure of a product will ultimately depend on what the purchaser or final consumer thinks of it.

Brewing NPD by Reverse Engineering

There are many reasons why we are approached to assist in new product development (NPD) for brewing and alcoholic beverage manufacture.

Product development and the Responsibility Deal

The Public Health Responsibility Deal is a government–led initiative to tap into the potential for businesses and other influential organisations to make a s...

The FIC is making plenty of work for us, too!

Food legislation is a complex area, with plenty of pitfalls for the unwary.

Using lower protein wheat for bread making

The level and characteristics of protein in wheat have a major bearing on its suitability for use in bread making - small differences can have a significant ...

Intervening to change behaviours

One of the issues facing governments and industry in general is how to persuade people to change their habits to what is believed to be a more desirable situ...

Ensuring reliable microbiological analysis

The results from microbiological analysis play a critical role in the effective management of food safety and quality, and it is vital that the user of such ...

Chemical analysis moves on

Recent developments in techniques under the broad umbrella of chemical analysis have allowed us to investigate and solve problems that were previously diffic...

The microbiology of process validation

The evaluation of the effectiveness of any food preservation process to reduce the target microbiological population is complicated.

The pivotal role of the pilot plant

Large numbers of new products are launched on to retailer shelves every year.

Hygiene and draught beverages

Even though drinks manufacturers may have produced immaculate beverages, the drink presented to the customer may be unacceptable if contamination has occurre...

Choosing the right disinfectant

When choosing the right disinfectant to use in a food manufacturing or similar area, there are several considerations to bear in mind.

Hygienic design and practices

The primary concern of food manufacturers is to produce a product that is both safe and wholesome.

Benchmarking seems to be the 'in' thing!

During the past year, interest in our benchmarking services – either with our "expert in-house panel" or using respondents from our consumer data base – has ...

Encouraging the consumption of frozen fish

Understanding what the consumer wants is very important when trying to develop successful new products - but it is also a key component in the promotion of p...

Carbon footprinting of your operations

In June 2012 the UK Government announced its decision to introduce mandatory carbon reporting for large companies listed on the London Stock Exchange.

How do you measure enzyme performance in the cereals industry?

Enzymes are being widely used in the cereals industry to improve processing performance and product quality in a range of food products.

Looks good, tastes good...

Sports drinks aim to provide water, energy and electrolytes in a form that is both palatable and easy to absorb.

Salt – the ultimate multifunctional ingredient

It is about 12 years since I was asked by the Food and Drink Federation to do an independent review of the literature on the technological functions of salt ...

Traceability

Traceability is a widely used term and is one of those broad concepts, like quality, for which there are many definitions and applications.

BRC 6 brings major changes

The sixth edition of the BRC Global Standard for Food (BRC 6) has certainly caused many companies to re-evaluate some of their processes and procedures.

Trouble with taints

Problems with taints and off–flavours can cost food and drink companies considerable money and time - in wasted product and resolving the problem.

Identification of physical contaminants in food

The rapid and cost-effective identification of foreign bodies reported from food is an essential part of the investigation of contamination incidents in orde...

Reducing food and packaging waste

There is much talk about reducing food and packaging waste, and many companies have on-going programmes to look at this issue.

Innovative processing – if it's new, we're interested

With the drive still on for 'clean label' products and products that have fresh tasting characteristics with a good shelf life, the interest in 'new technolo...

All change on labelling requirements

The Food Information Regulation has finally been agreed. After much debate, we now know what changes to food labels are going to be required.

Is your laboratory safe and fit for purpose?

Microbiological analysis needs to be closely controlled for the user of the results to have confidence in their reliability.

Salmonella in dry foods

There is growing concern for the potential presence and survival of Salmonella in low–water–activity ('dry') products.

Risk assessment of raw materials

As the range and prevalence of hazards in the food chain continues to grow and food manufacturers increasingly look to global markets to source raw materials...

Developing cooking (heating) food product instructions for microwave and conventional ovens

Selecting the correct packaging and providing good heating or reheating instructions is as important to the quality and safety of heated product as is the ef...

The case for "Bake-off"

Baking is seen as a traditional industry and its detractors say that anything that is not 'traditional' is therefore 'not good'.

Food labelling: easing 'constructive tension'

The food label is the 'face' of most products. It is what people first see.

Challenge testing

Food safety is a major concern for everyone involved in the food industry from producers to policy makers and retailers to consumers, and it is imperative th...